To bevel cut on the jointer:

1.Read and understand SECTION 1: SAFETY, beginning on Page 6.

2.Make sure your stock has been inspected for dangerous conditions as described in the Stock Inspection & Requirements instruc- tions, beginning on Page 21.

3.Set the cutting depth for your operation. (We suggest between 1⁄16" and 1⁄8" for bevel cut- ting, using a more shallow depth for hard wood species or for wide stock.)

4.Make sure your fence is set to the angle of your desired cut.

5.If your workpiece is cupped (warped), place it so the concave edge is face down on the surface of the infeed table.

6.Start the jointer.

7.With a push block in your leading hand (Figure 30), press the workpiece against the table and fence with firm pressure, and feed the workpiece over the cutterhead.

Note: If your leading hand gets within 4" of the cutterhead, lift it up and over the cutterhead, and place the push block on the portion of the workpiece that is on the outfeed table. Now, focus your pressure on the outfeed end of the workpiece while feed- ing, and repeat the same action with your trailing hand when it gets within 4" of the cutterhead. To keep your hands safe, DO NOT let them get closer than 4" from the cutterhead when it is moving!

8.Repeat Step 7 until the angled cut is satis- factory to your needs.

Rabbet Cutting

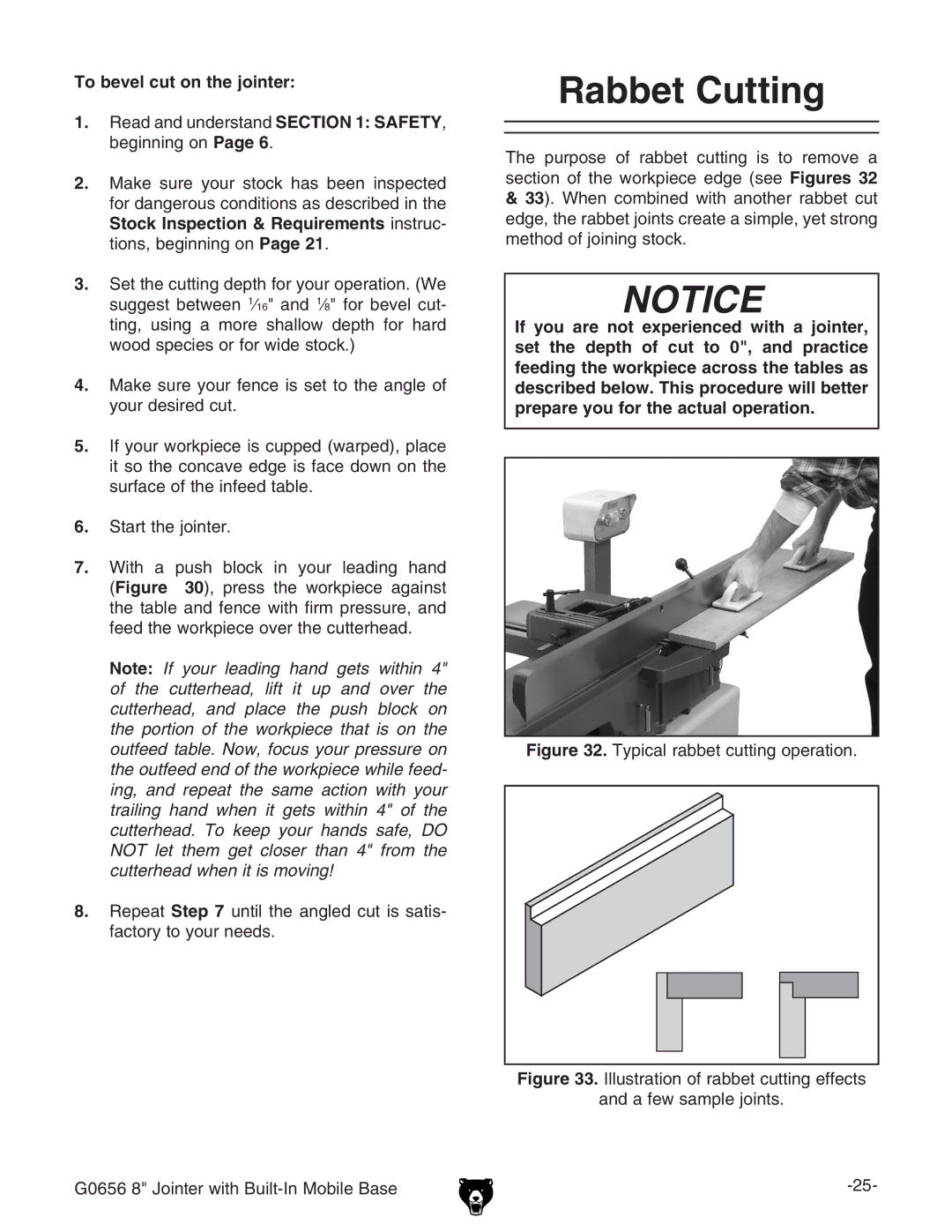

The purpose of rabbet cutting is to remove a section of the workpiece edge (see Figures 32

&33). When combined with another rabbet cut edge, the rabbet joints create a simple, yet strong method of joining stock.

NOTICE

If you are not experienced with a jointer, set the depth of cut to 0", and practice feeding the workpiece across the tables as described below. This procedure will better prepare you for the actual operation.

Figure 32. Typical rabbet cutting operation.

Figure 33. Illustration of rabbet cutting effects

and a few sample joints.

G0656 8" Jointer with |