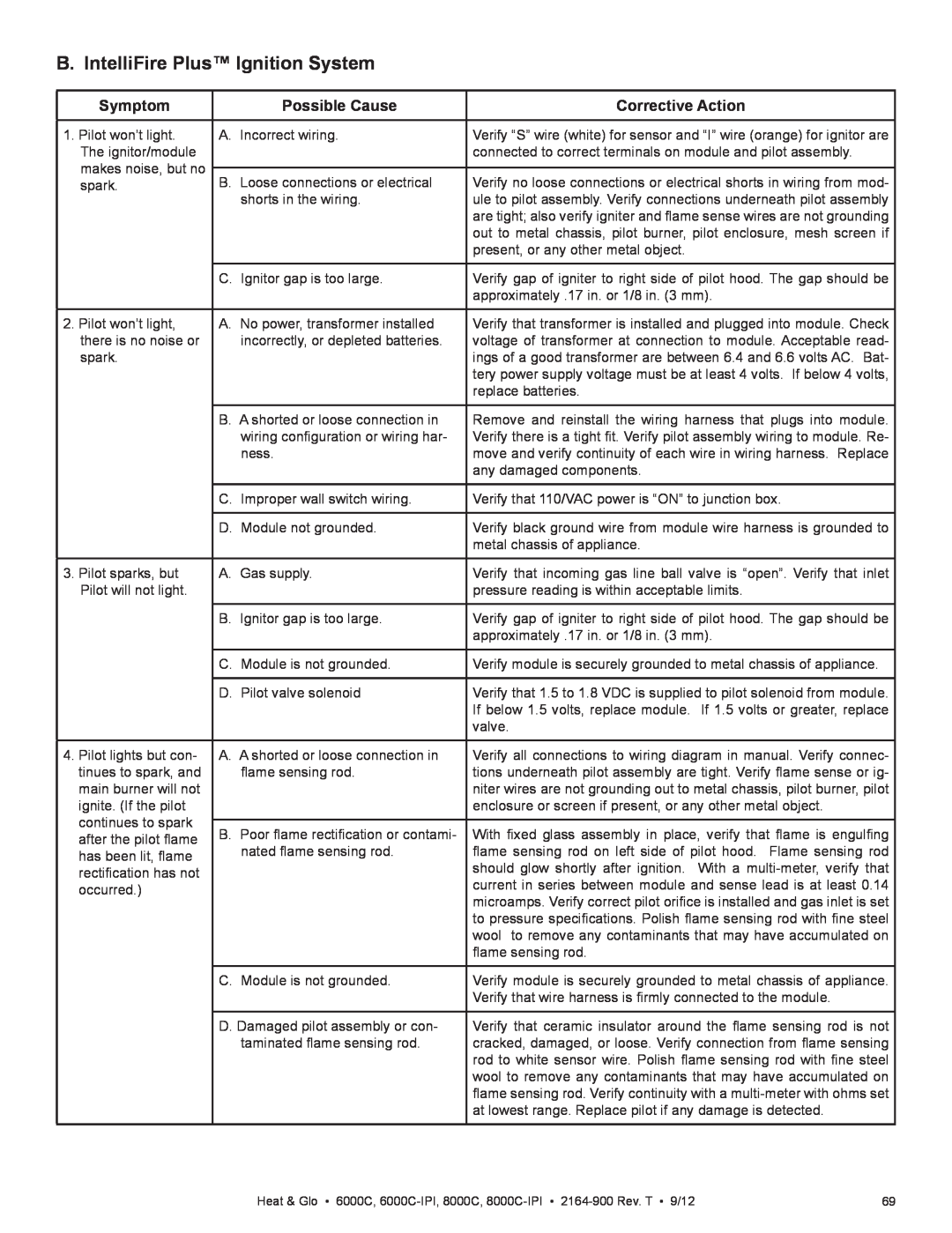

B. IntelliFire Plus™ Ignition System

Symptom | Possible Cause | Corrective Action | |

|

|

| |

1. Pilot won’t light. | A. Incorrect wiring. | Verify “S” wire (white) for sensor and “I” wire (orange) for ignitor are | |

