6.Assemble ball bearing segments into two strips of equal size (four segments each).

7.Apply medium coat of NLGI#2 grease to ball bearing strips.

8.Position ball bearing strips in middle of sad- dle ways, as shown in Figure 16.

Ball Bearing Strips

Figure 16. Ball bearing strips positioned on

saddle ways.

9.With the help of another person, gently place table right side up on ball bearing strips.

10.Feed table cable under table so that attached cable barrel is on the right of machine, as shown in Figure 17.

![]() x 1

x 1

Cable Barrel

Figure 17. Cable barrel attached.

11.Secure barrel to table with (1) M10-1.5 x 50 cap screw.

Model G0763 (Mfg. Since 8/13)

Note: When cable is properly wrapped around pulley in next step, have another person maintain enough tension on cable so that it stays in pulley grooves until it can be secured in following steps.

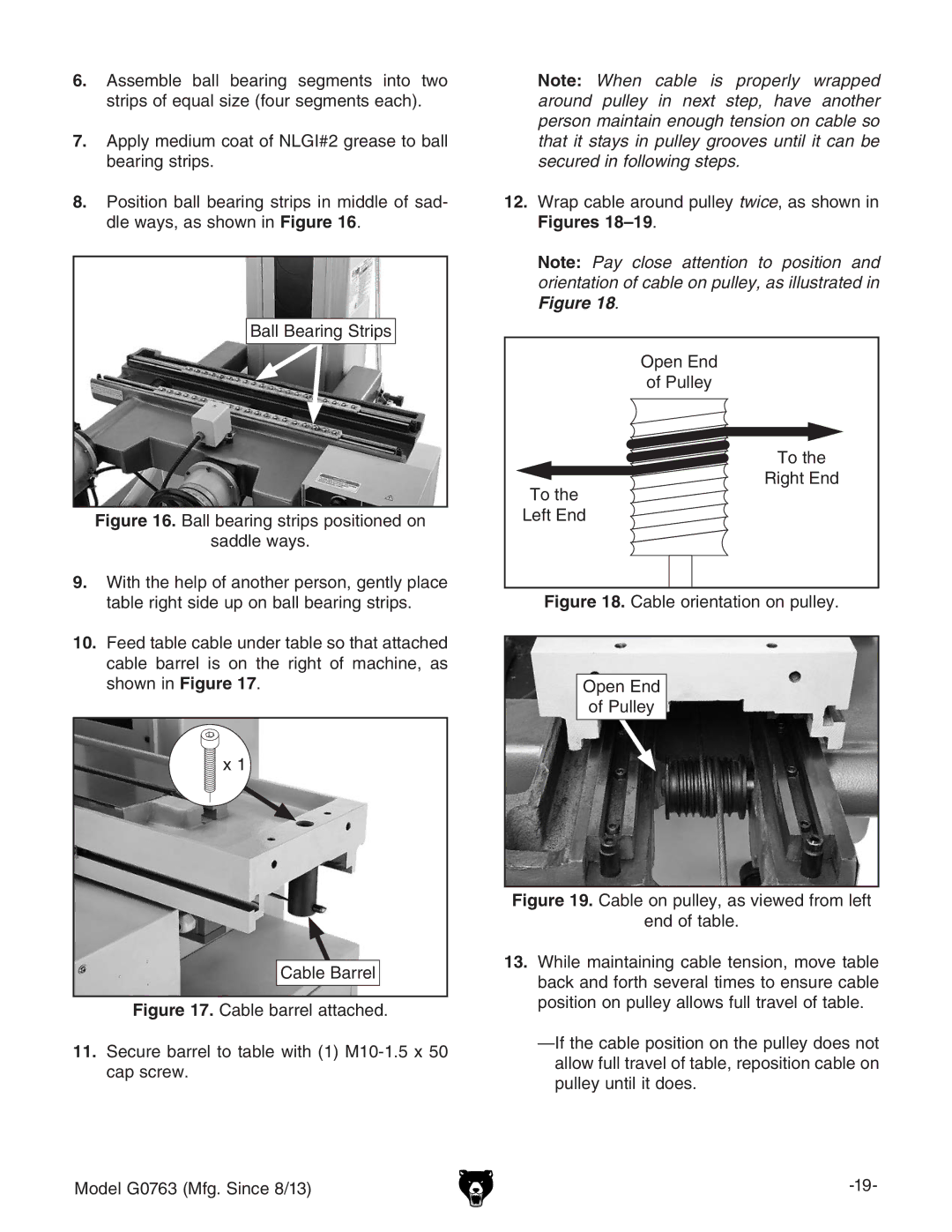

12.Wrap cable around pulley twice, as shown in Figures 18–19.

Note: Pay close attention to position and orientation of cable on pulley, as illustrated in Figure 18.

Open End |

of Pulley |

To the |

Right End |

To the |

Left End |