SECTION 6: OPERATIONS

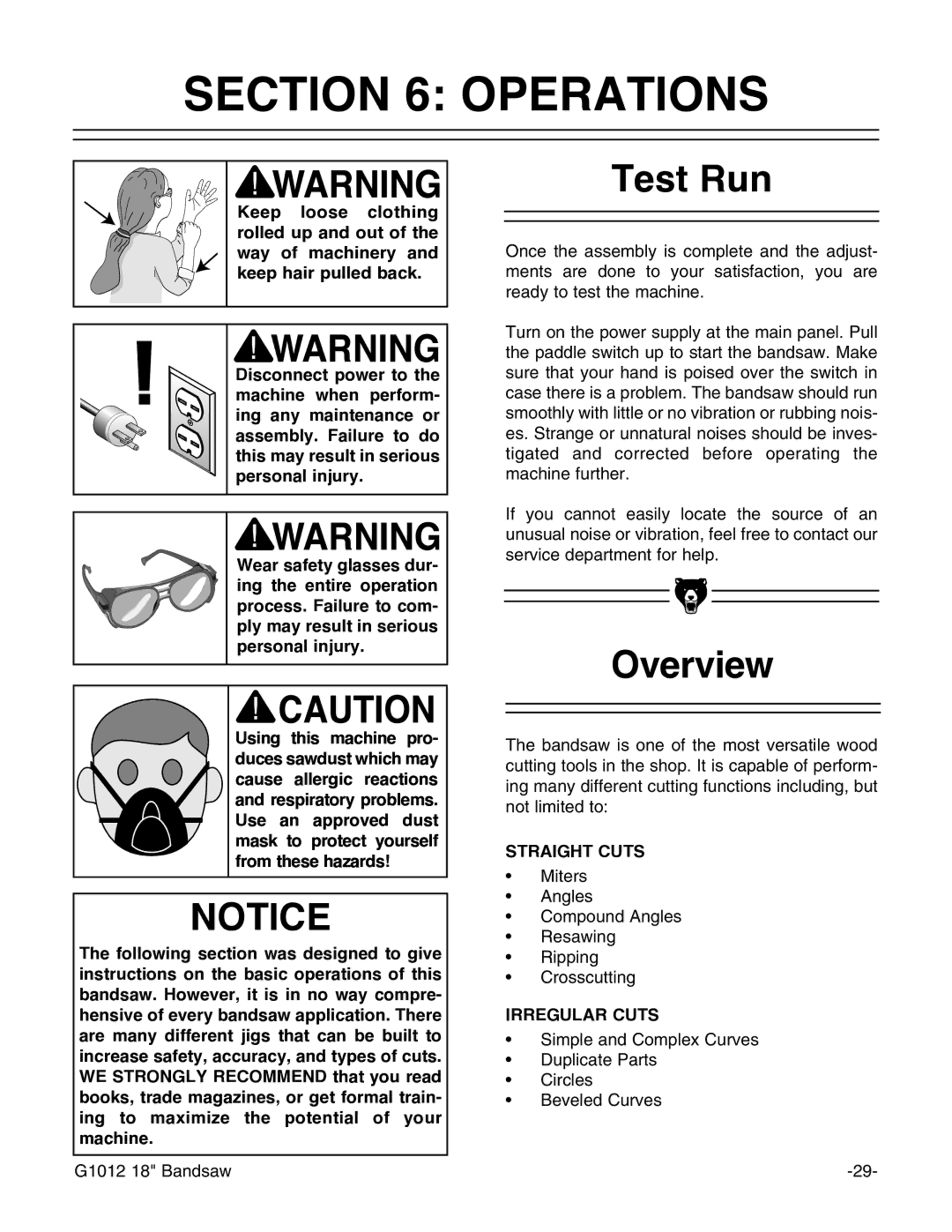

Keep loose clothing rolled up and out of the way of machinery and keep hair pulled back.

Disconnect power to the machine when perform- ing any maintenance or assembly. Failure to do this may result in serious personal injury.

Wear safety glasses dur- ing the entire operation process. Failure to com- ply may result in serious personal injury.

Using this machine pro- duces sawdust which may cause allergic reactions and respiratory problems. Use an approved dust mask to protect yourself from these hazards!

NOTICE

The following section was designed to give instructions on the basic operations of this bandsaw. However, it is in no way compre- hensive of every bandsaw application. There are many different jigs that can be built to increase safety, accuracy, and types of cuts. WE STRONGLY RECOMMEND that you read books, trade magazines, or get formal train- ing to maximize the potential of your machine.

G1012 18" Bandsaw

Test Run

Once the assembly is complete and the adjust- ments are done to your satisfaction, you are ready to test the machine.

Turn on the power supply at the main panel. Pull the paddle switch up to start the bandsaw. Make sure that your hand is poised over the switch in case there is a problem. The bandsaw should run smoothly with little or no vibration or rubbing nois- es. Strange or unnatural noises should be inves- tigated and corrected before operating the machine further.

If you cannot easily locate the source of an unusual noise or vibration, feel free to contact our service department for help.

Overview

The bandsaw is one of the most versatile wood cutting tools in the shop. It is capable of perform- ing many different cutting functions including, but not limited to:

STRAIGHT CUTS

•Miters

•Angles

•Compound Angles

•Resawing

•Ripping

•Crosscutting

IRREGULAR CUTS

•Simple and Complex Curves

•Duplicate Parts

•Circles

•Beveled Curves