Contents

220 VAC*DUAL MIG Welder

For technical questions or replacement parts, please call

Contents

Work Area

Product Specifications

General Safety Rules

Save this Manual

Personal Safety

Electrical Safety

Tool USE and Care

Service

Industrial applications must follow Osha guidelines

Specific Safety Rules

Page

Welding Produces toxic fumes and gasses

Cylinders can explode when damaged

Grounding

Grounded Tools Tools with Three Prong Plugs

Symbology

Unpacking

Extension Cords

To Attach The Handle

Assembly Instructions

Face Shield Assembly

To Install a Wire Spool

See Figure E

To Route The Wire

Figure F

Exercise Extreme Caution Risk of Fire AND/OR Electric Shock

To Change Wire Settings

See Figure G

Nozzle. See Figure F, previous

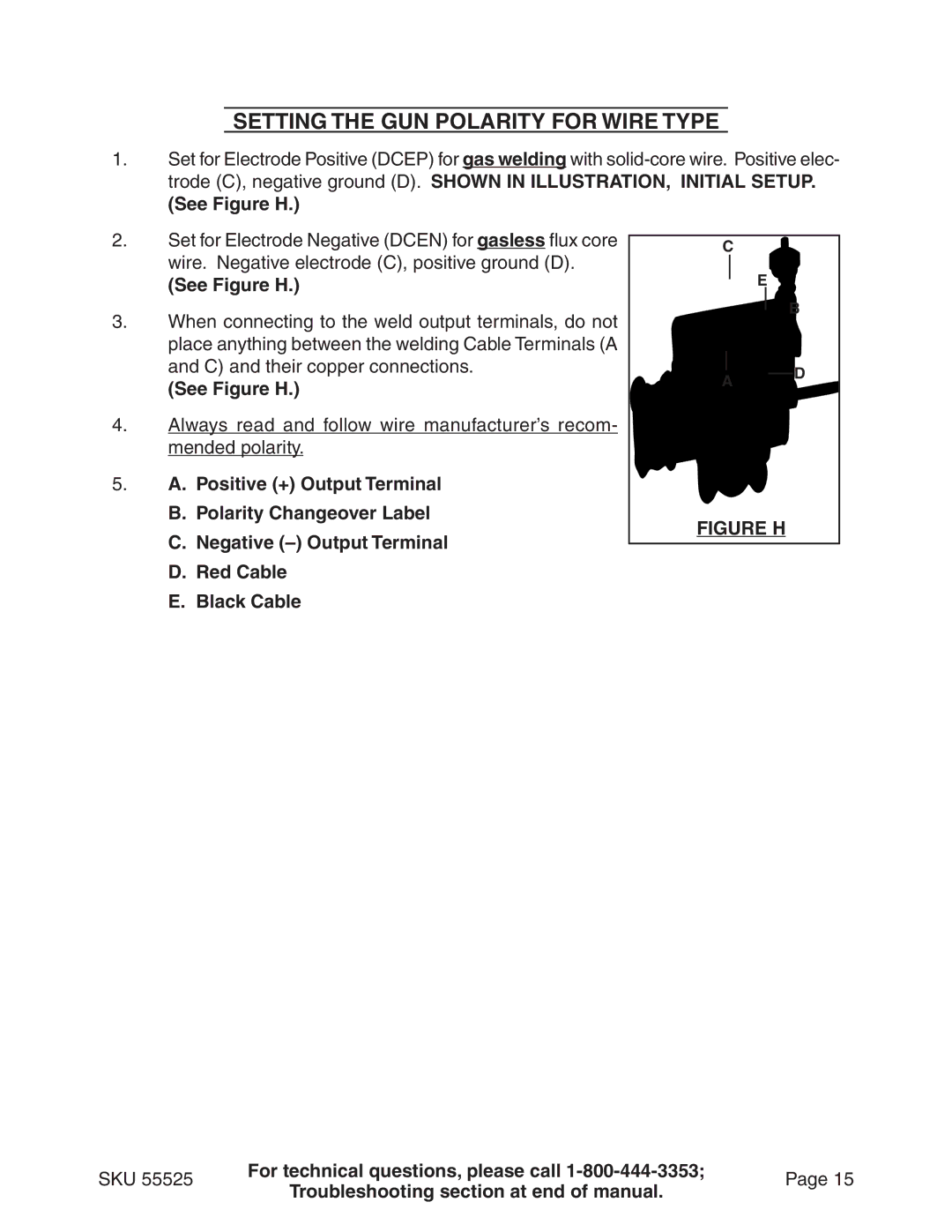

See Figure H

Setting The Gun Polarity For Wire Type

To Install a Gas Cylinder

See Figure K

Operating Instructions

Before You Begin Welding

Duty Cycle Duration of Use

See Figure L

Setting Up The Weld

Figure M

Holding The Welding Torch

On ET

OttomB number is Wire

HarsgCni ttSe eldW

Top figures are Voltage

Page

Weld Diagnosis Weld Penetration

Weld Not Adhering Properly

Bend at joint

Porosity

Excessive Spatter

Strike Test

When the Weld is Completed

Or more for .030Tips .035 or more for .023 Tips

INSPECTION, MAINTENANCE, and Cleaning

Nozzle Inspection, Cleaning, and Replacement

Contact Tip Inspection, Cleaning, And Replacement

Please Read the Following Carefully

Replacing The Welding Torch Liner

Wiring Schematic

Parts Lists and Diagrams

Part Description Qty

Parts List

Assembly Diagram

Assembly Diagram Wire Feed Mechanism

Welding arc not stable

Troubleshooting

Wire feed motor runs but wire does not feed properly

Wire creates a bird’s nest During operation

Weak Arc strength

Welder does not function when switched on

Wire Feeds, but arc does not ignite

Troubleshooting

Regulator or cylinder valve closed

Wire Feeds, but Shielding gas does not Flow

Warranty

Nozzle Plugged