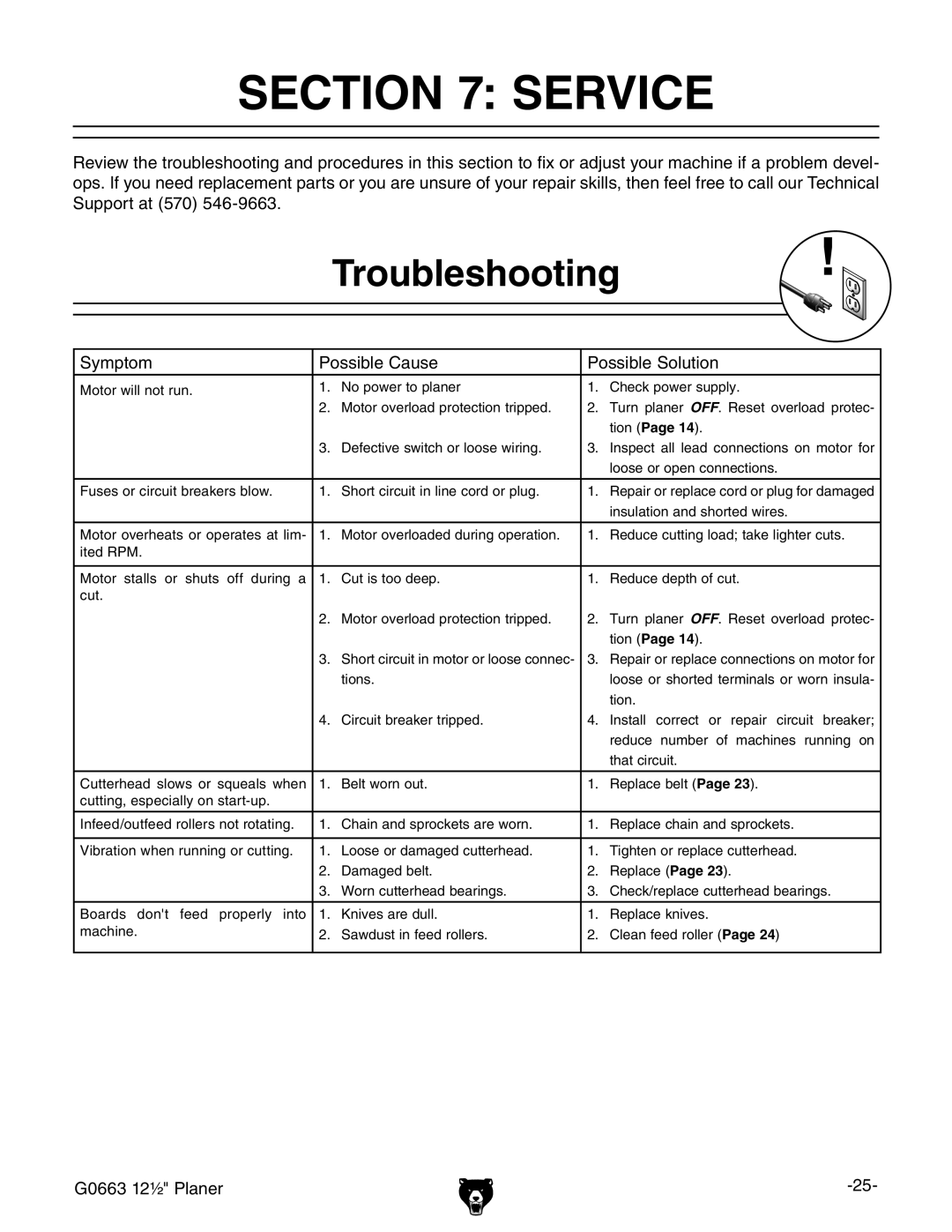

SECTION 7: SERVICE

Review the troubleshooting and procedures in this section to fix or adjust your machine if a problem devel- ops. If you need replacement parts or you are unsure of your repair skills, then feel free to call our Technical Support at (570)

Troubleshooting

Symptom | Possible Cause | Possible Solution | ||

|

|

|

|

|

Motor will not run. | 1. | No power to planer | 1. | Check power supply. |

| 2. | Motor overload protection tripped. | 2. | Turn planer OFF. Reset overload protec- |

|

|

|

| tion (Page 14). |

| 3. | Defective switch or loose wiring. | 3. | Inspect all lead connections on motor for |

|

|

|

| loose or open connections. |

|

|

|

|

|

Fuses or circuit breakers blow. | 1. | Short circuit in line cord or plug. | 1. | Repair or replace cord or plug for damaged |

|

|

|

| insulation and shorted wires. |

|

|

|

|

|

Motor overheats or operates at lim- | 1. | Motor overloaded during operation. | 1. | Reduce cutting load; take lighter cuts. |

ited RPM. |

|

|

|

|

|

|

|

|

|

Motor stalls or shuts off during a | 1. | Cut is too deep. | 1. | Reduce depth of cut. |

cut. |

|

|

|

|

| 2. | Motor overload protection tripped. | 2. | Turn planer OFF. Reset overload protec- |

|

|

|

| tion (Page 14). |

| 3. | Short circuit in motor or loose connec- | 3. Repair or replace connections on motor for | |

|

| tions. |

| loose or shorted terminals or worn insula- |

|

|

|

| tion. |

| 4. | Circuit breaker tripped. | 4. | Install correct or repair circuit breaker; |

|

|

|

| reduce number of machines running on |

|

|

|

| that circuit. |

|

|

|

|

|

Cutterhead slows or squeals when | 1. | Belt worn out. | 1. | Replace belt (Page 23). |

cutting, especially on |

|

|

|

|

|

|

|

|

|

Infeed/outfeed rollers not rotating. | 1. | Chain and sprockets are worn. | 1. | Replace chain and sprockets. |

|

|

|

|

|

Vibration when running or cutting. | 1. | Loose or damaged cutterhead. | 1. | Tighten or replace cutterhead. |

| 2. | Damaged belt. | 2. | Replace (Page 23). |

| 3. | Worn cutterhead bearings. | 3. | Check/replace cutterhead bearings. |

|

|

|

|

|

Boards don't feed properly into | 1. | Knives are dull. | 1. | Replace knives. |

machine. | 2. | Sawdust in feed rollers. | 2. | Clean feed roller (Page 24) |

|

|

|

|

|

G0663 12½" Planer |