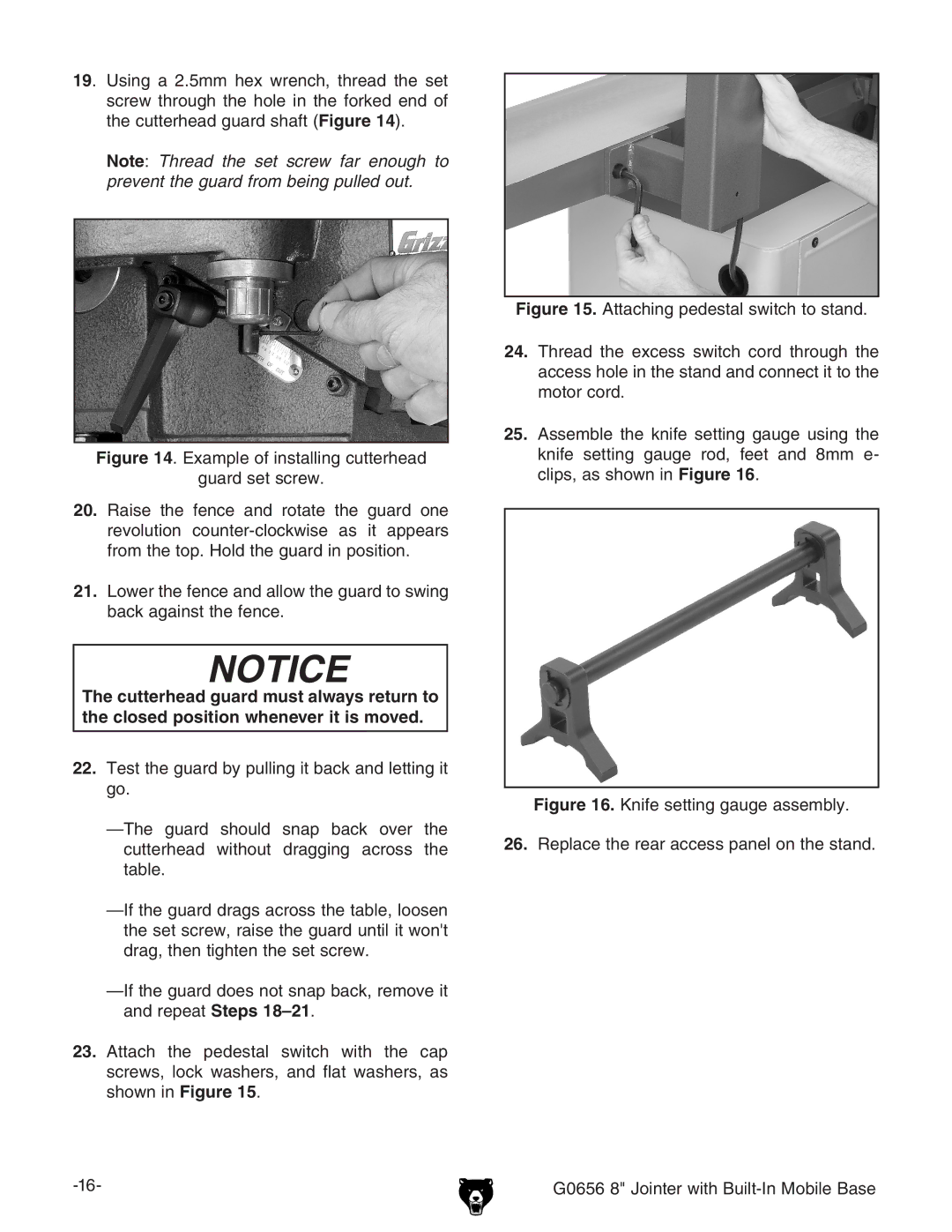

19. Using a 2.5mm hex wrench, thread the set screw through the hole in the forked end of the cutterhead guard shaft (Figure 14).

Note: Thread the set screw far enough to prevent the guard from being pulled out.

Figure 14. Example of installing cutterhead

guard set screw.

20.Raise the fence and rotate the guard one revolution counter-clockwise as it appears from the top. Hold the guard in position.

21.Lower the fence and allow the guard to swing back against the fence.

NOTICE

The cutterhead guard must always return to the closed position whenever it is moved.

22.Test the guard by pulling it back and letting it go.

23.Attach the pedestal switch with the cap screws, lock washers, and flat washers, as shown in Figure 15.

Figure 15. Attaching pedestal switch to stand.

24.Thread the excess switch cord through the access hole in the stand and connect it to the motor cord.

25.Assemble the knife setting gauge using the knife setting gauge rod, feet and 8mm e- clips, as shown in Figure 16.

Figure 16. Knife setting gauge assembly.

26.Replace the rear access panel on the stand.

G0656 8" Jointer with |