Headstock Travel

(Z-Axis and Rotation)

Headstock height is adjustable in the vertical

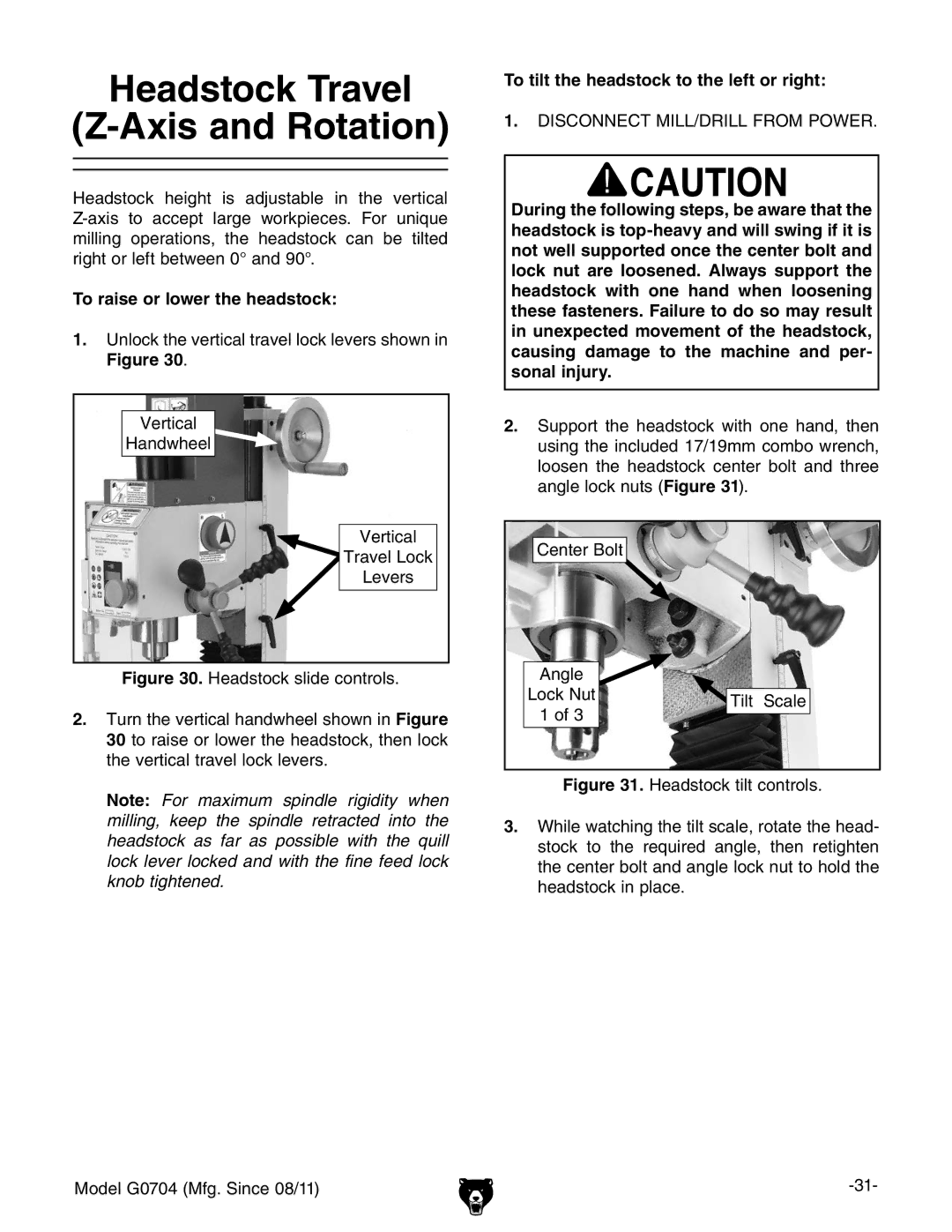

To raise or lower the headstock:

1.Unlock the vertical travel lock levers shown in Figure 30.

Vertical

Handwheel![]()

Vertical

Travel Lock

Levers

Figure 30. Headstock slide controls.

2.Turn the vertical handwheel shown in Figure 30 to raise or lower the headstock, then lock the vertical travel lock levers.

Note: For maximum spindle rigidity when milling, keep the spindle retracted into the headstock as far as possible with the quill lock lever locked and with the fine feed lock knob tightened.

Model G0704 (Mfg. Since 08/11)

To tilt the headstock to the left or right:

1.DISCONNECT MILL/DRILL FROM POWER.

During the following steps, be aware that the headstock is

2.Support the headstock with one hand, then using the included 17/19mm combo wrench, loosen the headstock center bolt and three angle lock nuts (Figure 31).

Center Bolt

Angle |

|

| |

Lock Nut |

|

| |

Tilt Scale | |||

1 of 3 |

| ||

|

| ||

| |||

|

|

|