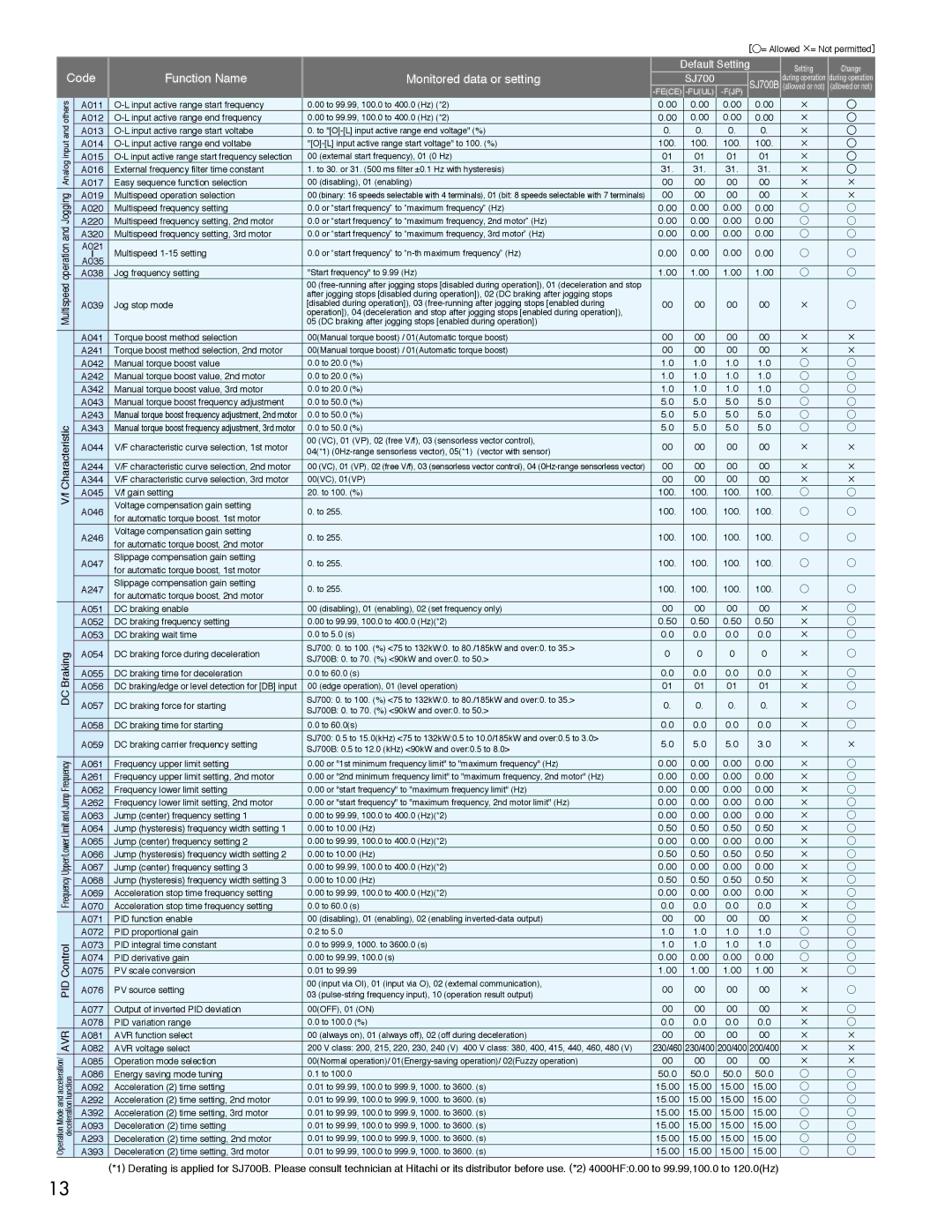

| | | | | | | | [◯= Allowed×= Not permitted | | ] |

| | | | | | | | |

Function Name | | Monitored data or setting | | | Default Setting | | | Setting | | Change |

| | | | SJ700 | | | | | | during operation during operation |

| | | | -FE(CE) -FU(UL) -F(JP) SJ700B | | (allowed or not) | | (allowed or not) |

O-L input active range start frequency | | 0.00 to 99.99, 100.0 to 400.0 (Hz) (*2) | | 0.00 | | 0.00 | | 0.00 | | 0.00 | | × | | ◯ |

| | | | | | |

O-L input active range end frequency | | 0.00 to 99.99, 100.0 to 400.0 (Hz) (*2) | | 0.00 | | 0.00 | | 0.00 | | 0.00 | | × | | ◯ |

