PRO3 Side Mount Packaged Refrigeration System

Electrical Connection

1.Refer to all local codes for proper connection.

2.A

3.Wire will be brought into the electrical box through the bottom of the electrical box and connected to the top of the contactor.

Refrigeration Sequence of Operation

1.Power is provided to the temperature control, compressor contactor and cooler evaporator fans.

2.The temperature controller closes and energizes the compressor contactor, starting the compressor, evaporator and condenser fan(s).

3.When the system reaches the desired box temperature, the temperature control will

4.When the fixture temperature rises above the set point

and minimum

Coolers: Air-defrost Operation

Air defrost units are

For programming information see pages 7-16.

Cooler with Electric Defrost and Freezer Temperature/Defrost Control

PRO3 packaged refrigeration system cooler with electric defrost and freezer units come factory equipped with an electronic temperature/ defrost control.

For programming information see pages

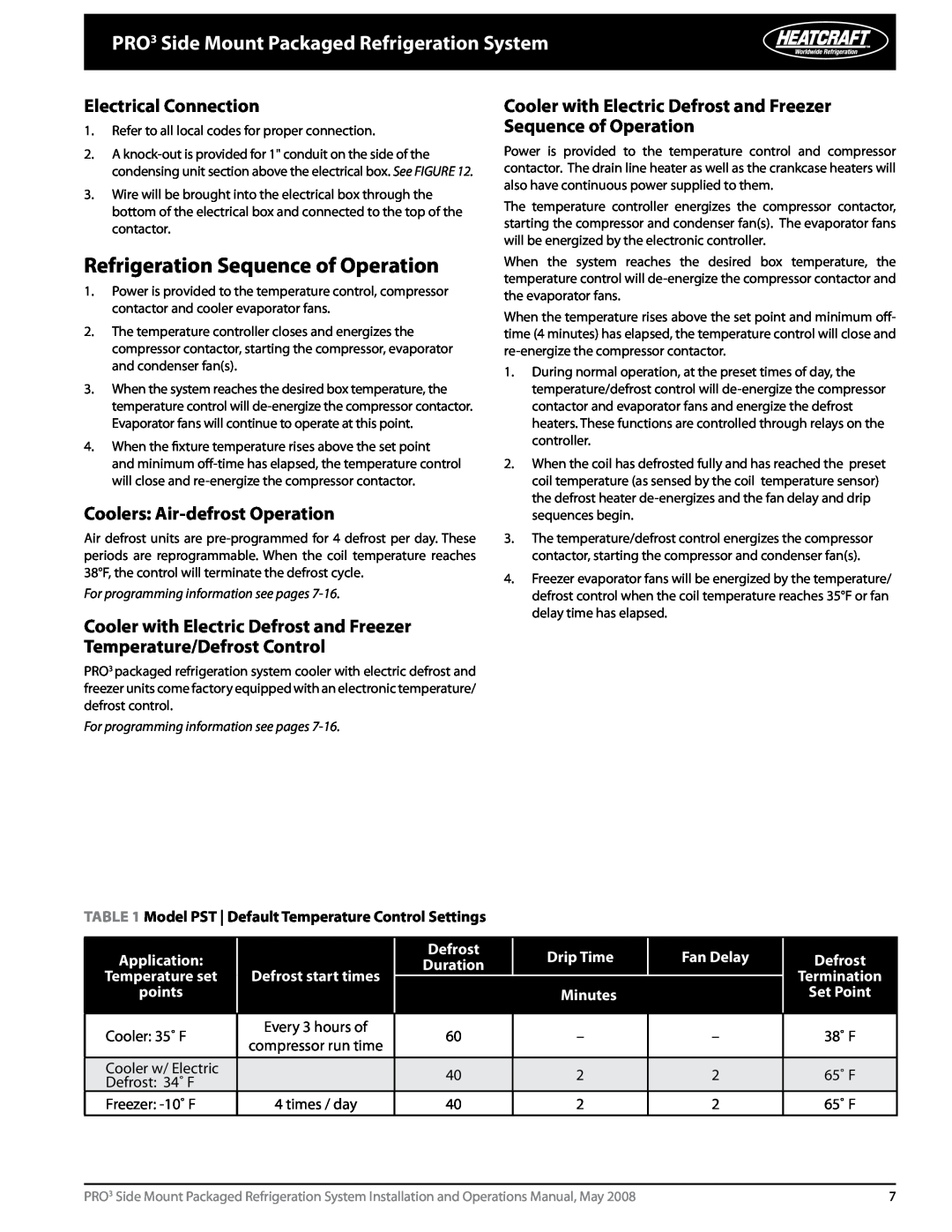

Table 1 Model PST Default Temperature Control Settings

Cooler with Electric Defrost and Freezer Sequence of Operation

Power is provided to the temperature control and compressor contactor. The drain line heater as well as the crankcase heaters will also have continuous power supplied to them.

The temperature controller energizes the compressor contactor, starting the compressor and condenser fan(s). The evaporator fans will be energized by the electronic controller.

When the system reaches the desired box temperature, the temperature control will

When the temperature rises above the set point and minimum off- time (4 minutes) has elapsed, the temperature control will close and

1.During normal operation, at the preset times of day, the temperature/defrost control will

2.When the coil has defrosted fully and has reached the preset coil temperature (as sensed by the coil temperature sensor) the defrost heater

3.The temperature/defrost control energizes the compressor contactor, starting the compressor and condenser fan(s).

4.Freezer evaporator fans will be energized by the temperature/ defrost control when the coil temperature reaches 35°F or fan delay time has elapsed.

Application:

Temperature set

points

Defrost start times

Defrost | Drip Time | Fan Delay | |

Duration | |||

|

| ||

| Minutes |

|

Defrost

Termination

Set Point

Cooler: 35˚ F | Every 3 hours of | 60 | – | – | 38˚ F | |

compressor run time | ||||||

|

|

|

|

| ||

|

|

|

|

|

| |

Cooler w/ Electric |

| 40 | 2 | 2 | 65˚ F | |

Defrost: 34˚ F |

| |||||

|

|

|

|

| ||

Freezer: | 4 times / day | 40 | 2 | 2 | 65˚ F |

PRO3 Side Mount Packaged Refrigeration System Installation and Operations Manual, May 2008 | 7 |