•Remove foreign objects from the stock. Make sure that any stock you process with the jointer is clean and free of any dirt, nails, staples, tiny rocks or any other foreign objects that may damage the jointer blades.

•Only process natural wood fiber through your jointer. Never joint MDF, particle board, plywood, laminates or other syntheti- cally made materials.

•Make sure all stock is sufficiently dried before jointing. Wood with a moisture con- tent over 20% will cause unnecessary wear on the knives and will produce undesirable results.

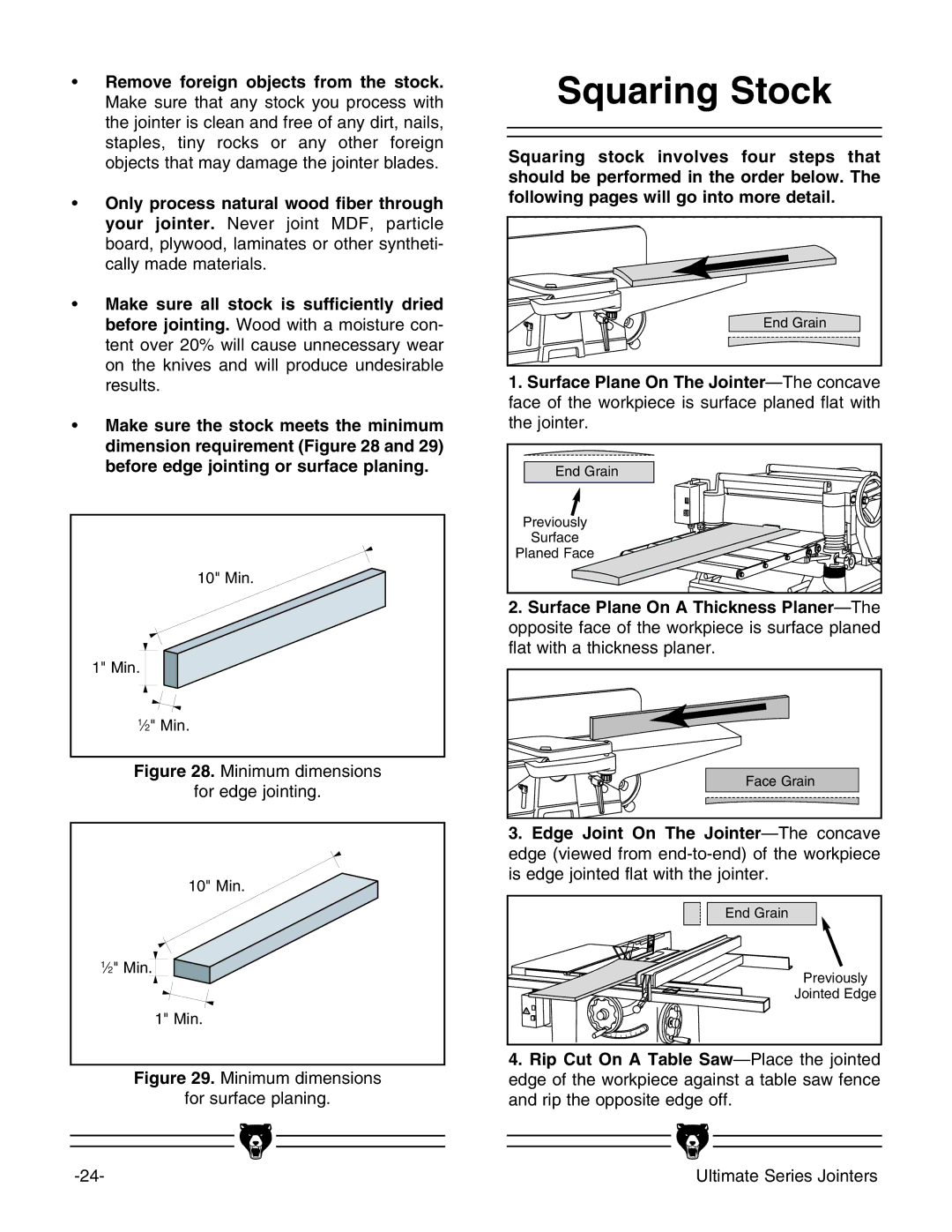

•Make sure the stock meets the minimum dimension requirement (Figure 28 and 29) before edge jointing or surface planing.

10" Min.

1" Min.

1⁄2" Min.

Figure 28. Minimum dimensions

for edge jointing.

10" Min.

1⁄2" Min.

1" Min.

Figure 29. Minimum dimensions

for surface planing.

Squaring Stock

Squaring stock involves four steps that should be performed in the order below. The following pages will go into more detail.

End Grain |

1.Surface Plane On The

End Grain |

Previously |

Surface |

Planed Face |

2.Surface Plane On A Thickness

Face Grain |

3.Edge Joint On The

| End Grain |

| Previously |

| Jointed Edge |

| 45 |

15 | 30 |

4.Rip Cut On A Table

Ultimate Series Jointers |