O-L input active range start voltabe | | 0. to "[O]-[L] input active range end voltage" (%) | | 0. | | 0. | | 0. | | 0. | | × | | ◯ |

O-L input active range end voltabe | | "[O]-[L] input active range start voltage" to 100. (%) | | 100. | | 100. | | 100. | | 100. | | × | | ◯ |

O-L input active range start frequency selection | | 00 (external start frequency), 01 (0 Hz) | | 01 | | 01 | | 01 | | 01 | | × | | ◯ |

External frequency filter time constant | | 1. to 30. or 31. (500 ms filter ±0.1 Hz with hysteresis) | | 31. | | 31. | | 31. | | 31. | | × | | ◯ |

Easy sequence function selection | | 00 (disabling), 01 (enabling) | | 00 | | 00 | | 00 | | 00 | | × | | × | | |

Multispeed operation selection | | 00 (binary: 16 speeds selectable with 4 terminals), 01 (bit: 8 speeds selectable with 7 terminals) | | 00 | | 00 | | 00 | | 00 | | × | | × | | |

Multispeed frequency setting | | 0.0 or “start frequency” to “maximum frequency” (Hz) | | 0.00 | | 0.00 | | 0.00 | | 0.00 | | ○ | | ○ |

Multispeed frequency setting, 2nd motor | | 0.0 or “start frequency” to “maximum frequency, 2nd motor” (Hz) | | 0.00 | | 0.00 | | 0.00 | | 0.00 | | ○ | | ○ |

Multispeed frequency setting, 3rd motor | | 0.0 or “start frequency” to “maximum frequency, 3rd motor” (Hz) | | 0.00 | | 0.00 | | 0.00 | | 0.00 | | ○ | | ○ |

Multispeed 1-15 setting | | 0.0 or “start frequency” to “n-th maximum frequency” (Hz) | | 0.00 | | 0.00 | | 0.00 | | 0.00 | | ○ | | ○ |

Jog frequency setting | | "Start frequency" to 9.99 (Hz) | | 1.00 | | 1.00 | | 1.00 | | 1.00 | | ○ | | ○ |

| | 00 (free-running after jogging stops [disabled during operation]), 01 (deceleration and stop | | | | | | | | | | | | | | |

Jog stop mode | | after jogging stops [disabled during operation]), 02 (DC braking after jogging stops | | 00 | | 00 | | 00 | | 00 | | × | | ○ |

| [disabled during operation]), 03 (free-running after jogging stops [enabled during | | | | | | |

| | operation]), 04 (deceleration and stop after jogging stops [enabled during operation]), | | | | | | | | | | | | | | |

| | 05 (DC braking after jogging stops [enabled during operation]) | | | | | | | | | | | | | | |

Torque boost method selection | | 00(Manual torque boost) / 01(Automatic torque boost) | | 00 | | 00 | | 00 | | 00 | | × | | × | | |

Torque boost method selection, 2nd motor | | 00(Manual torque boost) / 01(Automatic torque boost) | | 00 | | 00 | | 00 | | 00 | | × | | × | | |

Manual torque boost value | | 0.0 to 20.0 (%) | | 1.0 | | 1.0 | | 1.0 | | 1.0 | | ○ | | ○ |

Manual torque boost value, 2nd motor | | 0.0 to 20.0 (%) | | 1.0 | | 1.0 | | 1.0 | | 1.0 | | ○ | | ○ |

Manual torque boost value, 3rd motor | | 0.0 to 20.0 (%) | | 1.0 | | 1.0 | | 1.0 | | 1.0 | | ○ | | ○ |

Manual torque boost frequency adjustment | | 0.0 to 50.0 (%) | | 5.0 | | 5.0 | | 5.0 | | 5.0 | | ○ | | ○ |

Manual torque boost frequency adjustment, 2nd motor | | 0.0 to 50.0 (%) | | 5.0 | | 5.0 | | 5.0 | | 5.0 | | ○ | | ○ |

Manual torque boost frequency adjustment, 3rd motor | | 0.0 to 50.0 (%) | | 5.0 | | 5.0 | | 5.0 | | 5.0 | | ○ | | ○ |

V/F characteristic curve selection, 1st motor | | 00 (VC), 01 (VP), 02 (free V/f), 03 (sensorless vector control), | | 00 | | 00 | | 00 | | 00 | | × | | × | | |

| 04(*1) (0Hz-range sensorless vector), 05(*1) (vector with sensor) | | | | | | | | |

| | | | | | | | | | | × | | × | | |

V/F characteristic curve selection, 2nd motor | | 00 (VC), 01 (VP), 02 (free V/f), 03 (sensorless vector control), 04 (0Hz-range sensorless vector) | | 00 | | 00 | | 00 | | 00 | | | | |

