Air Conditioning/Heat Pump

Only for authorized service personnel

HEAT CONTROLLER, INC

Wall Mounted Multi-SplitSystem

TABLE OF CONTENTS

2Multi type Air Conditioner

Combination table

SymbolsUsedinthisManual

Service Manual

Combination table

4Multi type Air Conditioner

Safety Precautions

Installation

Safety Precautions

Do not install, remove, or re

Safety Precautions

Service Manual

an Authorized Service Center

6Multi type Air Conditioner

Safety Precautions

When the product is soaked

installing the product

Installation

Safety Precautions

Install the drain hose to ensure that

8Multi type Air Conditioner

Operational

Safety Precautions

•They may burn or explode

Safety Precautions

Service Manual

•Be careful and avoid personal injury

Split Type Indoor

Dimensions

Dimensions

IndoorUnit

UE 18kBtu/h

OutdoorUnit

Dimensions

Service Manual

Outdoor Unit

Product Specifications

Product Specifications

12Multi type Air Conditioner

B-DMH18DB-1

Product Specifications

Service Manual

Indoor Unit

Installation

Installation

InstallationParts

InstallationTools

Indoor unit

Select the best location

Installation

Rooftop Installations

Multi Piping Type

Piping length and elevation

16Multi type Air Conditioner

Installation

Installation

Fixing Installation Plate

Service Manual

18Multi type Air Conditioner

Flaring Work and Connection of Piping

Flaringwork

Flaring Work and Connection of Piping

Flaring Work and Connection of Piping

Connecting the Piping

For right rear piping

Service Manual

Flaring Work and Connection of Piping

20Multi type Air Conditioner

Service Manual

For left rear piping

Flaring Work and Connection of Piping

Indoor unit installation

22Multi type Air Conditioner

Flaring Work and Connection of Piping

HOW TO MOUNT ONTO A WALL HOW TO INSERT BATTERIES

REMOTE CONTROL PREPARATIONOPTIONAL

Flaring Work and Connection of Piping

Flaring Work and Connection of Piping

24Multi type Air Conditioner

Outdoor

Line voltage 208~230V

Connectthe cabletotheIndoorunit

Service Manual

Flaring Work and Connection of Piping

26Multi type Air Conditioner

Connectthe cabletotheOutdoor unit

Every wire must be connected firmly

How to connect wiring to the terminals

Connectionmethod ofthe connectingcableExample

Service Manual

28Multi type Air Conditioner

Connectthecable totheindoorunit

rating on the unit rating plate

Drain piping

Checkingthedrainage

Service Manual

To check the drainage

30Multi type Air Conditioner

Formingthe piping

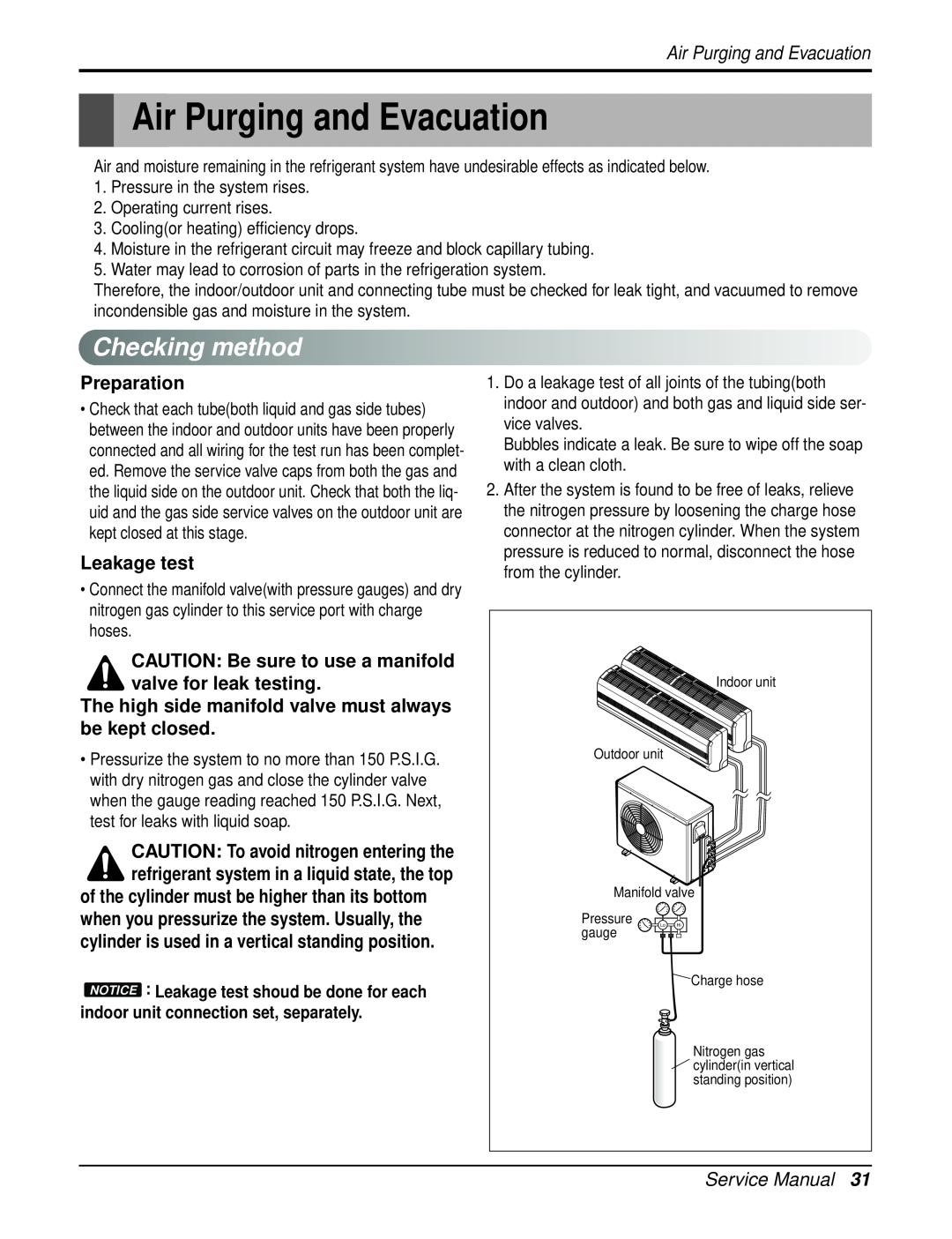

Air Purging and Evacuation

Service Manual

Air Purging and Evacuation

Checkingmethod

Finishing the job

Evacuation

32Multi type Air Conditioner

Repeat evacuation procedure for each indoor unit

Charging

Charging

Important:Unit is critically charge

Prepare remote control

Test Running

Test Running

34Multi type Air Conditioner

Operation

Operation

Functionofcontrol

1. MAIN UNIT FUNCTION

Fuzzy Operation

