313516G

Important Safety Instructions

Automatic AirPro Spray Guns

Instructions-Parts

Orifice Size

Contents

Models

Application

Warnings

FIRE AND EXPLOSION HAZARD

EQUIPMENT MISUSE HAZARD

PRESSURIZED EQUIPMENT HAZARD

TOXIC FLUID OR FUMES HAZARD

PERSONAL PROTECTIVE EQUIPMENT

With Fluid Control Knob for fine adjustment of fluid flow

Selection Charts

General Metal Applications

TERMS

HVLP Guns

High Wear Applications

Wood Applications

Gun Selection

Proper Needle/Nozzle Selection

Air Caps

Conventional Guns

Air Flow

Atomizing Air

Fan Air

Atomizing Air

Fan Air

Maximum HVLP/Compliant inlet manifold pressure

Circulating System

Installation

Ventilate Spray Booth

Configure Gun and Manifold

Ground Spray Gun

Install Air Fittings

Ground Air Compressors and Hydraulic Power Supplies

Ground System

Mount Gun

Reciprocating Arm Rod Mount

Stationary Support

FIG. 5 Retrofit Adapter Plate Mount

Retrofit Adapter Plate

Setup

Connect Air Line

Connect Fluid Hose

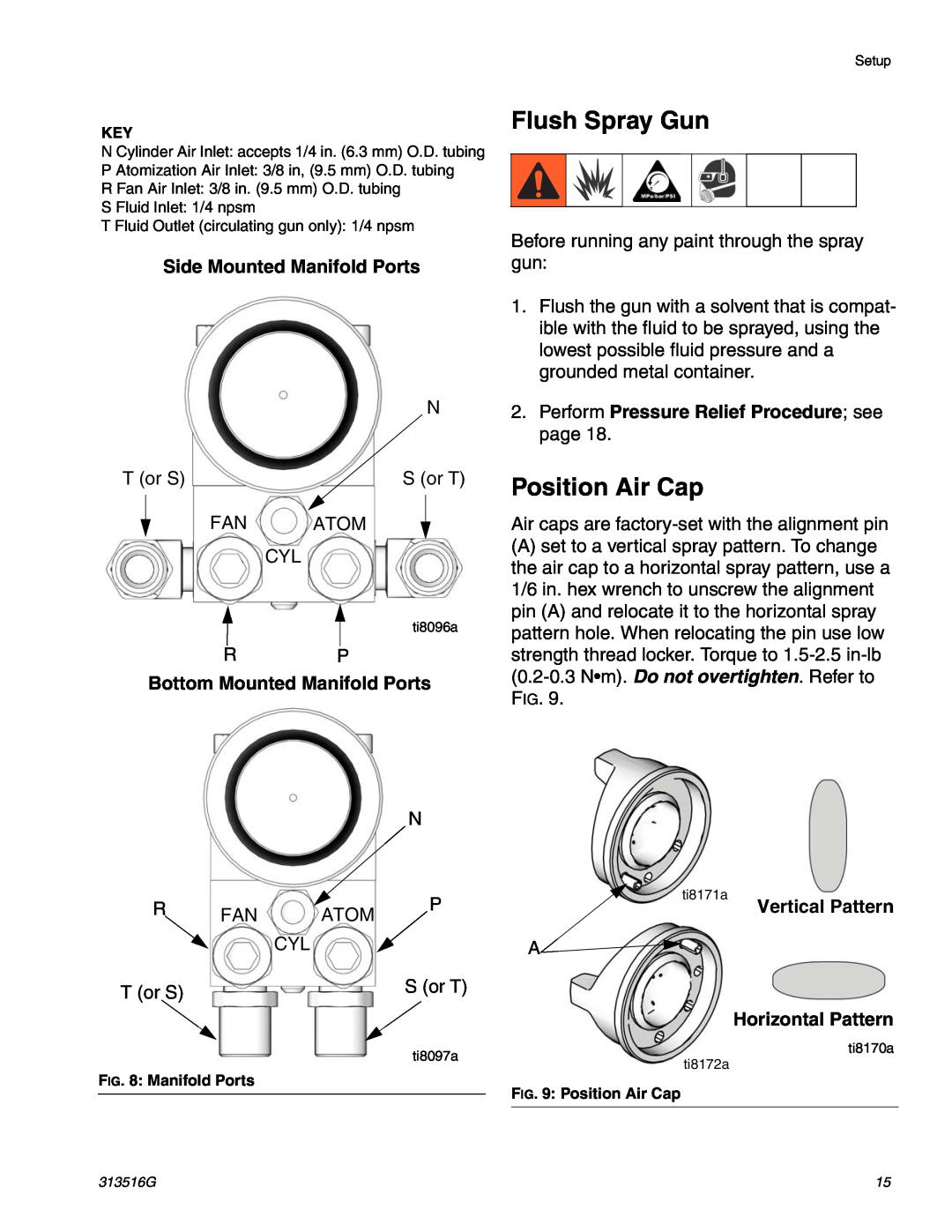

Bottom Mounted Manifold Ports

Flush Spray Gun

Position Air Cap

Side Mounted Manifold Ports

Fan Air psi

Adjust Spray Pattern

Table 1 Suggested Starting Settings

Atomization

NOTE HVLP and Compliant Gun Limits

Incorrect

Pressure Relief Procedure

Operation

Apply Fluid

Daily Gun Care

Clean and Flush Gun

General System Maintenance

Solution

Troubleshooting

General Troubleshooting

Problem

Problem

Spray Pattern Troubleshooting

Problem

Solution

Disassembly

Service

14. Perform the following applicable step

Reassembly

Parts

Parts

ti13593b

† Included in Fluid Seal Repair Kit 24B675 Not sold separately

Included in Air Seal Repair Kit

Size

Repair Kits

General Metal Applications

Orifice

Needle tip and nozzle exit constructed from tungsten carbide