The ignitor/module |

| connected to correct terminals on module and pilot assembly. | |

makes noise, but no |

|

| |

B. Loose connections or electrical | Verify no loose connections or electrical shorts in wiring from mod- | ||

spark. | |||

| shorts in the wiring. | ule to pilot assembly. Verify connections underneath pilot assembly | |

|

| are tight; also verify igniter and flame sense wires are not grounding | |

|

| out to metal chassis, pilot burner, pilot enclosure, mesh screen if | |

|

| present, or any other metal object. | |

|

|

| |

| C. Ignitor gap is too large. | Verify gap of igniter to right side of pilot hood. The gap should be | |

|

| approximately .17 in. or 1/8 in. (3 mm). | |

|

|

| |

2. Pilot won’t light, | A. No power, transformer installed | Verify that transformer is installed and plugged into module. Check | |

there is no noise or | incorrectly, or depleted batteries. | voltage of transformer at connection to module. Acceptable read- | |

spark. |

| ings of a good transformer are between 6.4 and 6.6 volts AC. Bat- | |

|

| tery power supply voltage must be at least 4 volts. If below 4 volts, | |

|

| replace batteries. | |

|

|

| |

| B. A shorted or loose connection in | Remove and reinstall the wiring harness that plugs into module. | |

| wiring configuration or wiring har- | Verify there is a tight fit. Verify pilot assembly wiring to module. Re- | |

| ness. | move and verify continuity of each wire in wiring harness. Replace | |

|

| any damaged components. | |

|

|

| |

| C. Improper wall switch wiring. | Verify that 110/VAC power is “ON” to junction box. | |

|

|

| |

| D. Module not grounded. | Verify black ground wire from module wire harness is grounded to | |

|

| metal chassis of appliance. | |

|

|

| |

3. Pilot sparks, but | A. Gas supply. | Verify that incoming gas line ball valve is “open”. Verify that inlet | |

Pilot will not light. |

| pressure reading is within acceptable limits. | |

|

|

| |

| B. Ignitor gap is too large. | Verify gap of igniter to right side of pilot hood. The gap should be | |

|

| approximately .17 in. or 1/8 in. (3 mm). | |

|

|

| |

| C. Module is not grounded. | Verify module is securely grounded to metal chassis of appliance. | |

|

|

| |

| D. Pilot valve solenoid | Verify that 1.5 to 1.8 VDC is supplied to pilot solenoid from module. | |

|

| If below 1.5 volts, replace module. If 1.5 volts or greater, replace | |

|

| valve. | |

|

|

| |

4. Pilot lights but con- | A. A shorted or loose connection in | Verify all connections to wiring diagram in manual. Verify connec- | |

tinues to spark, and | flame sensing rod. | tions underneath pilot assembly are tight. Verify flame sense or ig- | |

main burner will not |

| niter wires are not grounding out to metal chassis, pilot burner, pilot | |

ignite. (If the pilot |

| enclosure or screen if present, or any other metal object. | |

continues to spark |

|

| |

B. Poor flame rectification or contami- | With fixed glass assembly in place, verify that flame is engulfing | ||

after the pilot flame | |||

nated flame sensing rod. | flame sensing rod on left side of pilot hood. Flame sensing rod | ||

has been lit, flame | |||

| should glow shortly after ignition. With a | ||

rectification has not |

| ||

| current in series between module and sense lead is at least 0.14 | ||

occurred.) |

| ||

| microamps. Verify correct pilot orifice is installed and gas inlet is set | ||

|

| ||

|

| to pressure specifications. Polish flame sensing rod with fine steel | |

|

| wool to remove any contaminants that may have accumulated on | |

|

| flame sensing rod. | |

|

|

| |

| C. Module is not grounded. | Verify module is securely grounded to metal chassis of appliance. | |

|

| Verify that wire harness is firmly connected to the module. | |

|

|

| |

| D. Damaged pilot assembly or con- | Verify that ceramic insulator around the flame sensing rod is not | |

| taminated flame sensing rod. | cracked, damaged, or loose. Verify connection from flame sensing | |

|

| rod to white sensor wire. Polish flame sensing rod with fine steel | |

|

| wool to remove any contaminants that may have accumulated on | |

|

| flame sensing rod. Verify continuity with a | |

|

| at lowest range. Replace pilot if any damage is detected. | |

|

|

|

Heat & Glo • 6000C, | 69 |