3.To install the round support box/wall thimble cover in a flat ceiling, cut a 10 in. (254 mm) square hole in the ceiling, centered on the hole drilled in Step 2. Frame

the hole as shown in Figure 5.13. | SHINGLES OVERLAP ON | CAP AND STORM |

| TOP EDGE OF FLASHING | |

|

| COLLAR NOT SHOWN |

|

| FOR CLARITY |

| CEILING JOISTS |

|

FRAMING |

|

|

ROUND CEILING

SUPPORT BOX/WALL

THIMBLE COVER

Figure 5.14

|

| 7. | Continue to assemble pipe sections until the height of | |||

| LONG WOOD |

| ||||

| SCREWS |

|

| the vent (before adding the termination cap) meets the | ||

| Figure 5.13 |

|

|

| minimum code requirements as outlined in the current | |

|

|

|

|

| ||

4. Assemble the desired lengths of | pipe and elbows |

| National Fuel Gas Code NFPA 54/ANSI Z223.1 (in | |||

| USA), or local codes. Note that for steep roof pitches, | |||||

| necessary to reach from the appliance up through |

| the vent height must be increased. | See Roof Pitch | ||

| the round support box. Ensure that all pipe and elbow |

| Table (Figure 4.3, on page 9). In high wind conditions, | |||

| connections are in their fully |

| nearby trees adjoining rooflines, steep pitched roofs, | |||

| Assemble as instructed. |

|

|

| and other similar factors can result in poor draft, or | |

5. | Cut a hole in the roof centered on the small drill hole |

| down drafting. In these cases increasing the vent | |||

| placed in the roof in Step 2. The hole should be of |

| height or switching to the high wind termination cap | |||

| sufficient size to meet the minimum requirements for |

| may solve this problem. |

| ||

| clearance to combustibles, as specified. | Continue | 8. | Slip the storm collar over the pipe, and push it down | ||

| to assemble lengths of pipe and elbows necessary |

| to the top of the flashing (Figure 5.15). Use non- | |||

| to reach from the ceiling support box/wall thimble up |

| hardening sealant above and below the joint between | |||

| through the roof line. Galvanized pipe and elbows may |

| the storm collar and the pipe. |

| ||

| be utilized in the attic, as well as above the roofline. |

|

|

| ||

| The galvanized finish is desirable above the roofline, |

|

|

| ||

| due to its higher corrosion resistance. |

|

|

|

| |

| • If an offset is necessary in the attic to avoid |

|

|

| ||

| obstructions, it is important to support the vent pipe |

| OPTIONAL HIGH WIND |

| ||

| every 3 ft. (914 mm) to avoid excessive stress on the |

| TERMINATION CAP |

| ||

|

| SECURE FLASHING WITH |

| |||

| elbows, and possible separation. | Wall straps are |

|

| ||

| available for this purpose, Figure 5.12, page 16. |

|

| |||

|

| ROOFING NAILS |

| |||

| • Whenever possible, use 45° elbows, instead of 90° |

|

|

| ||

| elbows. The 45° elbow offers less restriction to the |

|

|

| ||

| flow of flue gases and intake air. |

|

|

|

|

|

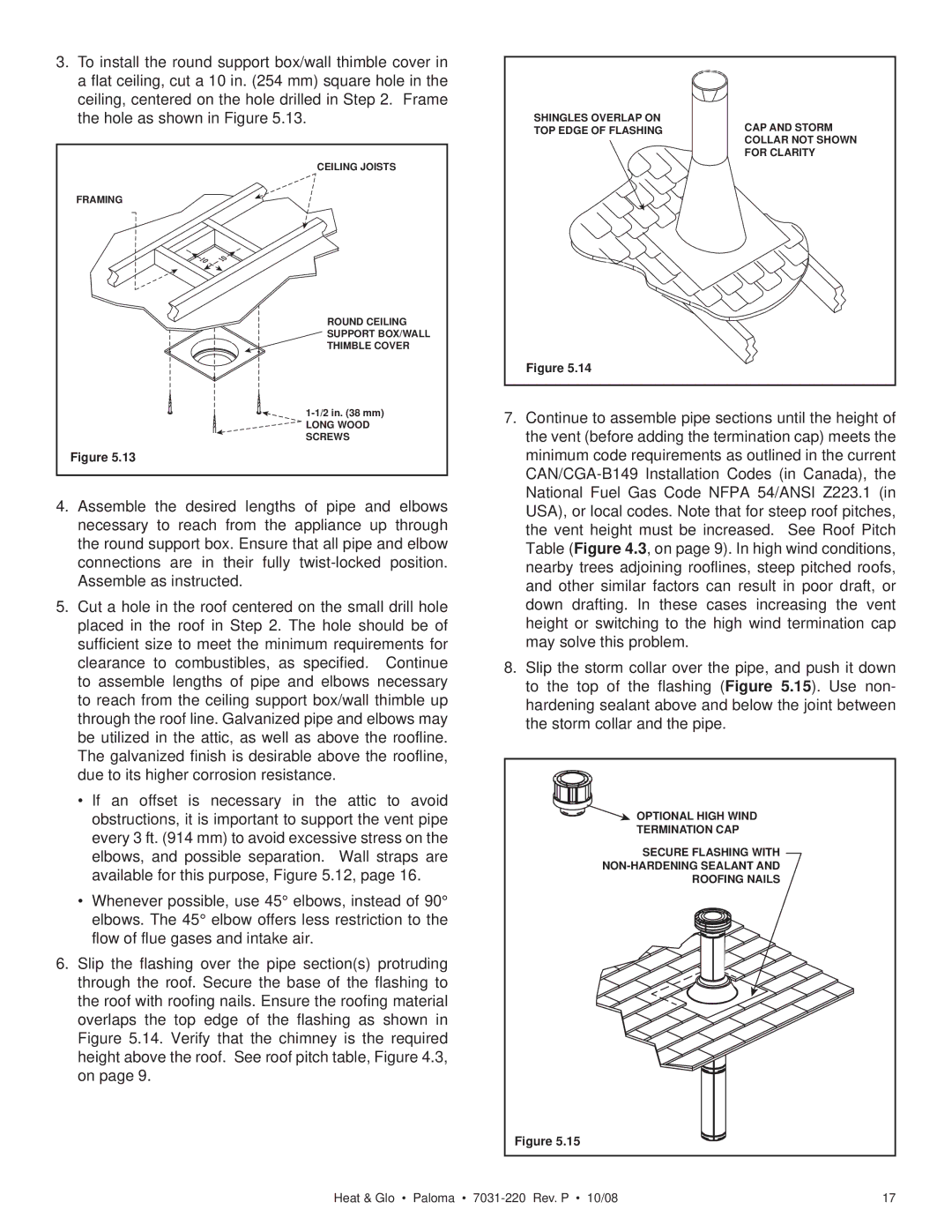

6. Slip the flashing over the pipe section(s) protruding |

|

|

| |||

| through the roof. Secure the base of the flashing to |

|

|

| ||

| the roof with roofing nails. Ensure the roofing material |

|

|

| ||

| overlaps the top edge of the flashing as shown in |

|

|

| ||

| Figure 5.14. Verify that the chimney is the required |

|

|

| ||

| height above the roof. See roof pitch table, Figure 4.3, |

|

|

| ||

| on page 9. |

|

|

|

|

|

|

|

|

| Figure 5.15 |

| |

|

| Heat & Glo • Paloma • | 17 | |||