High Wear Applications

Wood Applications

Model has Fluid Control Knob for fine adjustment of fluid flow

Manifold with bottom fluid ports

114101 103 107 105108

Not shown Not sold separately

Part No. 24C342

Not shown, optional size Not sold separately Part No. 288223 only

Part No. 24C342 only

Not shown, optional size Not sold separately Part No. 288217 only

North America Manifold with side fluid ports

International Manifold with side fluid ports

107 101 114 103

3 Torque to 110-130 in-lb 12.3-4.7 Nm

Not shown, optional size Not sold separately Part No. 288160 only

Part No. 288211 only

2 Torque to 8-10 in-lb 0.9-1.3 Nm

Alternate Nozzle Sizes

Accessories

Cleaning Brush

Replacement Gun 24A780

Tips

HVLP Pressure Verification Kit

Inline Fluid Filter 24B707

Spray Tip Filters

Dimensions

Manifold Models 288217 or 288218, All Gun Models

Manifold Model 288221, All Gun Models

Manifold Model 288160 or 288211, All Gun Models

Manifold Model 288223 or 24C342, All Gun Models

Two 0.13 diameter 0.31 in. 7.8 mm holes. Use 1/8 in. pin

Mounting Hole Layouts

Manifold Models 288217 or 288218, All Gun Models

Two M5 x 0.8 x 0.25 in. 6.3 mm holes

for alignment

Manifold Model 288221, All Gun Models

Two M5 x 0.8 x 0.25 in. 6.3 mm holes

Two 0.13 diameter 0.31 in. 7.8 mm holes. Use 1/8 in. pin

Four M6 x 1.0 x 0.34 in

Manifold Model 288223 or 24C342, All Gun Models

6.3 mm holes

Mounting Hole Layouts

for alignment

Manifold Model 288160 or 288211, All Gun Models

Two M5 x 0.8 x 0.25 in. 6.3 mm holes

Two 0.13 diameter 0.31 in. 7.8 mm holes. Use 1/8 in. pin

ti8178a

Retrofit Adapter Plate

2.3 in 57.7 mm

Mounting Hole Layouts

Cylinder Air

Technical Data

Triggering Speed

Sound Data

Graco Information

Graco Standard Warranty

![]()

![]()