Tighten the two head locking nuts.

Headstock Height

The headstock height on the Model G3358 can be adjusted for various applications. For best results during milling, keep the headstock fully retracted and set the headstock as low as possible.

To adjust the headstock height:

1. Using the lug wrench provided, loosen the two headstock locking nuts located on the right side of the head near the back (Figure 24).

Figure 24. Headstock locking nuts.

2. Use the head crank to move the head up or down according to your needs.

Depth Stop

The depth stop is used to limit the range of down- ward movement by the drill bit or cutter. Maximum depth is 5".

To calibrate the depth stop:

1.Install the cutting tool, then make sure the spindle is drawn all the way up into the head. To prevent damaging the workpiece, place a piece of paper on the workpiece. Loosen the headstock locking nuts and lower the head until the drill bit or cutter just contacts the paper. Tighten the headstock locking nuts. (Refer to Figure 24 for the location of the headstock locking nuts).

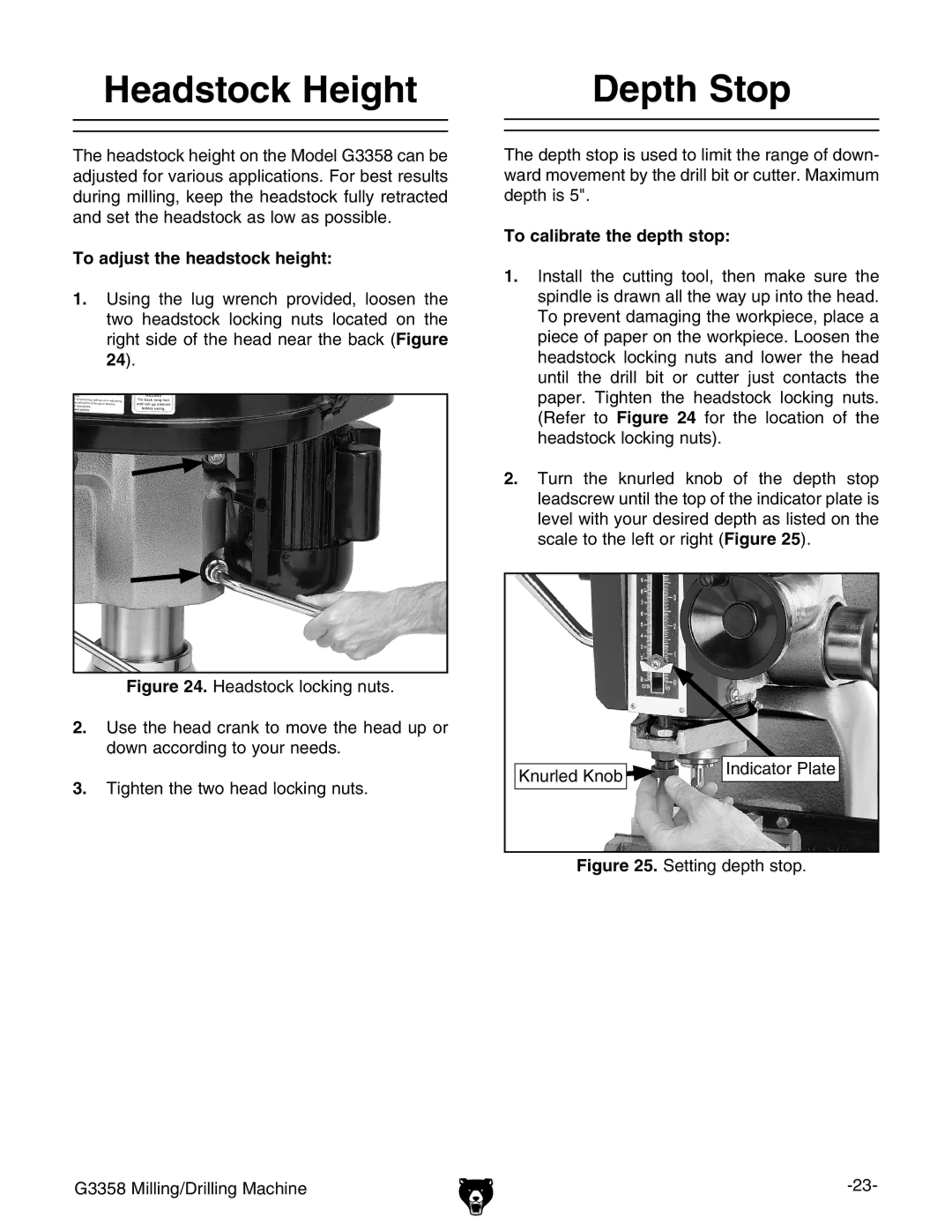

2.Turn the knurled knob of the depth stop leadscrew until the top of the indicator plate is level with your desired depth as listed on the scale to the left or right (Figure 25).

3.

Knurled Knob | Indicator Plate |

|

Figure 25. Setting depth stop.

G3358 Milling/Drilling Machine |