Repair

Repairing the Diaphragm Valve

NOTE: The diaphragm (17C127 – EQ300, 17C128

–EQ600) can be replaced without removing the assembly from the panel. You will need an 8 mm Allen wrench for the EQ600S and a 6 mm for the

EQ300S.

1.Perform the Pressure Relief Procedure, page 8 .

2.Loosen all 4

3.Replace the diaphragm (natural rubber compound) and

NOTE: There are two shims between the diaphragm and the actuator. Keep the shims and reuse them (they do not come with the replacement diaphragm). Do not cause any

4.Insert all 4

5.Apply more than 80 psi (5.5 Bar, MPa) air pressure to the regulator inlet to cause the piston to retract.

6.With the piston retracted,

7.Release the air pressure.

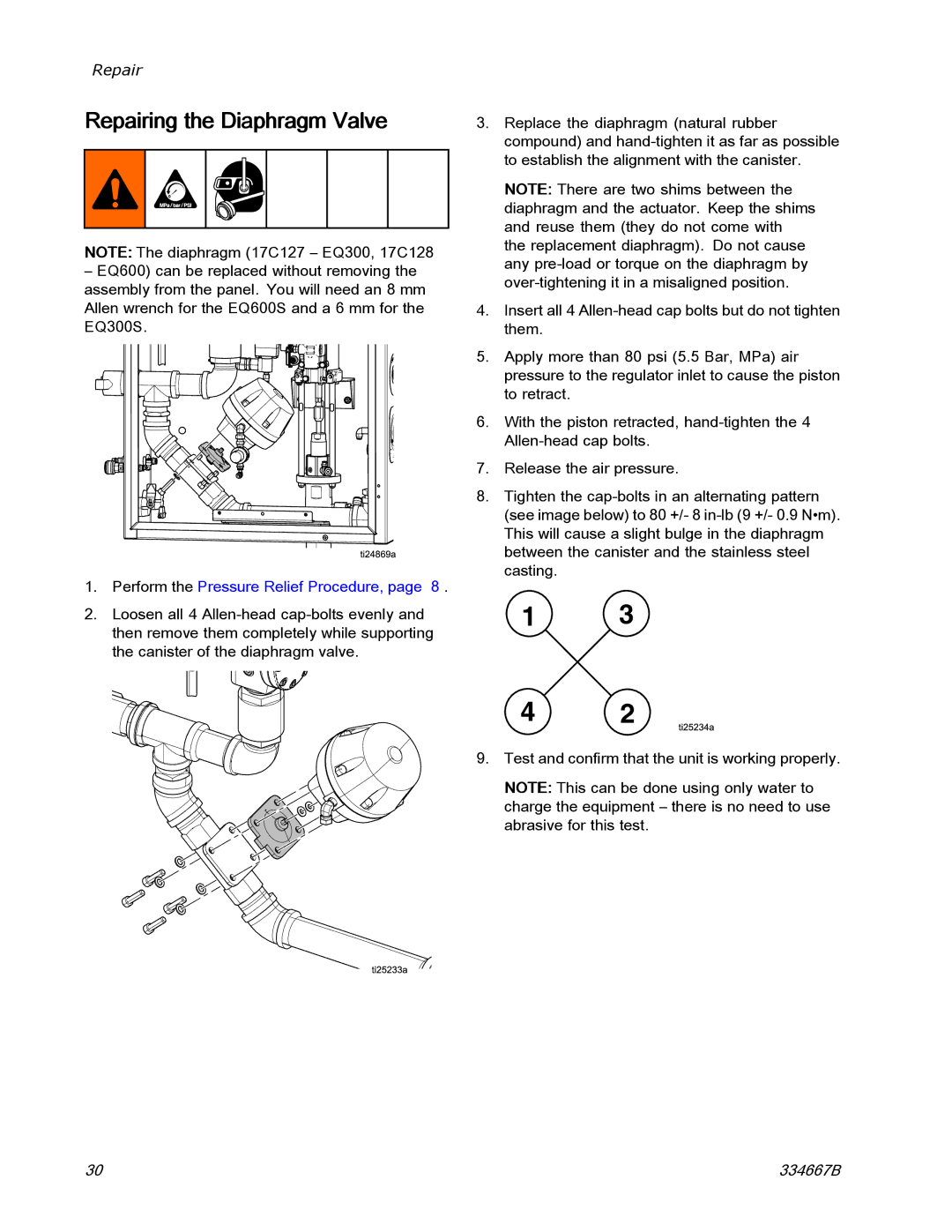

8.Tighten the

1 3

42

9.Test and confirm that the unit is working properly.

NOTE: This can be done using only water to charge the equipment – there is no need to use abrasive for this test.

30 | 334667B |