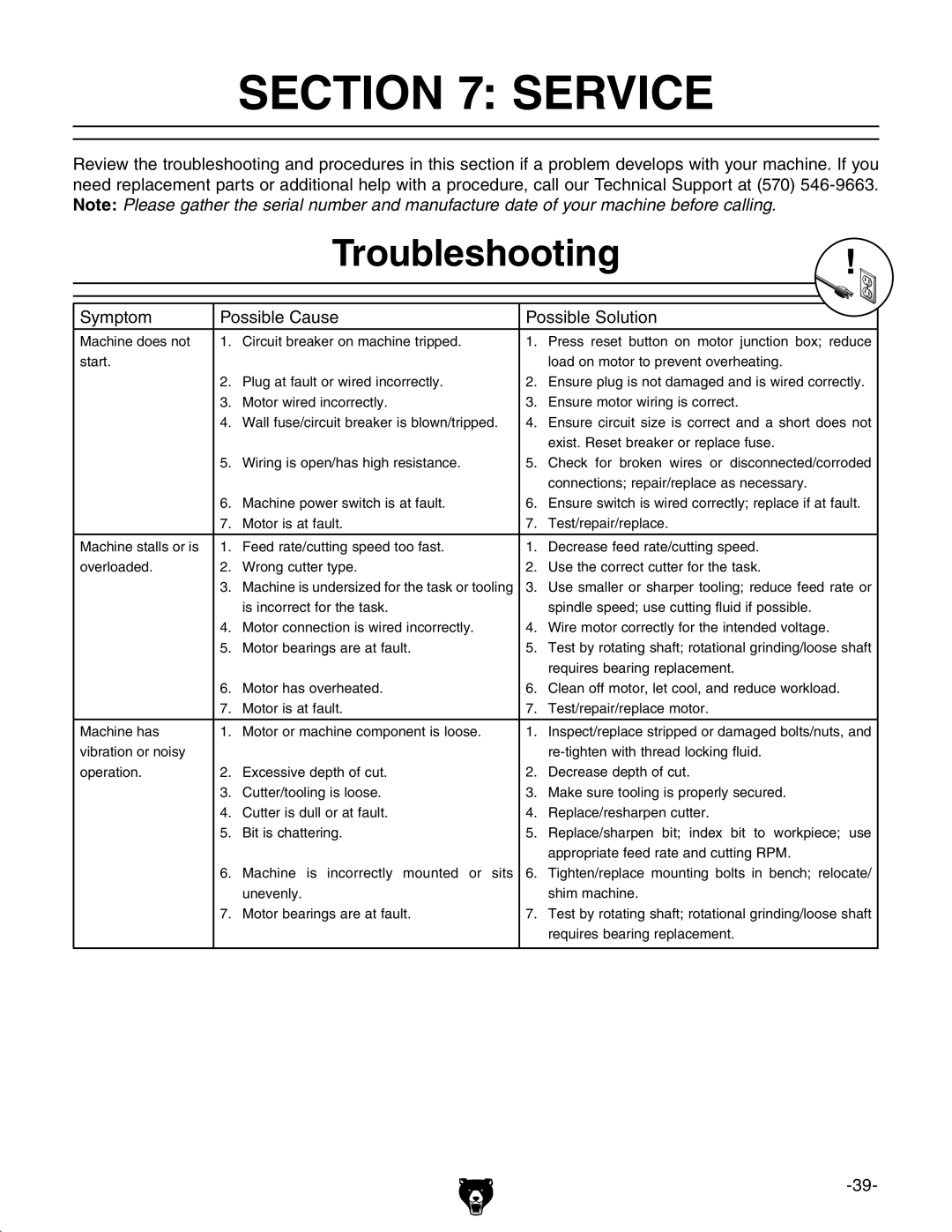

SECTION 7: SERVICE

Review the troubleshooting and procedures in this section if a problem develops with your machine. If you need replacement parts or additional help with a procedure, call our Technical Support at (570)

Troubleshooting

Symptom | Possible Cause | Possible Solution | ||

Machine does not | 1. | Circuit breaker on machine tripped. | 1. | Press reset button on motor junction box; reduce |

start. |

|

|

| load on motor to prevent overheating. |

| 2. | Plug at fault or wired incorrectly. | 2. | Ensure plug is not damaged and is wired correctly. |

| 3. | Motor wired incorrectly. | 3. | Ensure motor wiring is correct. |

| 4. | Wall fuse/circuit breaker is blown/tripped. | 4. | Ensure circuit size is correct and a short does not |

|

|

|

| exist. Reset breaker or replace fuse. |

| 5. | Wiring is open/has high resistance. | 5. | Check for broken wires or disconnected/corroded |

|

|

|

| connections; repair/replace as necessary. |

| 6. | Machine power switch is at fault. | 6. | Ensure switch is wired correctly; replace if at fault. |

| 7. | Motor is at fault. | 7. | Test/repair/replace. |

|

|

|

|

|

Machine stalls or is | 1. | Feed rate/cutting speed too fast. | 1. | Decrease feed rate/cutting speed. |

overloaded. | 2. | Wrong cutter type. | 2. | Use the correct cutter for the task. |

| 3. | Machine is undersized for the task or tooling | 3. | Use smaller or sharper tooling; reduce feed rate or |

|

| is incorrect for the task. |

| spindle speed; use cutting fluid if possible. |

| 4. | Motor connection is wired incorrectly. | 4. | Wire motor correctly for the intended voltage. |

| 5. | Motor bearings are at fault. | 5. | Test by rotating shaft; rotational grinding/loose shaft |

|

|

|

| requires bearing replacement. |

| 6. | Motor has overheated. | 6. | Clean off motor, let cool, and reduce workload. |

| 7. | Motor is at fault. | 7. | Test/repair/replace motor. |

|

|

|

|

|

Machine has | 1. | Motor or machine component is loose. | 1. | Inspect/replace stripped or damaged bolts/nuts, and |

vibration or noisy |

|

|

| |

operation. | 2. | Excessive depth of cut. | 2. | Decrease depth of cut. |

| 3. | Cutter/tooling is loose. | 3. | Make sure tooling is properly secured. |

| 4. | Cutter is dull or at fault. | 4. | Replace/resharpen cutter. |

| 5. | Bit is chattering. | 5. | Replace/sharpen bit; index bit to workpiece; use |

|

|

|

| appropriate feed rate and cutting RPM. |

| 6. | machine is incorrectly mounted or sits | 6. | Tighten/replace mounting bolts in bench; relocate/ |

|

| unevenly. |

| shim machine. |

| 7. | Motor bearings are at fault. | 7. | Test by rotating shaft; rotational grinding/loose shaft |

|

|

|

| requires bearing replacement. |

|

|

|

|

|

Model G0704 (Mfg. Since 08/11) |