Lubrication

Other than the lubrication points covered in this section, all other bearings are internally lubricated and sealed at the factory. Simply leave them alone unless they need to be replaced.

One-Shot Oiler

Type | Model T23963 or ISO 32 Equivalent | |

Amount | ||

Lubrication Frequency | ||

The

To use the

Fill

Cap![]()

Sight

![]() Glass

Glass

Pump

Handle

Figure 45. One-shot oiler components.

Use the sight glass to check the oil level and fill when needed.

Model G0763 (Mfg. Since 8/13)

Oil Sump

As the

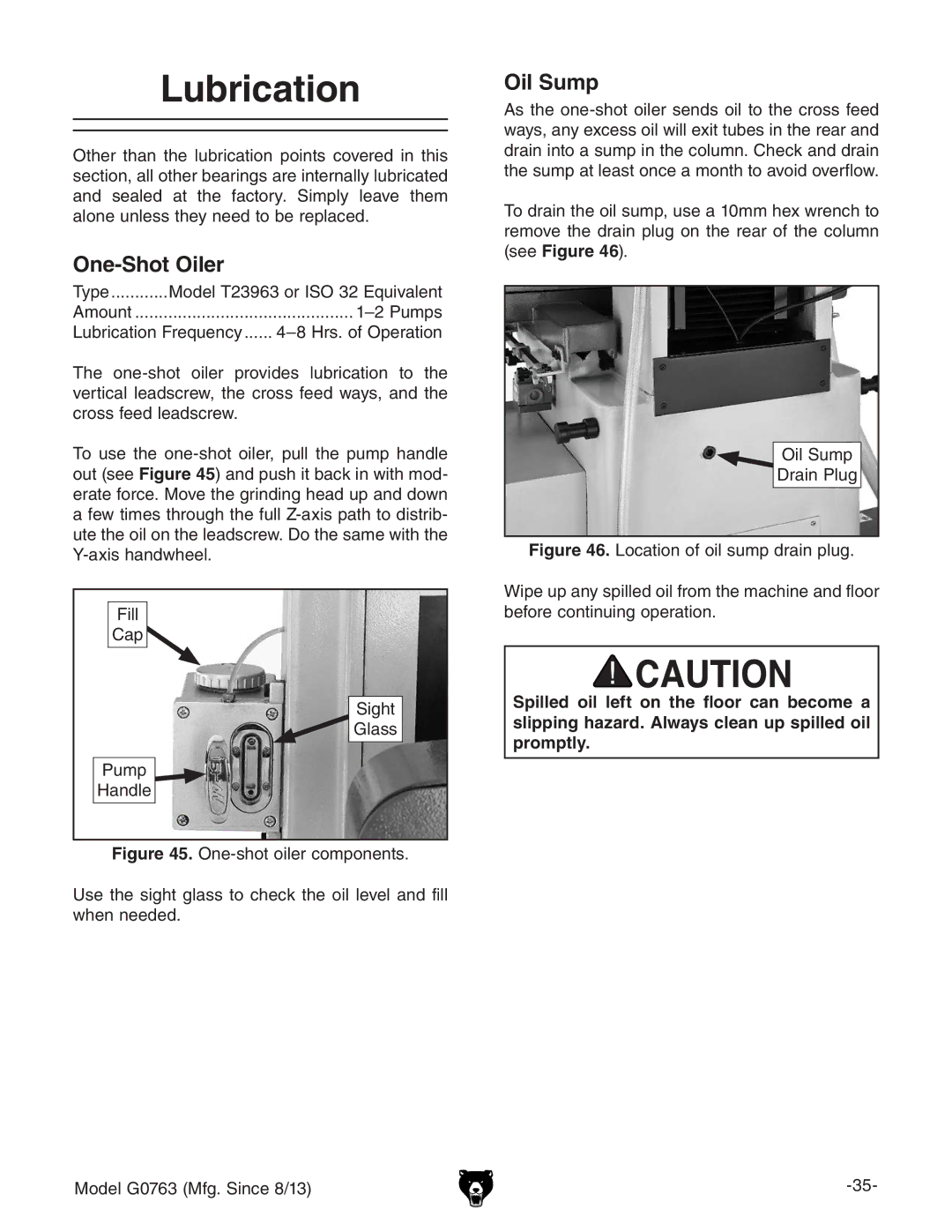

To drain the oil sump, use a 10mm hex wrench to remove the drain plug on the rear of the column (see Figure 46).

Oil Sump

Drain Plug

Figure 46. Location of oil sump drain plug.

Wipe up any spilled oil from the machine and floor before continuing operation.

Spilled oil left on the floor can become a slipping hazard. Always clean up spilled oil promptly.