CAUTION

Ensure that existing chimney is functionally sound and clean.

•Have inspection done by qualified chimney sweep or professional installer BEFORE converting to direct vent appliance.

Step 1.

Before cutting any holes, assemble the desired sections of direct vent pipe to determine the center of the masonry penetration.

Step 2.

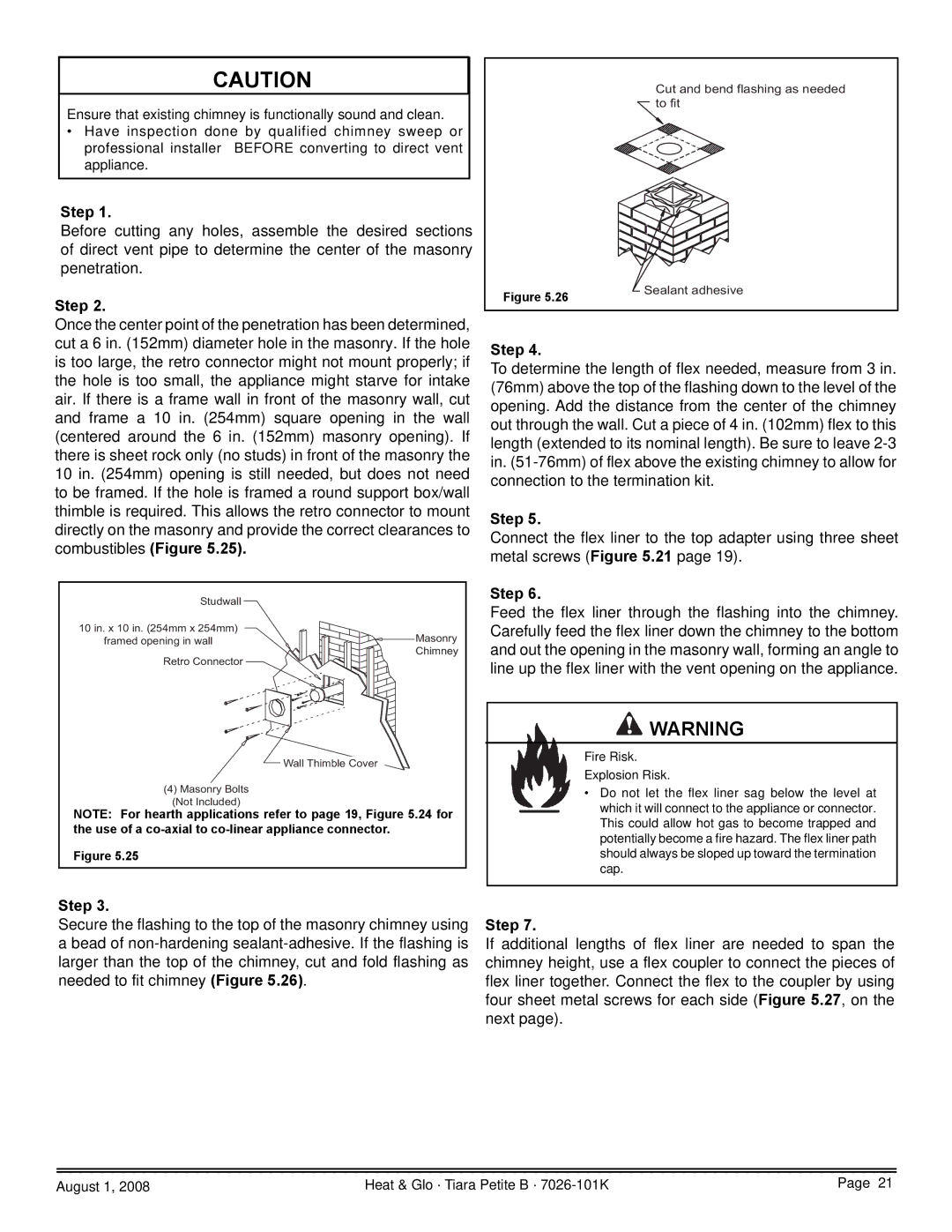

Once the center point of the penetration has been determined, cut a 6 in. (152mm) diameter hole in the masonry. If the hole is too large, the retro connector might not mount properly; if the hole is too small, the appliance might starve for intake air. If there is a frame wall in front of the masonry wall, cut and frame a 10 in. (254mm) square opening in the wall (centered around the 6 in. (152mm) masonry opening). If there is sheet rock only (no studs) in front of the masonry the 10 in. (254mm) opening is still needed, but does not need to be framed. If the hole is framed a round support box/wall thimble is required. This allows the retro connector to mount directly on the masonry and provide the correct clearances to combustibles (Figure 5.25).

Studwall

10 in. x 10 in. (254mm x 254mm)

framed opening in wallMasonry Chimney

Retro Connector

Wall Thimble Cover

(4) Masonry Bolts

(Not Included)

NOTE: For hearth applications refer to page 19, Figure 5.24 for the use of a

Figure 5.25

Cut and bend flashing as needed to fit

Figure 5.26 | Sealant adhesive |

|

Step 4.

To determine the length of flex needed, measure from 3 in. (76mm) above the top of the flashing down to the level of the opening. Add the distance from the center of the chimney out through the wall. Cut a piece of 4 in. (102mm) flex to this length (extended to its nominal length). Be sure to leave

Step 5.

Connect the flex liner to the top adapter using three sheet metal screws (Figure 5.21 page 19).

Step 6.

Feed the flex liner through the flashing into the chimney. Carefully feed the flex liner down the chimney to the bottom and out the opening in the masonry wall, forming an angle to line up the flex liner with the vent opening on the appliance.

![]() WARNING

WARNING

Fire Risk.

Explosion Risk.

•Do not let the flex liner sag below the level at which it will connect to the appliance or connector. This could allow hot gas to become trapped and potentially become a fire hazard. The flex liner path should always be sloped up toward the termination cap.

Step 3.

Secure the flashing to the top of the masonry chimney using a bead of

Step 7.

If additional lengths of flex liner are needed to span the chimney height, use a flex coupler to connect the pieces of flex liner together. Connect the flex to the coupler by using four sheet metal screws for each side (Figure 5.27, on the next page).

August 1, 2008 | Heat & Glo · Tiara Petite B · | Page 21 |