V/F characteristic curve selection, 3rd motor | | 00(VC), 01(VP) | | 00 | | 00 | | 00 | | 00 | | × | | × | | |

V/f gain setting | | 20. to 100. (%) | | 100. | | 100. | | 100. | | 100. | | ○ | | ○ |

Voltage compensation gain setting | | 0. to 255. | | 100. | | 100. | | 100. | | 100. | | ○ | | ○ |

for automatic torque boost. 1st motor | | | | | | | |

| | | | | | | | | | | | | | | |

Voltage compensation gain setting | | 0. to 255. | | 100. | | 100. | | 100. | | 100. | | ○ | | ○ |

for automatic torque boost, 2nd motor | | | | | | | |

| | | | | | | | | | | | | | | |

Slippage compensation gain setting | | 0. to 255. | | 100. | | 100. | | 100. | | 100. | | ○ | | ○ |

for automatic torque boost, 1st motor | | | | | | | |

| | | | | | | | | | | | | | | |

Slippage compensation gain setting | | 0. to 255. | | 100. | | 100. | | 100. | | 100. | | ○ | | ○ |

for automatic torque boost, 2nd motor | | | | | | | |

| | | 00 | | 00 | | 00 | | 00 | | × | | ○ |

DC braking enable | | 00 (disabling), 01 (enabling), 02 (set frequency only) | | | | | | |

DC braking frequency setting | | 0.00 to 99.99, 100.0 to 400.0 (Hz)(*2) | | 0.50 | | 0.50 | | 0.50 | | 0.50 | | × | | ○ |

DC braking wait time | | 0.0 to 5.0 (s) | | 0.0 | | 0.0 | | 0.0 | | 0.0 | | × | | ○ |

DC braking force during deceleration | | SJ700: 0. to 100. (%) <75 to 132kW:0. to 80./185kW and over:0. to 35.> | | 0 | | 0 | | 0 | | 0 | | × | | ○ |

| SJ700B: 0. to 70. (%) <90kW and over:0. to 50.> | | | | | | |

| | | 0.0 | | 0.0 | | 0.0 | | 0.0 | | × | | ○ |

DC braking time for deceleration | | 0.0 to 60.0 (s) | | | | | | |

DC braking/edge or level detection for [DB] input | | 00 (edge operation), 01 (level operation) | | 01 | | 01 | | 01 | | 01 | | × | | ○ |

DC braking force for starting | | SJ700: 0. to 100. (%) <75 to 132kW:0. to 80./185kW and over:0. to 35.> | | 0. | | 0. | | 0. | | 0. | | × | | ○ |

| SJ700B: 0. to 70. (%) <90kW and over:0. to 50.> | | | | | | |

| | | 0.0 | | 0.0 | | 0.0 | | 0.0 | | × | | ○ |

DC braking time for starting | | 0.0 to 60.0(s) | | | | | | |

DC braking carrier frequency setting | | SJ700: 0.5 to 15.0(kHz) <75 to 132kW:0.5 to 10.0/185kW and over:0.5 to 3.0> | | 5.0 | | 5.0 | | 5.0 | | 3.0 | | × | | × | | |

| SJ700B: 0.5 to 12.0 (kHz) <90kW and over:0.5 to 8.0> | | | | | | | | |

| | | 0.00 | | 0.00 | | 0.00 | | 0.00 | | × | | ○ |

Frequency upper limit setting | | 0.00 or "1st minimum frequency limit" to "maximum frequency" (Hz) | | | | | | |

Frequency upper limit setting, 2nd motor | | 0.00 or "2nd minimum frequency limit" to "maximum frequency, 2nd motor" (Hz) | | 0.00 | | 0.00 | | 0.00 | | 0.00 | | × | | ○ |

Frequency lower limit setting | | 0.00 or "start frequency" to "maximum frequency limit" (Hz) | | 0.00 | | 0.00 | | 0.00 | | 0.00 | | × | | ○ |

Frequency lower limit setting, 2nd motor | | 0.00 or "start frequency" to "maximum frequency, 2nd motor limit" (Hz) | | 0.00 | | 0.00 | | 0.00 | | 0.00 | | × | | ○ |

Jump (center) frequency setting 1 | | 0.00 to 99.99, 100.0 to 400.0 (Hz)(*2) | | 0.00 | | 0.00 | | 0.00 | | 0.00 | | × | | ○ |

Jump (hysteresis) frequency width setting 1 | | 0.00 to 10.00 (Hz) | | 0.50 | | 0.50 | | 0.50 | | 0.50 | | × | | ○ |

