Maintenance - Cleaning the Feeder Body

Pellet fines may accumulate in the feeder body over a period of time; therefore, a yearly inspection and cleaning of this area must be performed.

To clean out fines:

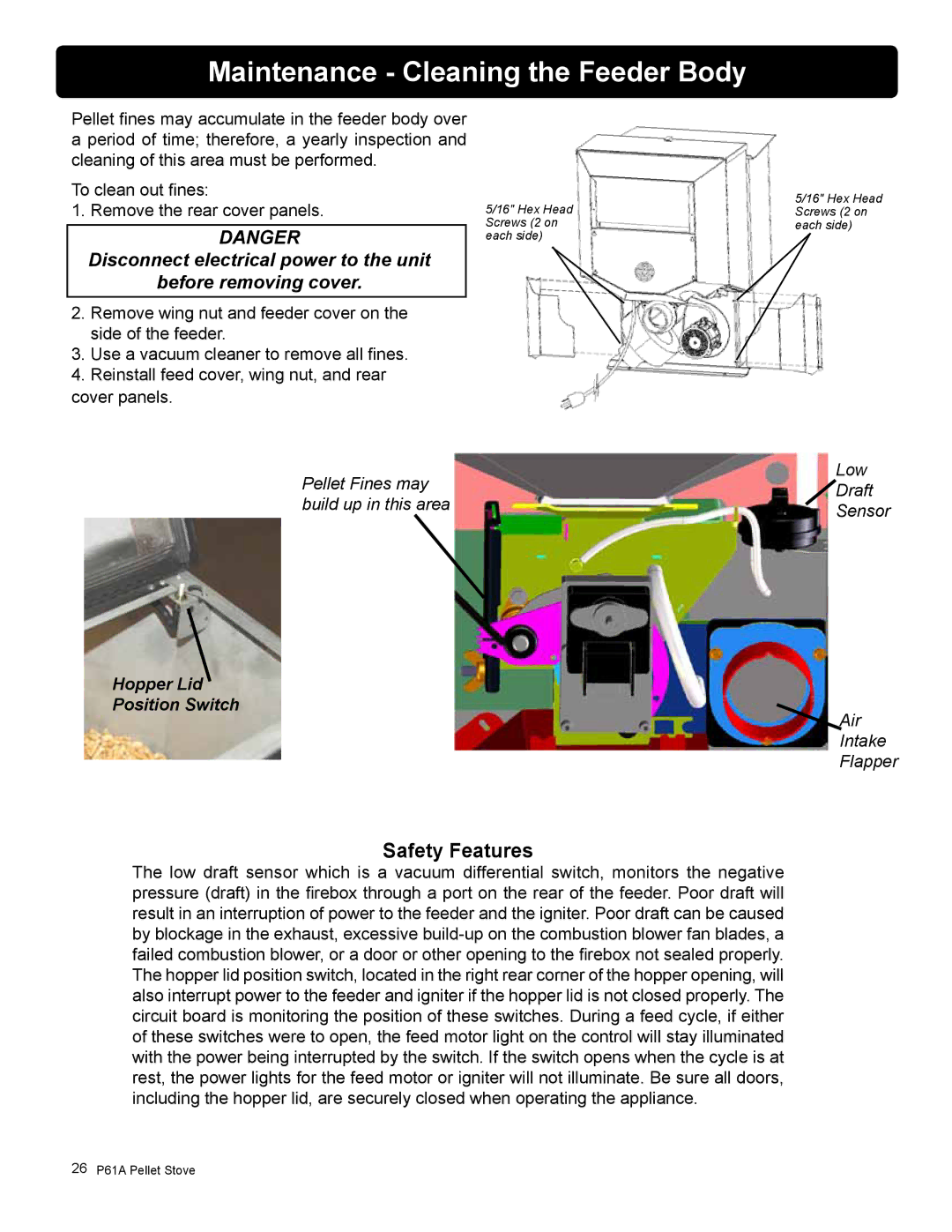

1. Remove the rear cover panels.

DANGER

Disconnect electrical power to the unit

before removing cover.

2.Remove wing nut and feeder cover on the side of the feeder.

3.Use a vacuum cleaner to remove all fines.

4.Reinstall feed cover, wing nut, and rear cover panels.

5/16" Hex Head Screws (2 on each side)

5/16" Hex Head Screws (2 on each side)

Pellet Fines may build up in this area

Hopper Lid

Position Switch

Low

Draft

Sensor

![]() Air

Air

Intake

Flapper

Safety Features

The low draft sensor which is a vacuum differential switch, monitors the negative pressure (draft) in the firebox through a port on the rear of the feeder. Poor draft will result in an interruption of power to the feeder and the igniter. Poor draft can be caused by blockage in the exhaust, excessive

26P61A Pellet Stove