36Multi type Air Conditioner

Operation

Defrost ControlHeating

Operation

On-TimerOperation

Off-TimerOperation

Service Manual

Operation

38Multi type Air Conditioner

Off-Timer = On-TimerOperation

Sleep Timer Operation

Buzzer Sounding Operation

Service Manual

Operation

Forced Operation

Time Delay Safety Control

FunctionofIndoorUnit

40Multi type Air Conditioner

Operation ON/OFF by Remote controller

Operating Step

FunctionofOutdoor Unit

Service Manual

Operation

7ON/OFF TIMER BUTTONS

RemoteControlOperation

42Multi type Air Conditioner

SETTING BUTTONS

To remove the Grille from the Chassis

Disassembly

Disassembly

Indoor Unit

3.To remove the Discharge Grille

44Multi type Air Conditioner

Disassembly

2. To remove the Control Box

6.To remove the Cross-FlowFan

Service Manual

Disassembly

5.To remove the Motor Cover

1.Indoor Unit

Schematic Diagram

Schematic Diagram

ElectronicControlDevice

Schematic Diagram

2. Outdoor Unit

TMP87CM41F

Schematic Diagram

48 Multi type Air Conditioner

Service Manual

Wiring Diagram

1. Room Type Indoor Unit 2. Outdoor Unit

Schematic Diagram

• BOTTOM VIEW

ComponentsLocations

1. Indoor Unit

•TOP VIEW

2. Display ASSEMBLY 1 Split Type 6871A20682A

Schematic Diagram

1 Component side

3. Outdoor Unit

52Multi type Air Conditioner

Schematic Diagram

2 Solder side

Schematic Diagram

54Multi type Air Conditioner

Troubleshooting Guide

RefrigerationCycleDiagram

Troubleshooting Guide

Troubleshooting Guide

Indoor Error

Outdoor Error

Self-diagnosisFunction

Troubleshooting Guide

CycleTroubleshooting Guide

Trouble analysis

56Multi type Air Conditioner

Troubleshooting Guide

ElectronicPartsTroubleshooting Guide

Trouble

The Product doesn’t operate at all

Trouble

Product doesnt operate with the remote controller

58Multi type Air Conditioner

Troubleshooting Guide

Trouble

The Compressor/Outdoor Fan are dont operate

Troubleshooting Guide

Service Manual

Troubleshooting Guide

Trouble 4 When indoor Fan does not operate

When indoor Fan does not operate

60Multi type Air Conditioner

Service Manual

Trouble 5 When the louver does not operate

When Vertical Louver does not operate

Troubleshooting Guide

Trouble Shooting

ErrorCode

62Multi type Air Conditioner

Troubleshooting Guide

Title

Troubleshooting Guide

Power input AC 230V.Outdoor, Indoor

• The connecting wires are misconnected

Cause of error

64Multi type Air Conditioner

Troubleshooting Guide

Error

Title

Service Manual

Troubleshooting Guide

Cause of error

2-wayValve Liguid Side

2-way, 3-wayValve

2-way, 3-wayValve

66Multi type Air Conditioner

2.Operate the unit for 10 to 15 minutes

1 Pumping down

Service Manual

2-way, 3-wayValve

2-way, 3-wayValve

2 Evacuation

68Multi type Air Conditioner

7.Mount the valve caps and the service port caps

After Evacuation

3 Gas Charging

Service Manual

2-way, 3-wayValve

05/15/07

HEAT CONTROLLER, INC

1900 WELLWORTH AVENUE • JACKSON, MICHIGAN

THE QUALITY LEADER IN CONDITIONING AIR