Lubrication

Points requiring periodic lubrication are:

A.Column. A light film of oil (Mobil Vactra 2 or ISO 68 equivalent) will smooth action and prevent rust and corrosion.

B.Column Rack. Lubricate every 90 days with NLGI #2 grease.

C.Quill. A light coating of oil (Mobil Vactra 2) will ensure smooth movement.

D.Quill Rack. Lubricate every 90 days with NLGI #2 grease.

E.Table Leadscrews. Lubricate once each week with several drops of Mobil Vactra 2 or way oil. Refer to Table Leadscrews on this page for more information on this procedure.

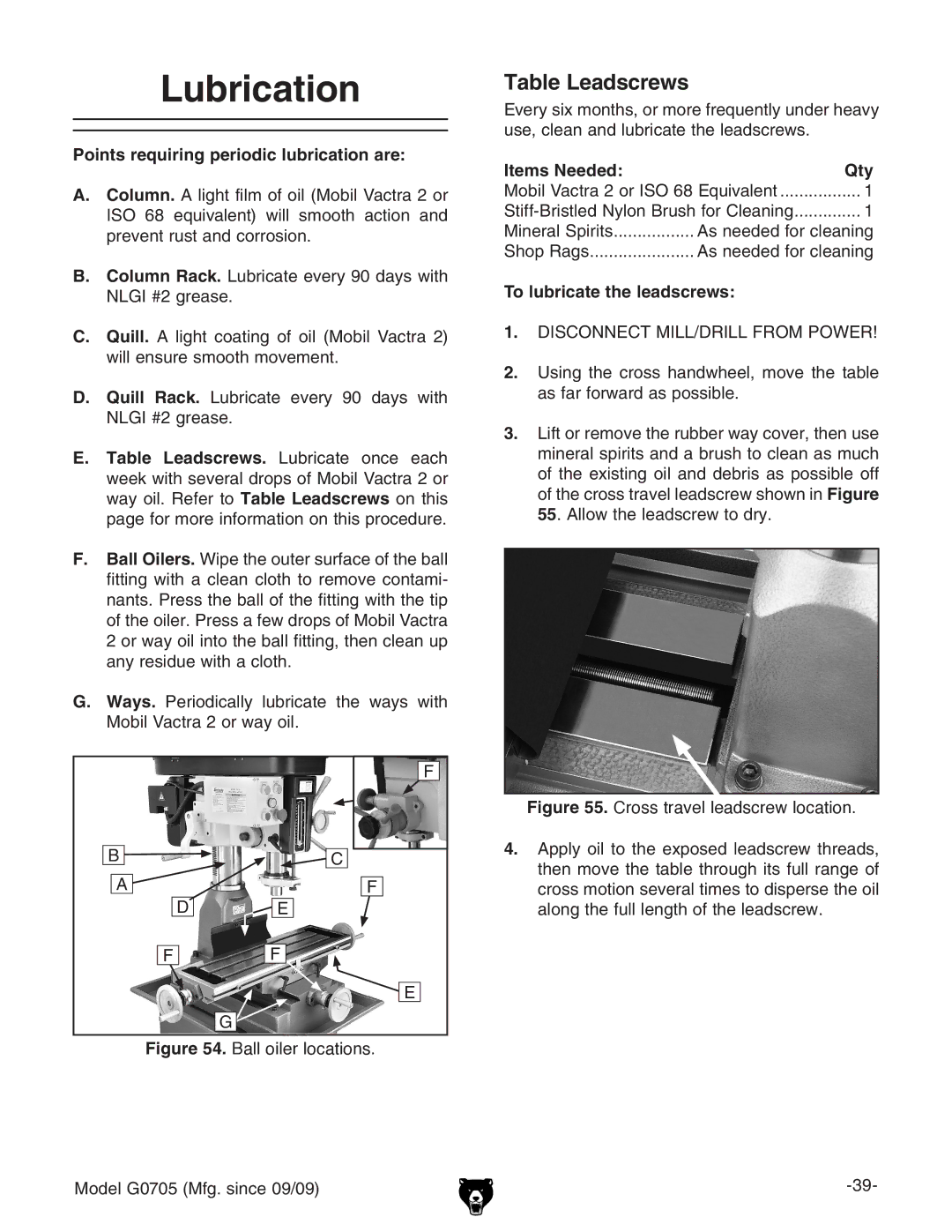

F.Ball Oilers. Wipe the outer surface of the ball fitting with a clean cloth to remove contami- nants. Press the ball of the fitting with the tip of the oiler. Press a few drops of Mobil Vactra 2 or way oil into the ball fitting, then clean up any residue with a cloth.

G.Ways. Periodically lubricate the ways with Mobil Vactra 2 or way oil.

F

B | C |

A | F |

D | E |

F | F |

| E |

| G |

Figure 54. Ball oiler locations.

Model G0705 (Mfg. since 09/09)

Table Leadscrews

Every six months, or more frequently under heavy use, clean and lubricate the leadscrews.

Items Needed: |

| Qty |

Mobil Vactra 2 or ISO 68 Equivalent | 1 | |

1 | ||

Mineral Spirits | As needed for cleaning | |

Shop Rags | As needed for cleaning | |

To lubricate the leadscrews:

1.DISCONNECT MILL/DRILL FROM POWER!

2.Using the cross handwheel, move the table as far forward as possible.

3.Lift or remove the rubber way cover, then use mineral spirits and a brush to clean as much of the existing oil and debris as possible off of the cross travel leadscrew shown in Figure 55. Allow the leadscrew to dry.