Jump (center) frequency setting 2 | | 0.00 to 99.99, 100.0 to 400.0 (Hz)(*2) | | 0.00 | | 0.00 | | 0.00 | | 0.00 | | × | | ○ |

Jump (hysteresis) frequency width setting 2 | | 0.00 to 10.00 (Hz) | | 0.50 | | 0.50 | | 0.50 | | 0.50 | | × | | ○ |

Jump (center) frequency setting 3 | | 0.00 to 99.99, 100.0 to 400.0 (Hz)(*2) | | 0.00 | | 0.00 | | 0.00 | | 0.00 | | × | | ○ |

Jump (hysteresis) frequency width setting 3 | | 0.00 to 10.00 (Hz) | | 0.50 | | 0.50 | | 0.50 | | 0.50 | | × | | ○ |

Acceleration stop time frequency setting | | 0.00 to 99.99, 100.0 to 400.0 (Hz)(*2) | | 0.00 | | 0.00 | | 0.00 | | 0.00 | | × | | ○ |

Acceleration stop time frequency setting | | 0.0 to 60.0 (s) | | 0.0 | | 0.0 | | 0.0 | | 0.0 | | × | | ○ |

PID function enable | | 00 (disabling), 01 (enabling), 02 (enabling inverted-data output) | | 00 | | 00 | | 00 | | 00 | | × | | ○ |

PID proportional gain | | 0.2 to 5.0 | | 1.0 | | 1.0 | | 1.0 | | 1.0 | | ○ | | ○ |

PID integral time constant | | 0.0 to 999.9, 1000. to 3600.0 (s) | | 1.0 | | 1.0 | | 1.0 | | 1.0 | | ○ | | ○ |

PID derivative gain | | 0.00 to 99.99, 100.0 (s) | | 0.00 | | 0.00 | | 0.00 | | 0.00 | | ○ | | ○ |

PV scale conversion | | 0.01 to 99.99 | | 1.00 | | 1.00 | | 1.00 | | 1.00 | | × | | ○ |

PV source setting | | 00 (input via OI), 01 (input via O), 02 (external communication), | | 00 | | 00 | | 00 | | 00 | | × | | ○ |

| 03 (pulse-string frequency input), 10 (operation result output) | | | | | | |

| | | 00 | | 00 | | 00 | | 00 | | × | | ○ |

Output of inverted PID deviation | | 00(OFF), 01 (ON) | | | | | | |

PID variation range | | 0.0 to 100.0 (%) | | 0.0 | | 0.0 | | 0.0 | | 0.0 | | × | | ○ |

AVR function select | | 00 (always on), 01 (always off), 02 (off during deceleration) | | 00 | | 00 | | 00 | | 00 | | × | | × | | |

AVR voltage select | | 200 V class: 200, 215, 220, 230, 240 (V) 400 V class: 380, 400, 415, 440, 460, 480 (V) | | 230/460 | 230/400 | | 200/400 | | 200/400 | | × | | × | | |

Operation mode selection | | 00(Normal operation)/ 01(Energy-saving operation)/ 02(Fuzzy operation) | | 00 | | 00 | | 00 | | 00 | | × | | × | | |

Energy saving mode tuning | | 0.1 to 100.0 | | 50.0 | | 50.0 | | 50.0 | | 50.0 | | ○ | | ○ |

Acceleration (2) time setting | | 0.01 to 99.99, 100.0 to 999.9, 1000. to 3600. (s) | | 15.00 | | 15.00 | | 15.00 | | 15.00 | | ○ | | ○ |

Acceleration (2) time setting, 2nd motor | | 0.01 to 99.99, 100.0 to 999.9, 1000. to 3600. (s) | | 15.00 | | 15.00 | | 15.00 | | 15.00 | | ○ | | ○ |

Acceleration (2) time setting, 3rd motor | | 0.01 to 99.99, 100.0 to 999.9, 1000. to 3600. (s) | | 15.00 | | 15.00 | | 15.00 | | 15.00 | | ○ | | ○ |

Deceleration (2) time setting | | 0.01 to 99.99, 100.0 to 999.9, 1000. to 3600. (s) | | 15.00 | | 15.00 | | 15.00 | | 15.00 | | ○ | | ○ |

Deceleration (2) time setting, 2nd motor | | 0.01 to 99.99, 100.0 to 999.9, 1000. to 3600. (s) | | 15.00 | | 15.00 | | 15.00 | | 15.00 | | ○ | | ○ |

Deceleration (2) time setting, 3rd motor | | 0.01 to 99.99, 100.0 to 999.9, 1000. to 3600. (s) | | 15.00 | | 15.00 | | 15.00 | | 15.00 | | ○ | | ○ |