6.0 Lubrication

6.1Air Hoist Lubrication

6.1.1 See Section 3.0 for lubrication requirements.

![]()

![]() Lubrication to the motor will be provided primarily by the air supply lubricator. The recommended amount is

Lubrication to the motor will be provided primarily by the air supply lubricator. The recommended amount is

6.1.3Additional lubrication to the reduction gears is not necessary. When disassembling the hoist for service or repair, apply new grease to the gears before reassembling the hoist.

6.2Load Chain Lubrication

6.2.1For longer life, lightly coat the load chain with machine or gear oil. Ensure that the oil is applied to the bearing surfaces of the load chain links.

6.2.2The load chain lubrication should be accomplished after cleaning the load chain with acid free cleaning solution. Use approved lubricant in Table

6.2.3For dusty environments, it is acceptable to substitute a dry lubricant.

6.3Hooks and Suspension Components

6.3.1Hooks - Bearings should be cleaned and lubricated at least once per year for normal usage. Clean and lubricate more frequently for heavier usage or severe conditions.

6.3.2Suspension Pins - Lubricate at least twice per year for normal usage; more frequently for heavier usage or severe conditions.

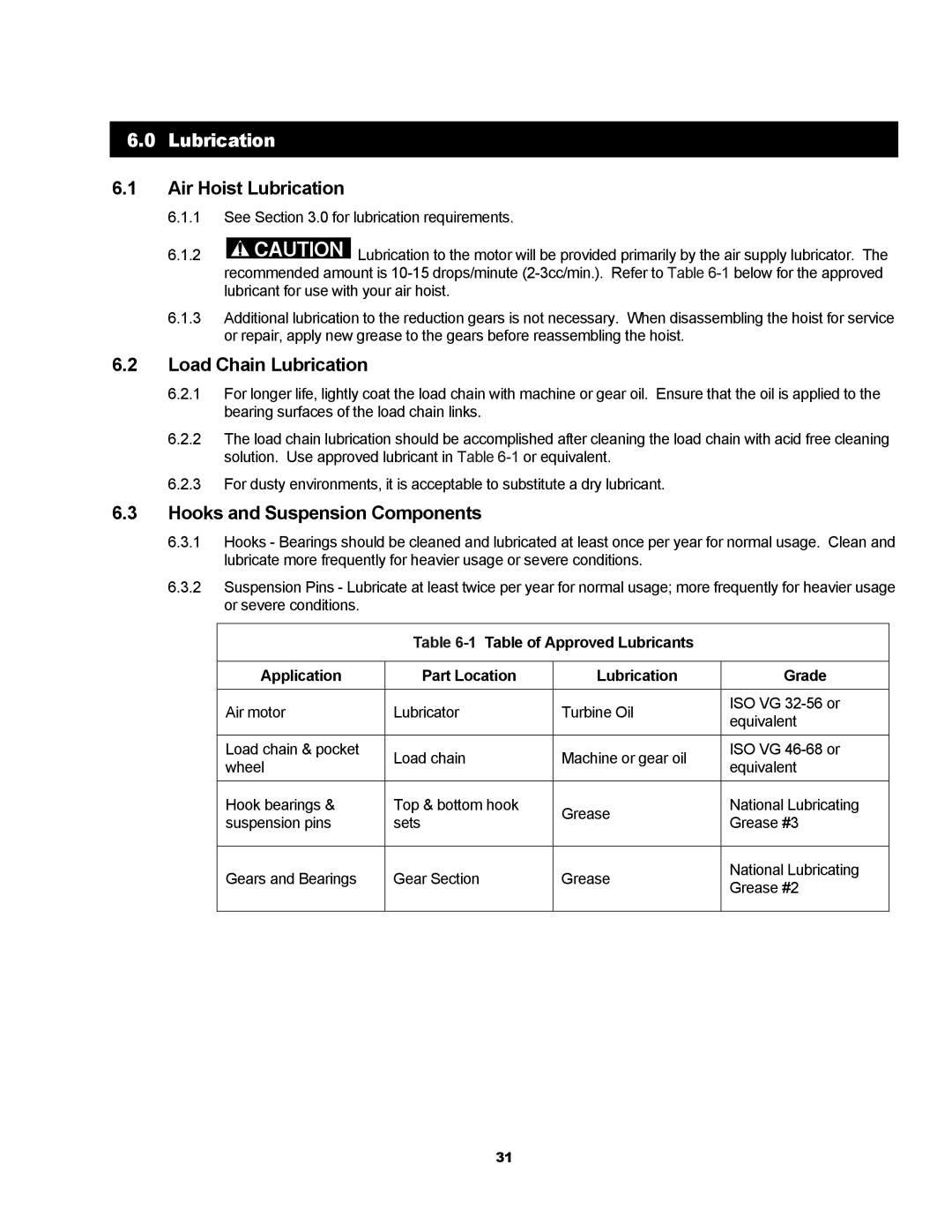

Table

Application | Part Location | Lubrication | Grade | |

|

|

|

| |

Air motor | Lubricator | Turbine Oil | ISO VG | |

equivalent | ||||

|

|

| ||

|

|

|

| |

Load chain & pocket | Load chain | Machine or gear oil | ISO VG | |

wheel | equivalent | |||

|

| |||

Hook bearings & | Top & bottom hook | Grease | National Lubricating | |

suspension pins | sets | Grease #3 | ||

| ||||

|

|

|

| |

Gears and Bearings | Gear Section | Grease | National Lubricating | |

Grease #2 | ||||

|

|

| ||

|

|

|

|

31