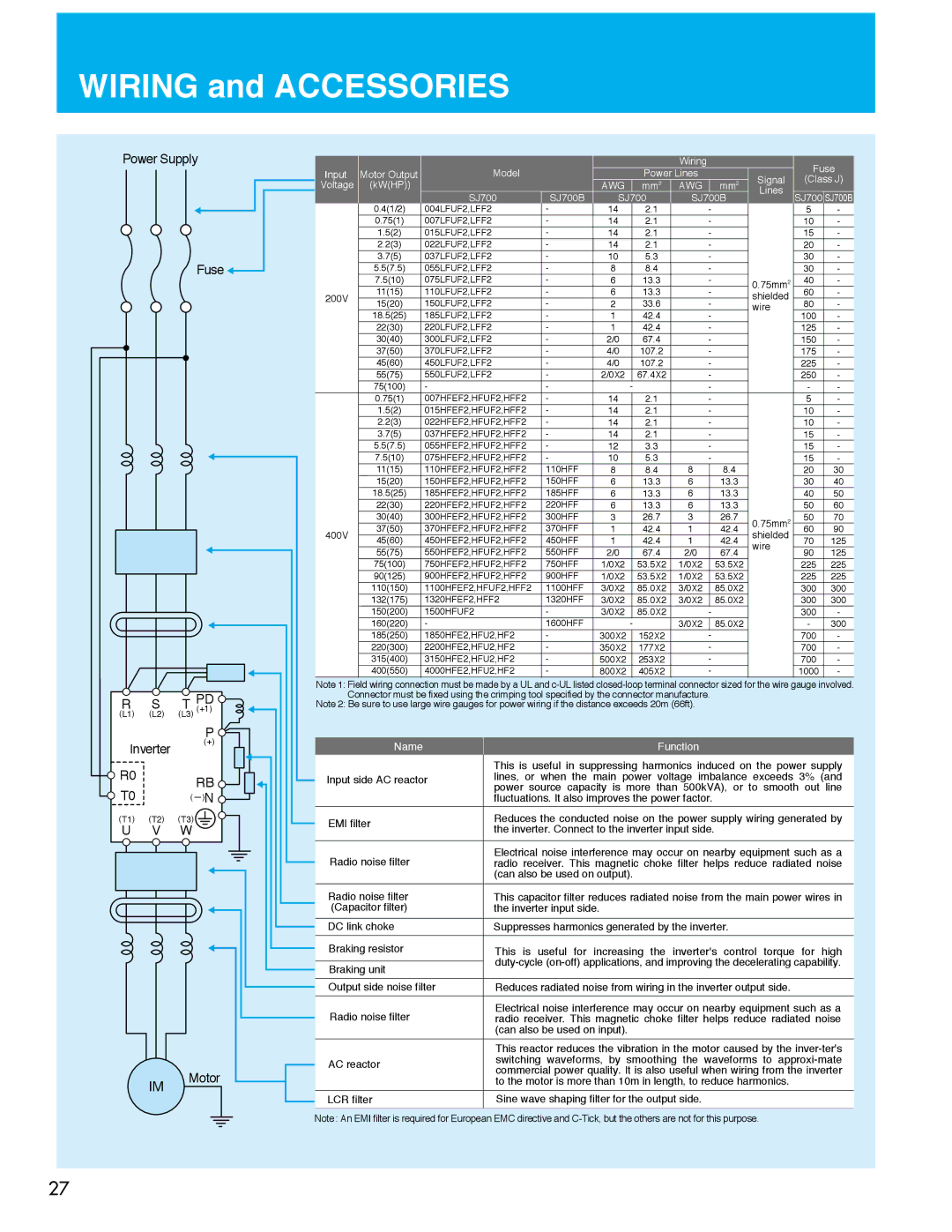

SJ700B, SJ700 specifications

The Hitachi SJ700 and SJ700B series are renowned variable frequency drives (VFDs) that represent a significant advancement in motor control technology. Designed for industrial applications, these drives offer a versatile solution for managing motor speed, torque, and efficiency in a variety of settings.One of the main features of the SJ700 and SJ700B series is their compact design. This allows for easy installation and integration into existing systems, which is crucial for minimizing downtime during upgrades or replacements. The drives support multiple mounting orientations, facilitating applications with space constraints.

Another standout characteristic is their advanced control algorithms. The SJ700 series uses vector control technology, which optimizes the performance of both AC and induction motors. This ensures high precision in speed and torque control, making it suitable for processes that require fine adjustments. The drives also feature automatic tuning capabilities, which allow for quick commissioning while minimizing the need for extensive parameter adjustments.

The SJ700 and SJ700B series are designed with energy efficiency in mind. They utilize advanced regenerative braking technology that recovers energy, reducing power consumption and improving overall system efficiency. Furthermore, these drives incorporate energy-saving features that optimize motor operation based on load requirements, contributing to a lower carbon footprint.

These drives come equipped with robust communication capabilities. They support various communication protocols such as Modbus, Profibus, and EtherCAT, making them easily integrable with modern automation systems. This flexibility allows for real-time monitoring and control, enhancing operational visibility and efficiency.

Reliability is another hallmark of the SJ700 series. Built with high-quality components, these drives exhibit excellent thermal management and protection against overvoltage, overload, and short circuits. The SJ700B variant boasts additional features such as enhanced fault diagnostics and improved environmental protection, making it suitable for more demanding applications.

In conclusion, the Hitachi SJ700 and SJ700B series variable frequency drives stand out in terms of compact design, advanced control technologies, energy efficiency, versatile communication options, and robust reliability. These features make them an ideal choice for a wide range of industrial applications, from manufacturing automation to HVAC systems, ensuring optimal performance and cost savings for users.