LubricationV-Belts

Points requiring periodic lubrication are:

•The main column. A light film of oil (SAE

30)will smooth action and prevent rust and corrosion.

•The quill. A light coating of oil (SAE 30) will ensure smooth movement.

•The quill pinion. Lubricate every 90 days with

•The table leadscrews. Lubricate once each week with several drops of SAE 30.

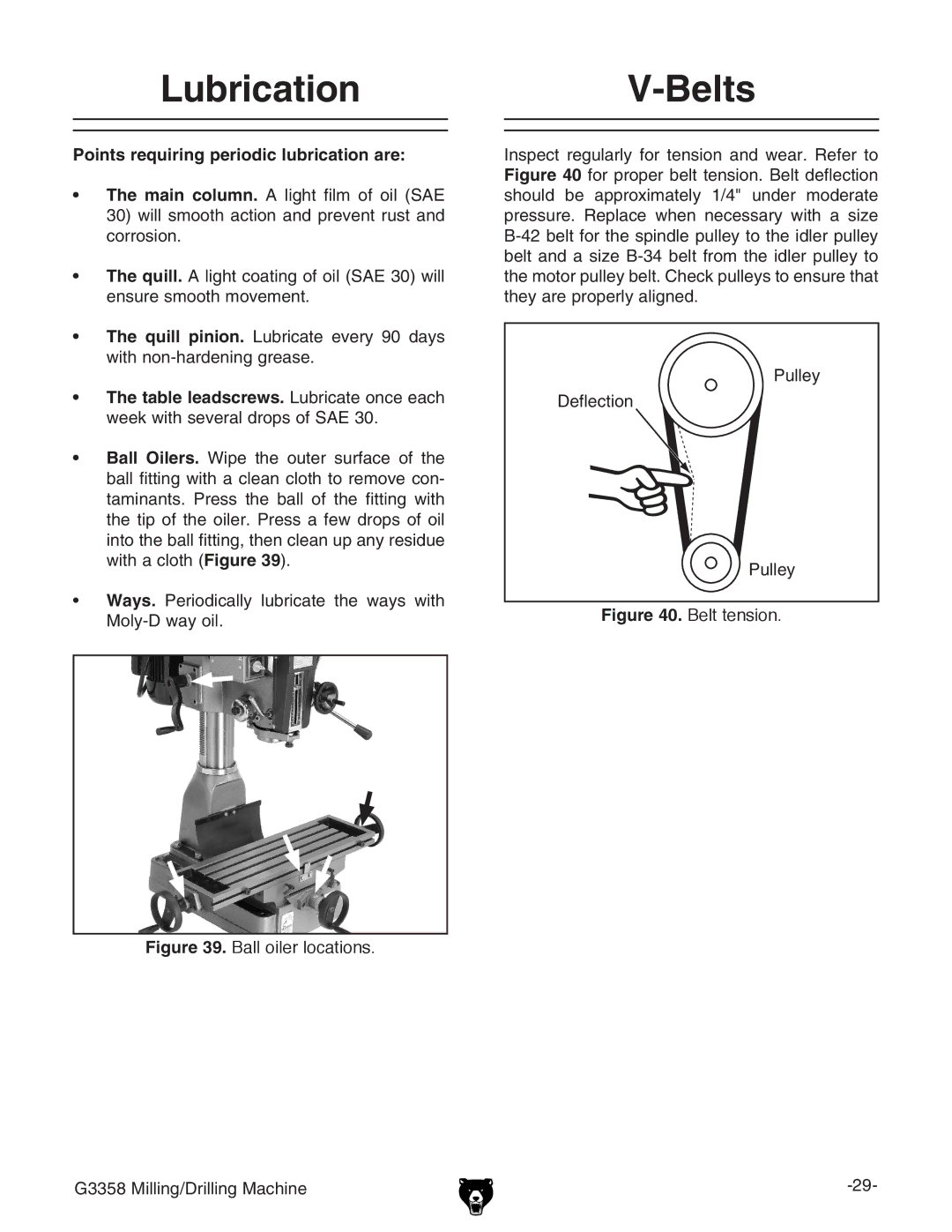

•Ball Oilers. Wipe the outer surface of the ball fitting with a clean cloth to remove con- taminants. Press the ball of the fitting with the tip of the oiler. Press a few drops of oil into the ball fitting, then clean up any residue with a cloth (Figure 39).

•Ways. Periodically lubricate the ways with

Figure 39. Ball oiler locations.

G3358 Milling/Drilling Machine

Inspect regularly for tension and wear. Refer to Figure 40 for proper belt tension. Belt deflection should be approximately 1/4" under moderate pressure. Replace when necessary with a size B-42 belt for the spindle pulley to the idler pulley belt and a size B-34 belt from the idler pulley to the motor pulley belt. Check pulleys to ensure that they are properly aligned.

EjaaZn

9Z[aZXi^dc

EjaaZn