Fence: Place one or two drops of light machine oil on the fence pivot points (Figure 48) as needed.

Figure 48. Fence lubrication locations.

Cleaning

Vacuum excess wood chips and sawdust, and wipe off the remaining dust with a dry

V-Belts

Consider replacing the stock belt with Power Twist

To adjust/replace the V-belt:

1.DISCONNECT JOINTER FROM POWER SOURCE!

2.Remove the rear access panel.

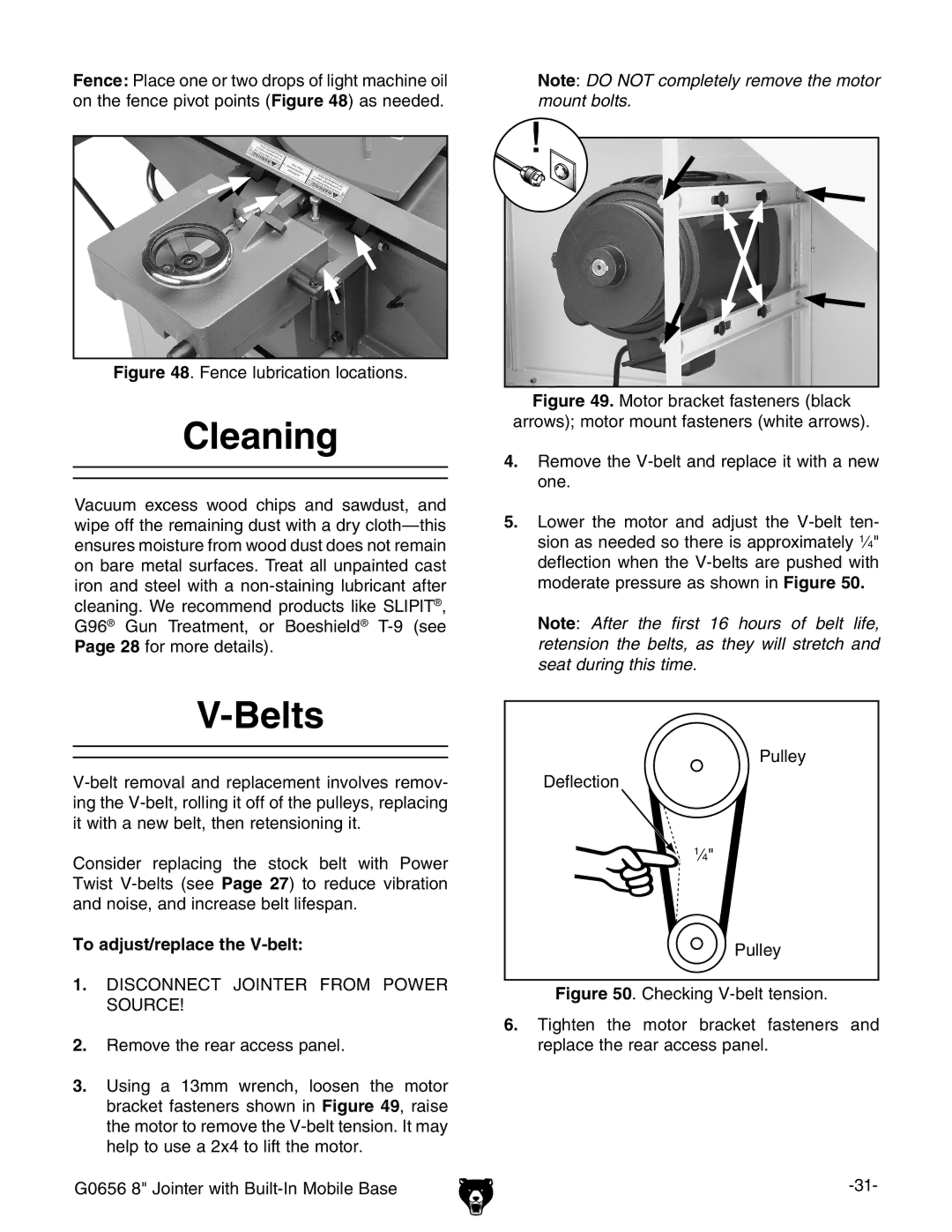

3.Using a 13mm wrench, loosen the motor bracket fasteners shown in Figure 49, raise the motor to remove the

G0656 8" Jointer with Built-In Mobile Base

Note: DO NOT completely remove the motor mount bolts.

Figure 49. Motor bracket fasteners (black

arrows); motor mount fasteners (white arrows).

4.Remove the V-belt and replace it with a new one.

5.Lower the motor and adjust the V-belt ten- sion as needed so there is approximately 1⁄4" deflection when the V-belts are pushed with moderate pressure as shown in Figure 50.

Note: After the first 16 hours of belt life, retension the belts, as they will stretch and seat during this time.

������

����������

1⁄4"

������