7.Position the knife setting gauge on the out- feed table so that it extends over the cutter- head as shown in Figure 36, and loosen the gib bolts until the knife is completely loose.

Knife Setting |

Gauge |

Knife Edge At |

Highest Point |

Of Rotation |

Outfeed Table |

Figure 36. Checking knife with the

knife setting gauge.

8.Rock the cutterhead back-and-forth, using the cutterhead pulley to position the knife edge at the highest point in its revolution.

9.Using a 3mm allen wrench, find the jack screws through the access holes in the cut- terhead and rotate the jack screws to raise or lower the knife. When the knife is set correct- ly, it will barely touch bottom of the knife set- ting gauge WITHOUT lifting the gauge off the outfeed table. Note—The knife height should be level with the outfeed table to within .002". A dial indicator can be used to check varia- tion in thousandths of an inch; however, the knife setting gauge is an adequate setup instrument.

10.Snug the gib bolts tight enough to just hold the knife in place.

11.Repeat steps 5-10 with the rest of the knives.

12.Repeat step 10, but final tighten each gib bolt.

Ultimate Series Jointers

Carbide Cutters

(Models G9953ZX, G9953ZXF and G4815)

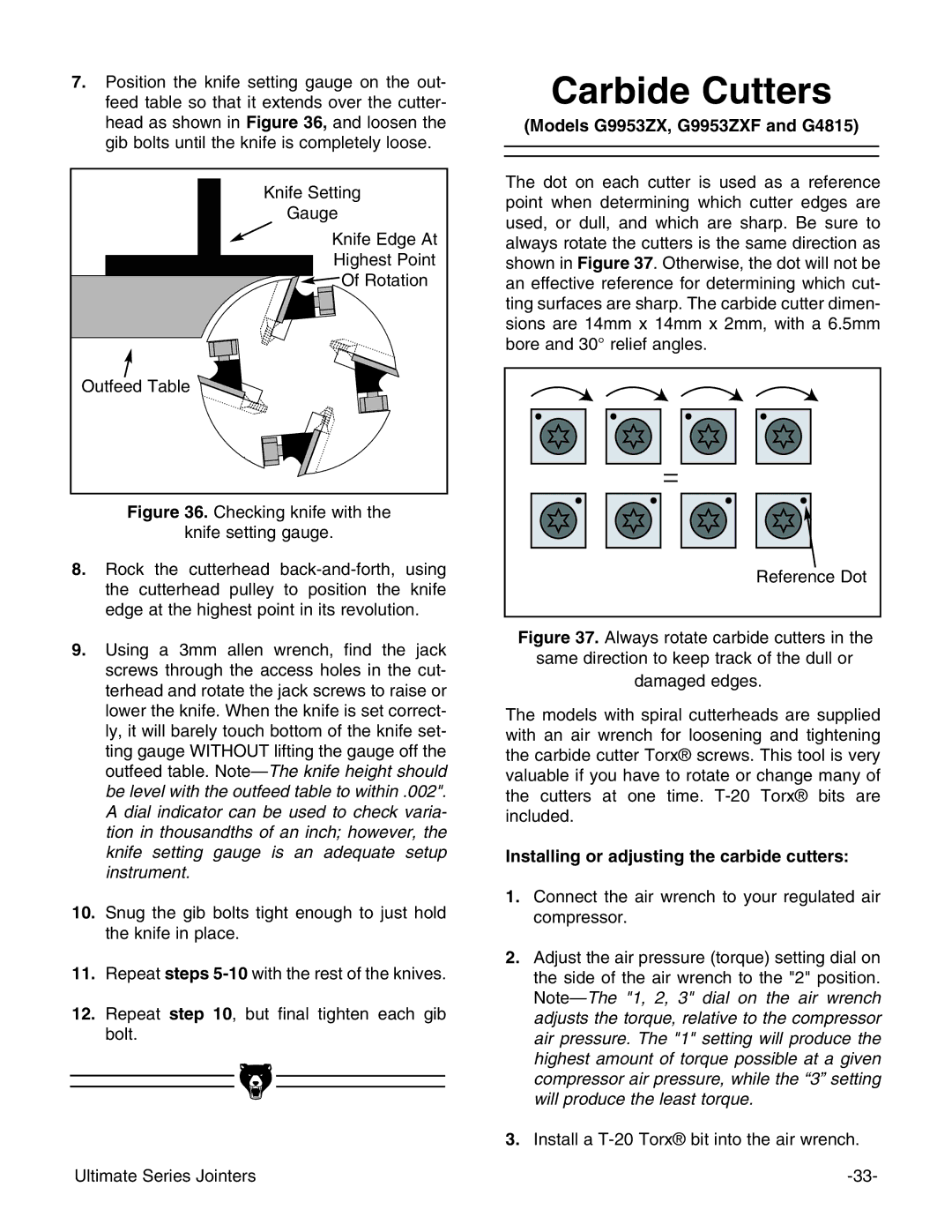

The dot on each cutter is used as a reference point when determining which cutter edges are used, or dull, and which are sharp. Be sure to always rotate the cutters is the same direction as shown in Figure 37. Otherwise, the dot will not be an effective reference for determining which cut- ting surfaces are sharp. The carbide cutter dimen- sions are 14mm x 14mm x 2mm, with a 6.5mm bore and 30° relief angles.

Reference Dot

Figure 37. Always rotate carbide cutters in the same direction to keep track of the dull or damaged edges.

The models with spiral cutterheads are supplied with an air wrench for loosening and tightening the carbide cutter Torx® screws. This tool is very valuable if you have to rotate or change many of the cutters at one time. T-20 Torx® bits are included.

Installing or adjusting the carbide cutters:

1.Connect the air wrench to your regulated air compressor.

2.Adjust the air pressure (torque) setting dial on the side of the air wrench to the "2" position.

3.Install a