SECTION 6: MAINTENANCE

Always disconnect power to the machine before performing maintenance. Failure to do this may result in serious person- al injury.

Schedule

For optimum performance from your machine, follow this maintenance schedule and refer to any specific instructions given in this section.

Daily Check:

•make sure mill/drill is disconnected from power when not in use.

•Check for loose mounting bolts.

•Make sure mill/drill is clean and lubricated.

•Check for worn or damaged wires.

•Check for any other unsafe condition.

Monthly Check:

•Check that gibs are adjusted properly.

Biannual Check:

•Lubricate headstock lead screw and gears.

Lubrication

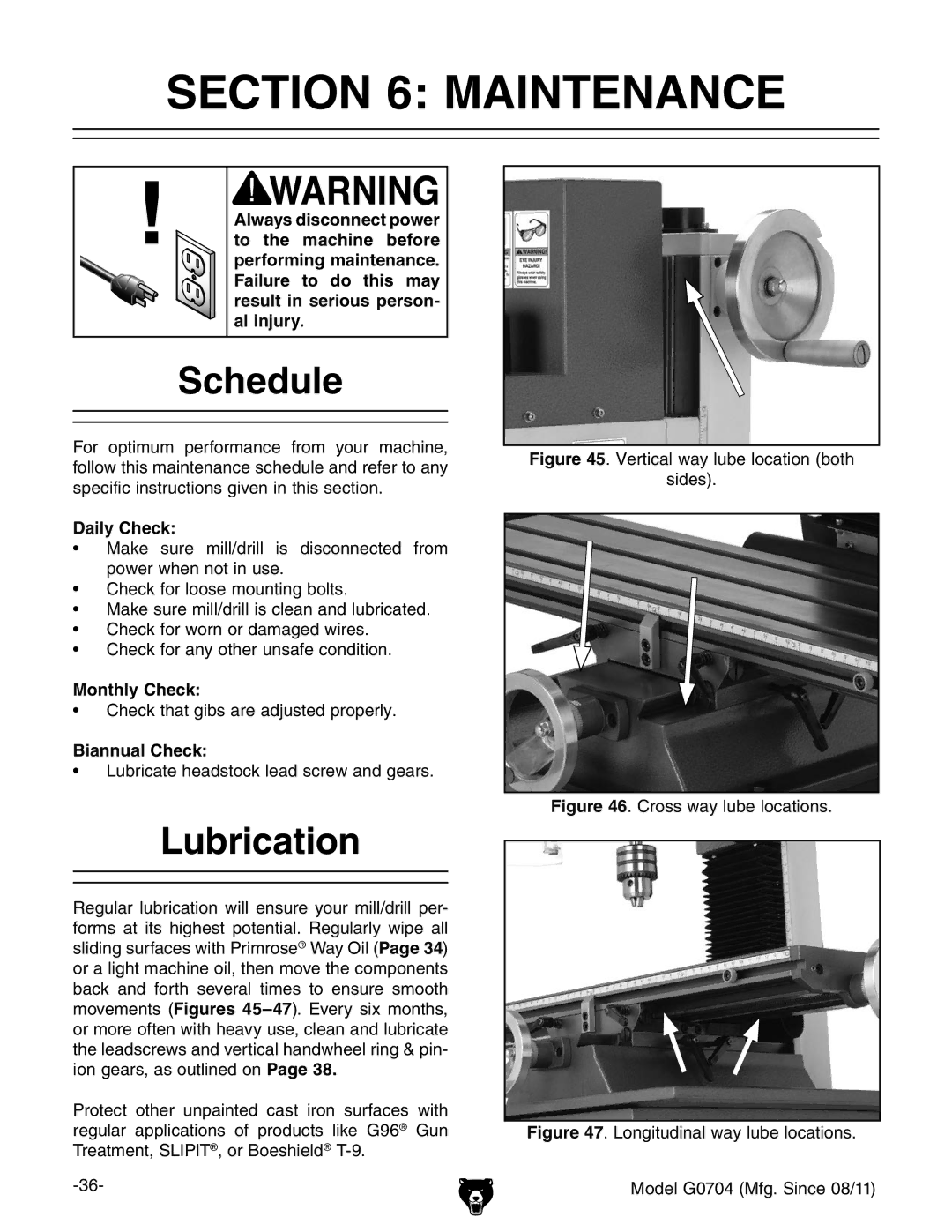

Regular lubrication will ensure your mill/drill per- forms at its highest potential. Regularly wipe all sliding surfaces with Primrose® Way Oil (Page 34) or a light machine oil, then move the components back and forth several times to ensure smooth movements (Figures

Protect other unpainted cast iron surfaces with regular applications of products like G96® Gun Treatment, SLipit®, or Boeshield®