Squaring Stock

Squaring stock involves four steps performed in the order below:

1.Surface Plane On The

2.Surface Plane On a Thickness

Previously

Surface

Planed Face

3.Edge Joint On The

4.Rip Cut On A Table

fence and the opposite edge cut off.

Previously

Jointed Edge

��

�� | �� |

Surface Planing

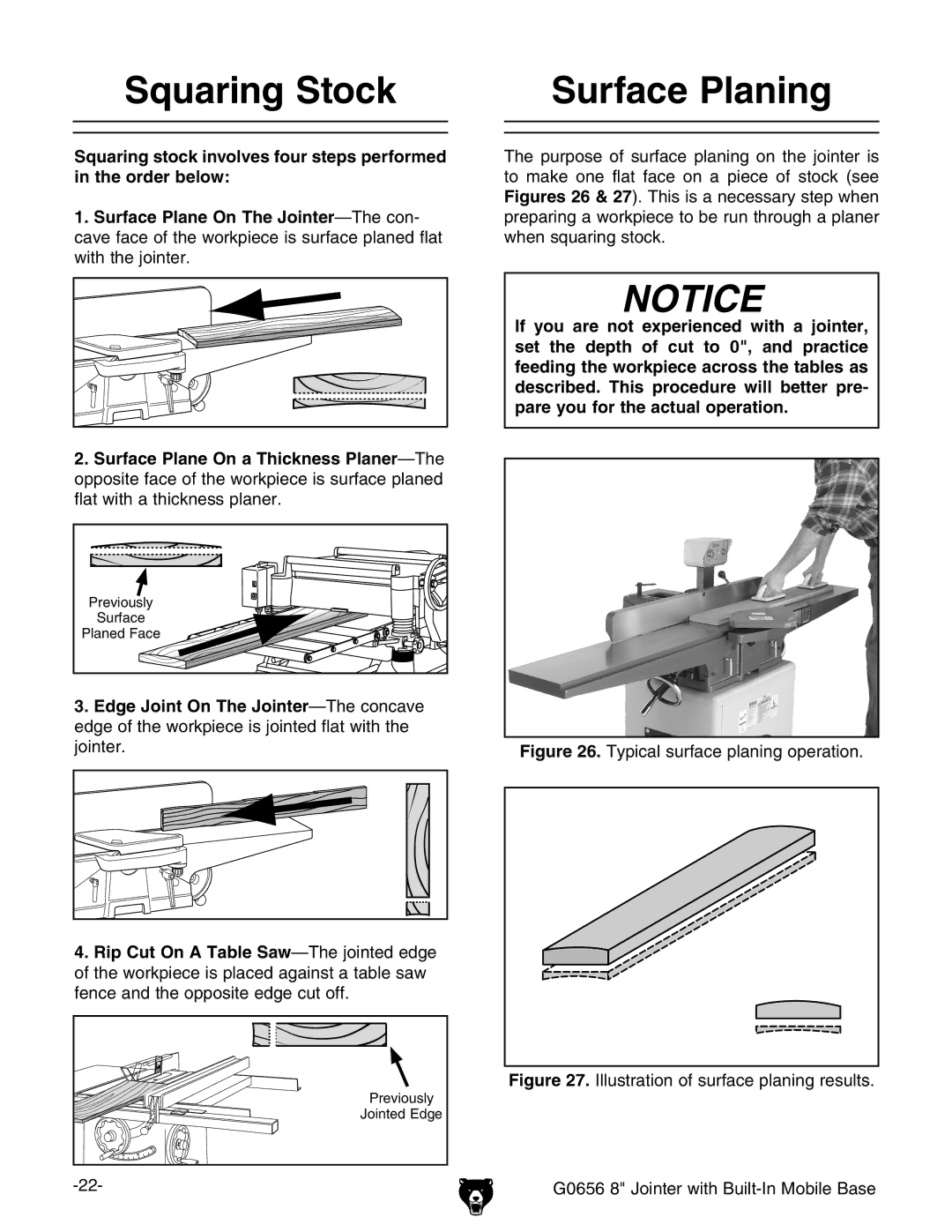

The purpose of surface planing on the jointer is to make one flat face on a piece of stock (see Figures 26 & 27). This is a necessary step when preparing a workpiece to be run through a planer when squaring stock.

NOTICE If you are not experienced with a jointer, set the depth of cut to 0", and practice feeding the workpiece across the tables as described. This procedure will better pre- pare you for the actual operation.

Figure 26. Typical surface planing operation.

Figure 27. Illustration of surface planing results.

G0656 8" Jointer with |