Cutting Speeds for High Speed Steel (HSS)

Cutting Tools

Workpiece Material | Cutting Speed (sfm) |

|

|

Aluminum & alloys | 300 |

|

|

Brass & Bronze | 150 |

|

|

Copper | 100 |

|

|

Cast Iron, soft | 80 |

|

|

Cast Iron, hard | 50 |

|

|

Mild Steel | 90 |

|

|

Cast Steel | 80 |

|

|

Alloy Steel, hard | 40 |

|

|

Tool Steel | 50 |

|

|

Stainless Steel | 60 |

|

|

Titanium | 50 |

|

|

Plastics | |

|

|

Wood | |

|

|

Note: For carbide cutting tools, double the cut- ting speed. These values are a guideline only. Refer to the MACHINERY'S HANDBOOK for more detailed information.

Figure 29. Cutting speed table for HSS cutting

tools.

Failure to follow RPM and feed rate guide- lines may threaten operator and bystander safety from ejected parts or broken tools.

NOTICE

Failure to follow RPM and feed rate guide- lines will put undue strain on moving parts, shorten tool life, and create poor workpiece results.

G3358 Milling/Drilling Machine

Graduated Dials

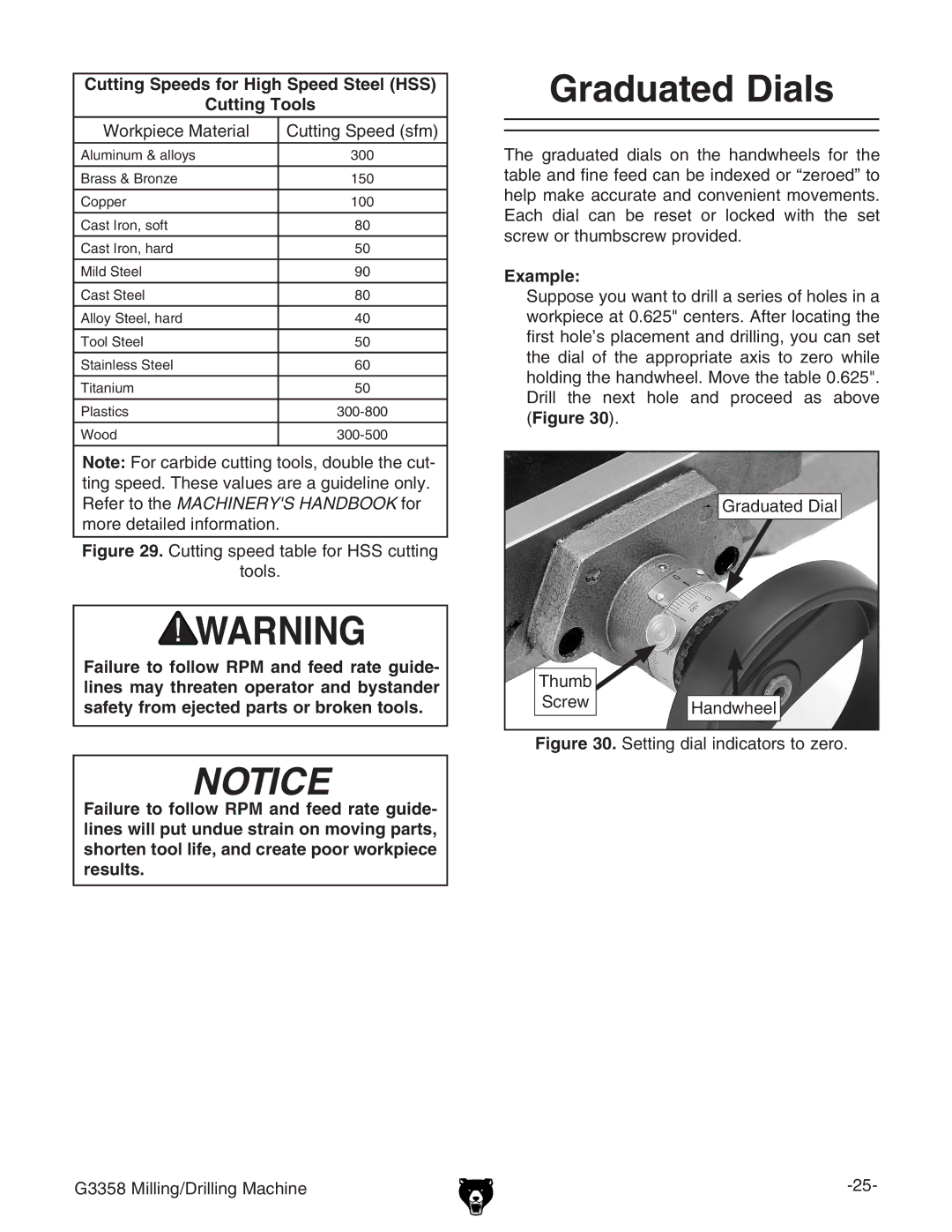

The graduated dials on the handwheels for the table and fine feed can be indexed or “zeroed” to help make accurate and convenient movements. Each dial can be reset or locked with the set screw or thumbscrew provided.

Example:

Suppose you want to drill a series of holes in a workpiece at 0.625" centers. After locating the first hole’s placement and drilling, you can set the dial of the appropriate axis to zero while holding the handwheel. Move the table 0.625". Drill the next hole and proceed as above (Figure 30).

Graduated Dial

Thumb |

|

Screw | Handwheel |

|