North Star

EPA Certified Fireplace

14.Installing the Roof Flashing

If a roof flashing is to be used, install the roof flashing appropriate to the roof pitch and install a round termination cap following the instructions shipped with the cap.

For chase installations you can use a round termination cap (TR344), a round telescoping termination cap (TR342) or a square termination cap (ST375). A chase installation must use a chase top. Chase tops are available from your dealer. See page 19 for building a chase.

15.Completion of the Enclosure

Complete the fireplace enclosure, allowing space for outside air ducts. Electrical wiring should not come in contact with the fireplace. A minimum clearance of 1” must be maintained between the fireplace sides and back and the enclosure. See pages

16.Hearth Extension

A hearth extension must be installed with all fireplaces to protect the combustible floor in front of the fireplace from both radiant heat and sparks.

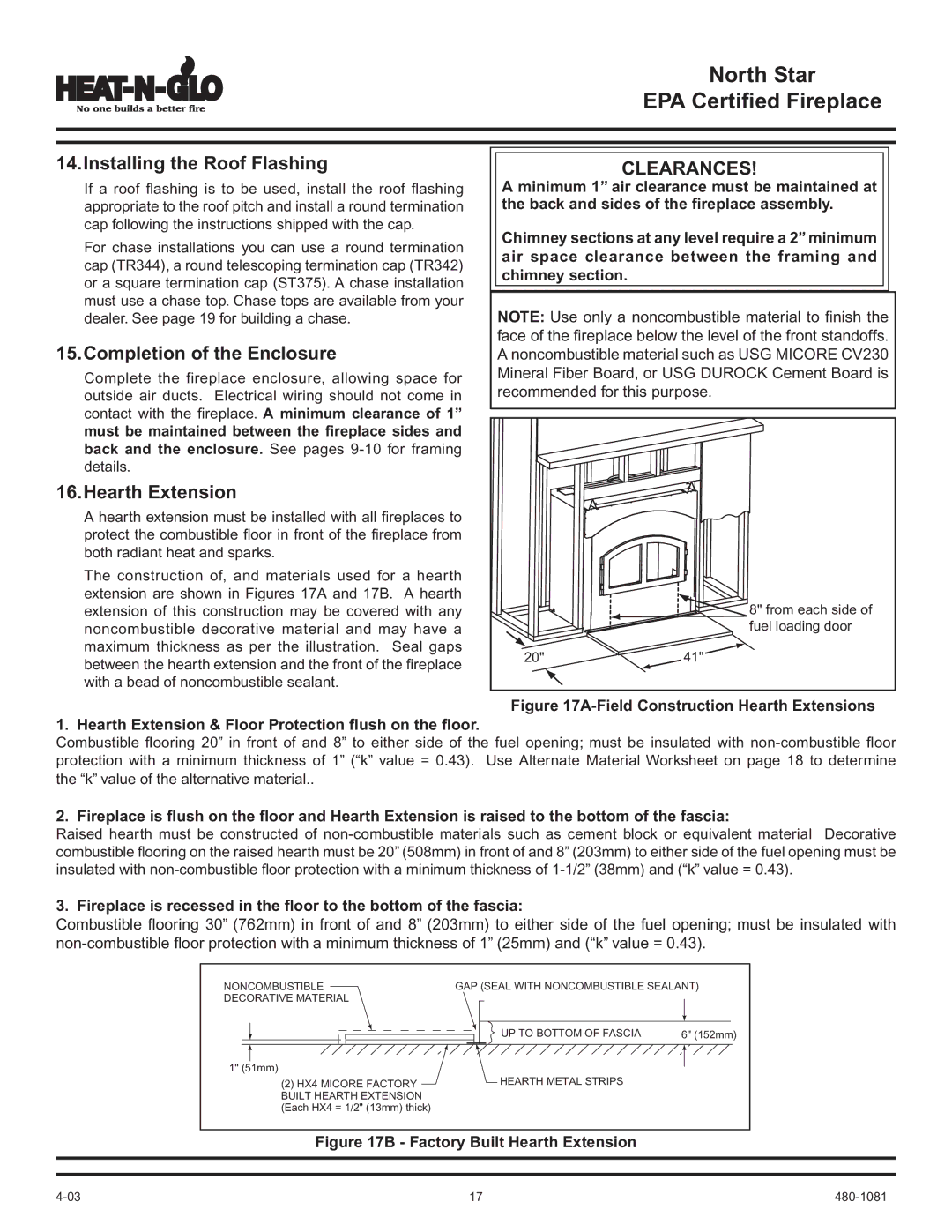

The construction of, and materials used for a hearth extension are shown in Figures 17A and 17B. A hearth extension of this construction may be covered with any noncombustible decorative material and may have a maximum thickness as per the illustration. Seal gaps between the hearth extension and the front of the fireplace with a bead of noncombustible sealant.

CLEARANCES!

A minimum 1” air clearance must be maintained at the back and sides of the fireplace assembly.

Chimney sections at any level require a 2” minimum air space clearance between the framing and chimney section.

NOTE: Use only a noncombustible material to finish the face of the fireplace below the level of the front standoffs. A noncombustible material such as USG MICORE CV230 Mineral Fiber Board, or USG DUROCK Cement Board is recommended for this purpose.

8" from each side of fuel loading door

20"41"

Figure 17A-Field Construction Hearth Extensions

1. Hearth Extension & Floor Protection flush on the floor.

Combustible flooring 20” in front of and 8” to either side of the fuel opening; must be insulated with

2. Fireplace is flush on the floor and Hearth Extension is raised to the bottom of the fascia:

Raised hearth must be constructed of

3. Fireplace is recessed in the floor to the bottom of the fascia:

Combustible flooring 30” (762mm) in front of and 8” (203mm) to either side of the fuel opening; must be insulated with

NONCOMBUSTIBLE | GAP (SEAL WITH NONCOMBUSTIBLE SEALANT) | |

DECORATIVE MATERIAL |

|

|

|

| |

|

|

|

1" (51mm)

(2)HX4 MICORE FACTORY BUILT HEARTH EXTENSION (Each HX4 = 1/2" (13mm) thick)

UP TO BOTTOM OF FASCIA | 6" (152mm) |

HEARTH METAL STRIPS

Figure 17B - Factory Built Hearth Extension

17 |