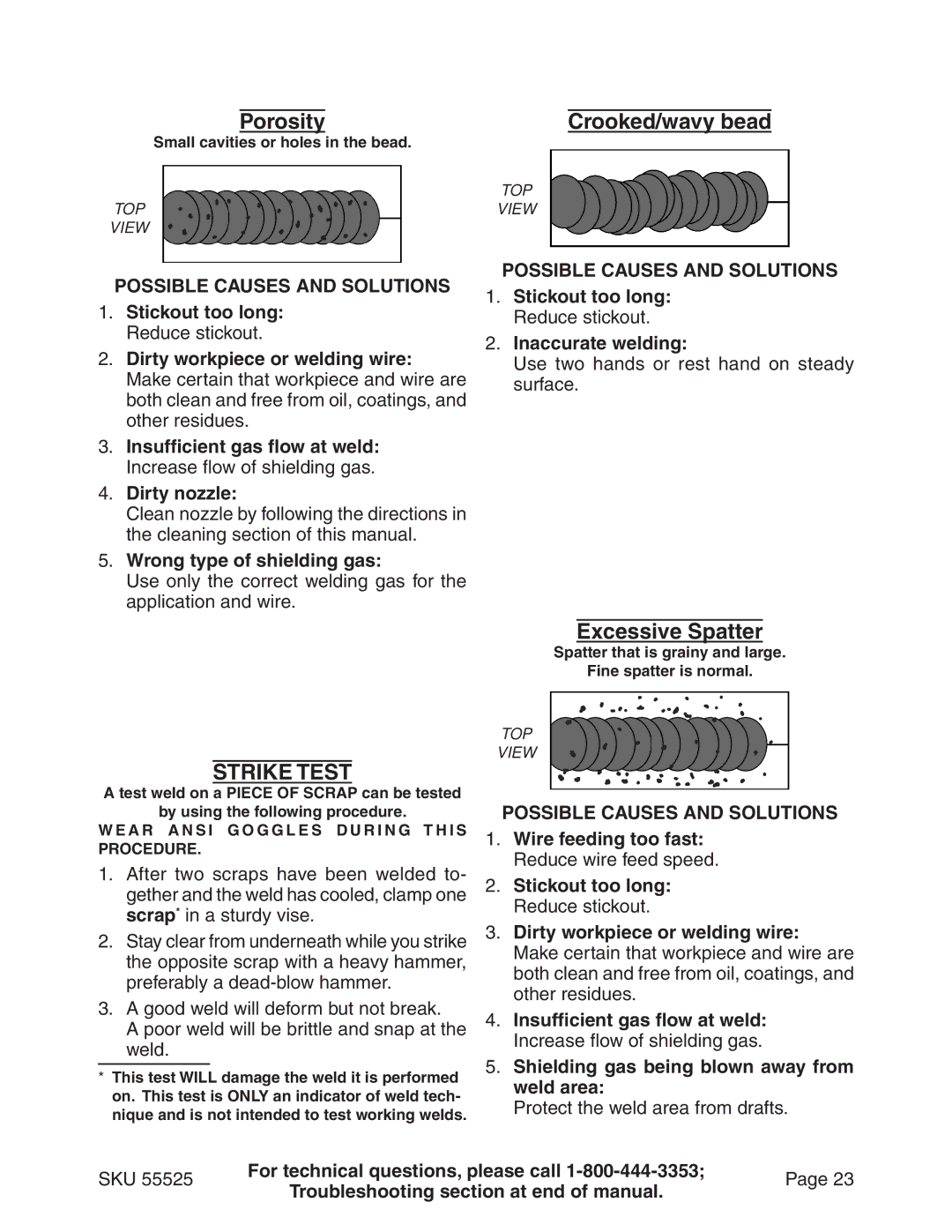

Porosity | Crooked/wavy bead |

Small cavities or holes in the bead.

Top

View

Possible Causes and Solutions

1.Stickout too long: Reduce stickout.

2.Dirty workpiece or welding wire: Make certain that workpiece and wire are both clean and free from oil, coatings, and other residues.

3.Insufficient gas flow at weld: Increase flow of shielding gas.

4.Dirty nozzle:

Clean nozzle by following the directions in the cleaning section of this manual.

5.Wrong type of shielding gas:

Use only the correct welding gas for the application and wire.

Top

View

Possible Causes and Solutions

1.Stickout too long: Reduce stickout.

2.Inaccurate welding:

Use two hands or rest hand on steady surface.

Excessive Spatter

Spatter that is grainy and large.

Fine spatter is normal.

STRIKE TEST

A test weld on a piece of scrap can be tested

by using the following procedure.

W E A R A N S I G O G G L E S D U R I N G T H I S PROCEDURE.

1.After two scraps have been welded to- gether and the weld has cooled, clamp one scrap in a sturdy vise.

2.Stay clear from underneath while you strike the opposite scrap with a heavy hammer, preferably a

3.A good weld will deform but not break.

A poor weld will be brittle and snap at the weld.

This test will damage the weld it is performed on. This test is only an indicator of weld tech- nique and is not intended to test working welds.

Top

View

Possible Causes and Solutions

1.Wire feeding too fast: Reduce wire feed speed.

2.Stickout too long: Reduce stickout.

3.Dirty workpiece or welding wire: Make certain that workpiece and wire are both clean and free from oil, coatings, and other residues.

4.Insufficient gas flow at weld: Increase flow of shielding gas.

5.Shielding gas being blown away from weld area:

Protect the weld area from drafts.

SKU 55525 | For technical questions, please call | Page 23 | |

Troubleshooting section at end of manual. | |||

|

|