Site Considerations

Workbench Load

Refer to the Machine Data Sheet for the weight and footprint specifications of your machine. Some floors may require additional reinforcement to support both the machine, the workbench and the workpiece.

Placement Location

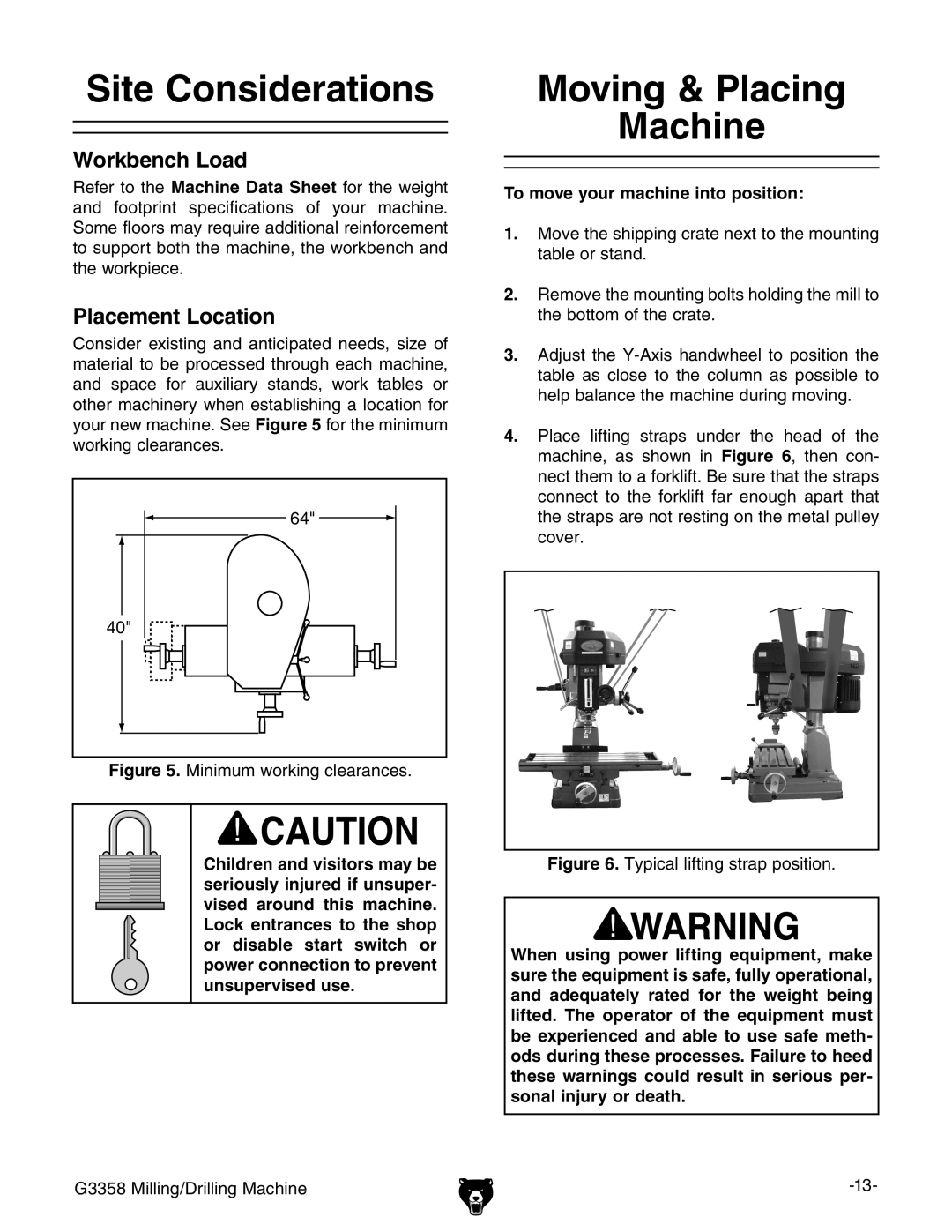

Consider existing and anticipated needs, size of material to be processed through each machine, and space for auxiliary stands, work tables or other machinery when establishing a location for your new machine. See Figure 5 for the minimum working clearances.

64"

40"

Figure 5. Minimum working clearances.

Children and visitors may be seriously injured if unsuper- vised around this machine. Lock entrances to the shop or disable start switch or power connection to prevent unsupervised use.

Moving & Placing

Machine

To move your machine into position:

1.Move the shipping crate next to the mounting table or stand.

2.Remove the mounting bolts holding the mill to the bottom of the crate.

3.Adjust the

4.Place lifting straps under the head of the machine, as shown in Figure 6, then con- nect them to a forklift. Be sure that the straps connect to the forklift far enough apart that the straps are not resting on the metal pulley cover.

Figure 6. Typical lifting strap position.

When using power lifting equipment, make sure the equipment is safe, fully operational, and adequately rated for the weight being lifted. The operator of the equipment must be experienced and able to use safe meth- ods during these processes. Failure to heed these warnings could result in serious per- sonal injury or death.

G3358 Milling/Drilling Machine |