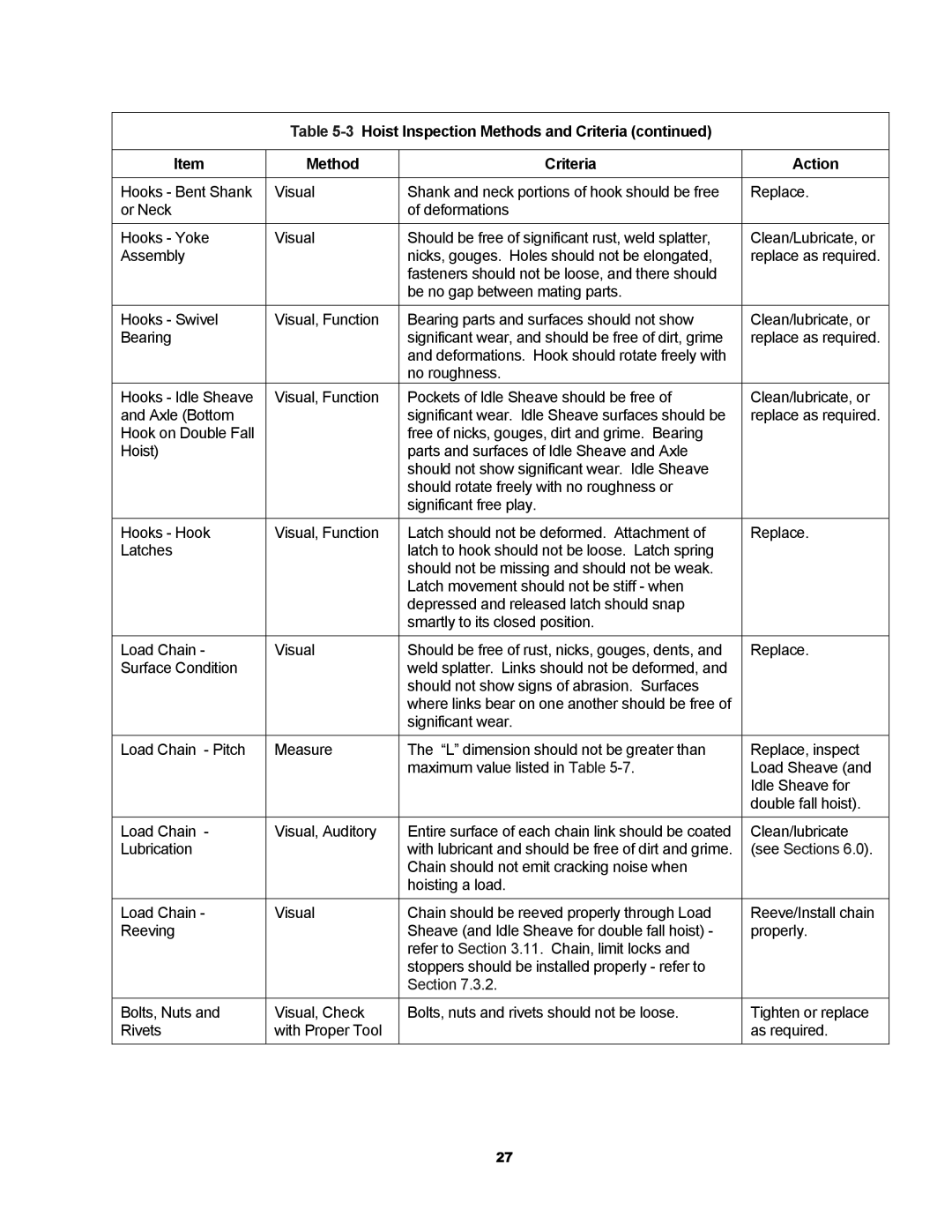

Table 5-3 Hoist Inspection Methods and Criteria (continued)

Item | Method | Criteria | Action |

|

|

|

|

Hooks - Bent Shank | Visual | Shank and neck portions of hook should be free | Replace. |

or Neck |

| of deformations |

|

Hooks - Yoke | Visual | Should be free of significant rust, weld splatter, | Clean/Lubricate, or |

Assembly |

| nicks, gouges. Holes should not be elongated, | replace as required. |

|

| fasteners should not be loose, and there should |

|

|

| be no gap between mating parts. |

|

Hooks - Swivel | Visual, Function | Bearing parts and surfaces should not show | Clean/lubricate, or |

Bearing |

| significant wear, and should be free of dirt, grime | replace as required. |

|

| and deformations. Hook should rotate freely with |

|

|

| no roughness. |

|

Hooks - Idle Sheave | Visual, Function | Pockets of Idle Sheave should be free of | Clean/lubricate, or |

and Axle (Bottom |

| significant wear. Idle Sheave surfaces should be | replace as required. |

Hook on Double Fall |

| free of nicks, gouges, dirt and grime. Bearing |

|

Hoist) |

| parts and surfaces of Idle Sheave and Axle |

|

|

| should not show significant wear. Idle Sheave |

|

|

| should rotate freely with no roughness or |

|

|

| significant free play. |

|

|

|

|

|

Hooks - Hook | Visual, Function | Latch should not be deformed. Attachment of | Replace. |

Latches |

| latch to hook should not be loose. Latch spring |

|

|

| should not be missing and should not be weak. |

|

|

| Latch movement should not be stiff - when |

|

|

| depressed and released latch should snap |

|

|

| smartly to its closed position. |

|

|

|

|

|

Load Chain - | Visual | Should be free of rust, nicks, gouges, dents, and | Replace. |

Surface Condition |

| weld splatter. Links should not be deformed, and |

|

|

| should not show signs of abrasion. Surfaces |

|

|

| where links bear on one another should be free of |

|

|

| significant wear. |

|

|

|

|

|

Load Chain - Pitch | Measure | The “L” dimension should not be greater than | Replace, inspect |

|

| maximum value listed in Table | Load Sheave (and |

|

|

| Idle Sheave for |

|

|

| double fall hoist). |

|

|

|

|

Load Chain - | Visual, Auditory | Entire surface of each chain link should be coated | Clean/lubricate |

Lubrication |

| with lubricant and should be free of dirt and grime. | (see Sections 6.0). |

|

| Chain should not emit cracking noise when |

|

|

| hoisting a load. |

|

|

|

|

|

Load Chain - | Visual | Chain should be reeved properly through Load | Reeve/Install chain |

Reeving |

| Sheave (and Idle Sheave for double fall hoist) - | properly. |

|

| refer to Section 3.11. Chain, limit locks and |

|

|

| stoppers should be installed properly - refer to |

|

|

| Section 7.3.2. |

|

Bolts, Nuts and | Visual, Check | Bolts, nuts and rivets should not be loose. | Tighten or replace |

Rivets | with Proper Tool |

| as required. |

|

|

|

|

27