Table Ball Bearing Strips

Type | T23964 or NLGI#2 Equivalent | |

Amount | As Needed | |

Lubrication Frequency | ..............................Monthly | |

To lubricate table ball bearing strips:

1.DISCONNECT MACHINE FROM POWER!

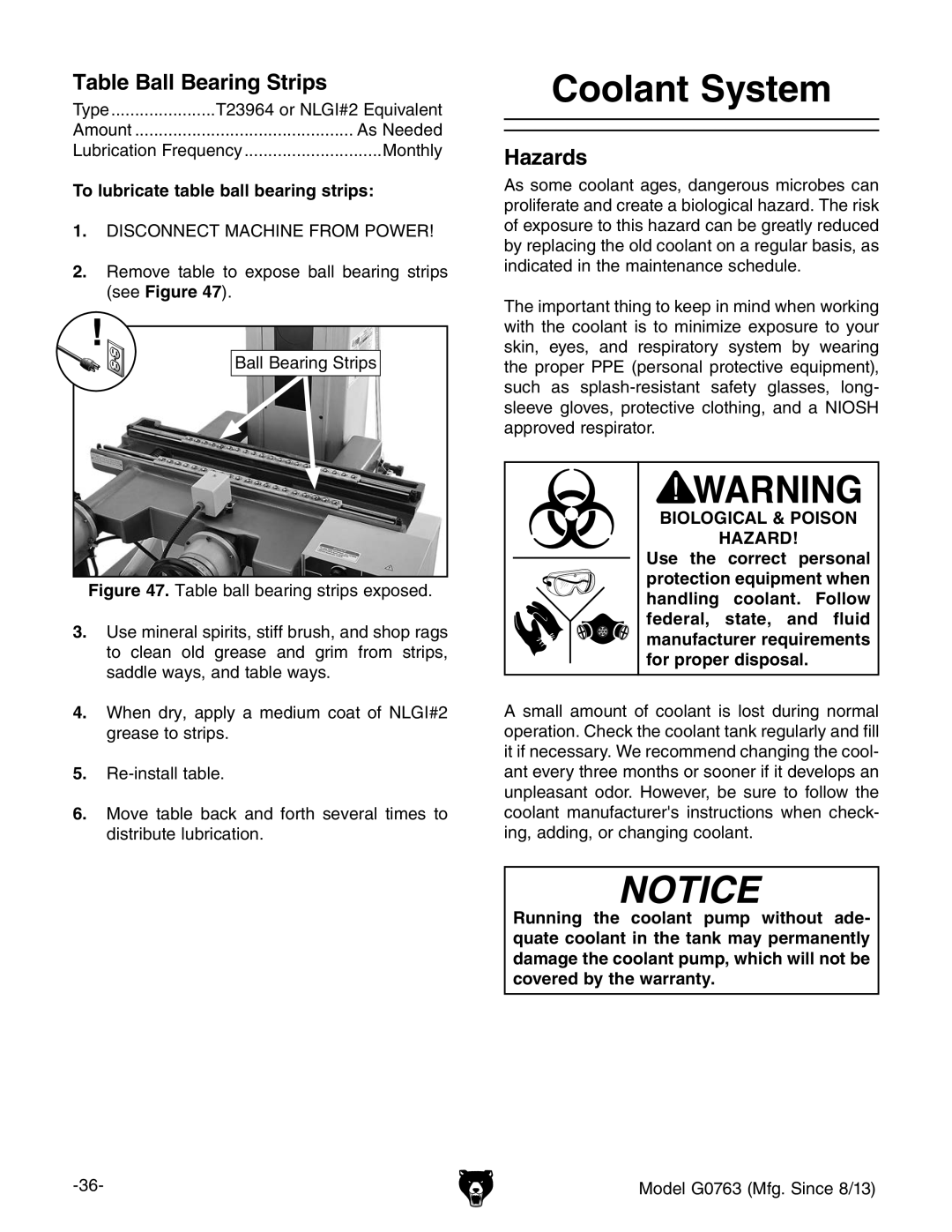

2.Remove table to expose ball bearing strips (see Figure 47).

Ball Bearing Strips

Figure 47. Table ball bearing strips exposed.

3.Use mineral spirits, stiff brush, and shop rags to clean old grease and grim from strips, saddle ways, and table ways.

4.When dry, apply a medium coat of NLGI#2 grease to strips.

5.Re-install table.

6.Move table back and forth several times to distribute lubrication.

Coolant System

Hazards

As some coolant ages, dangerous microbes can proliferate and create a biological hazard. The risk of exposure to this hazard can be greatly reduced by replacing the old coolant on a regular basis, as indicated in the maintenance schedule.

The important thing to keep in mind when working with the coolant is to minimize exposure to your skin, eyes, and respiratory system by wearing the proper PPE (personal protective equipment), such as

BIOLOGICAL & POISON

HAZARD!

Use the correct personal protection equipment when handling coolant. Follow federal, state, and fluid manufacturer requirements for proper disposal.

A small amount of coolant is lost during normal operation. Check the coolant tank regularly and fill it if necessary. We recommend changing the cool- ant every three months or sooner if it develops an unpleasant odor. However, be sure to follow the coolant manufacturer's instructions when check- ing, adding, or changing coolant.

Running the coolant pump without ade- quate coolant in the tank may permanently damage the coolant pump, which will not be covered by the warranty.