.A complete Parts List is available at www.HobartWelders.com

SECTION 5 − OPERATION

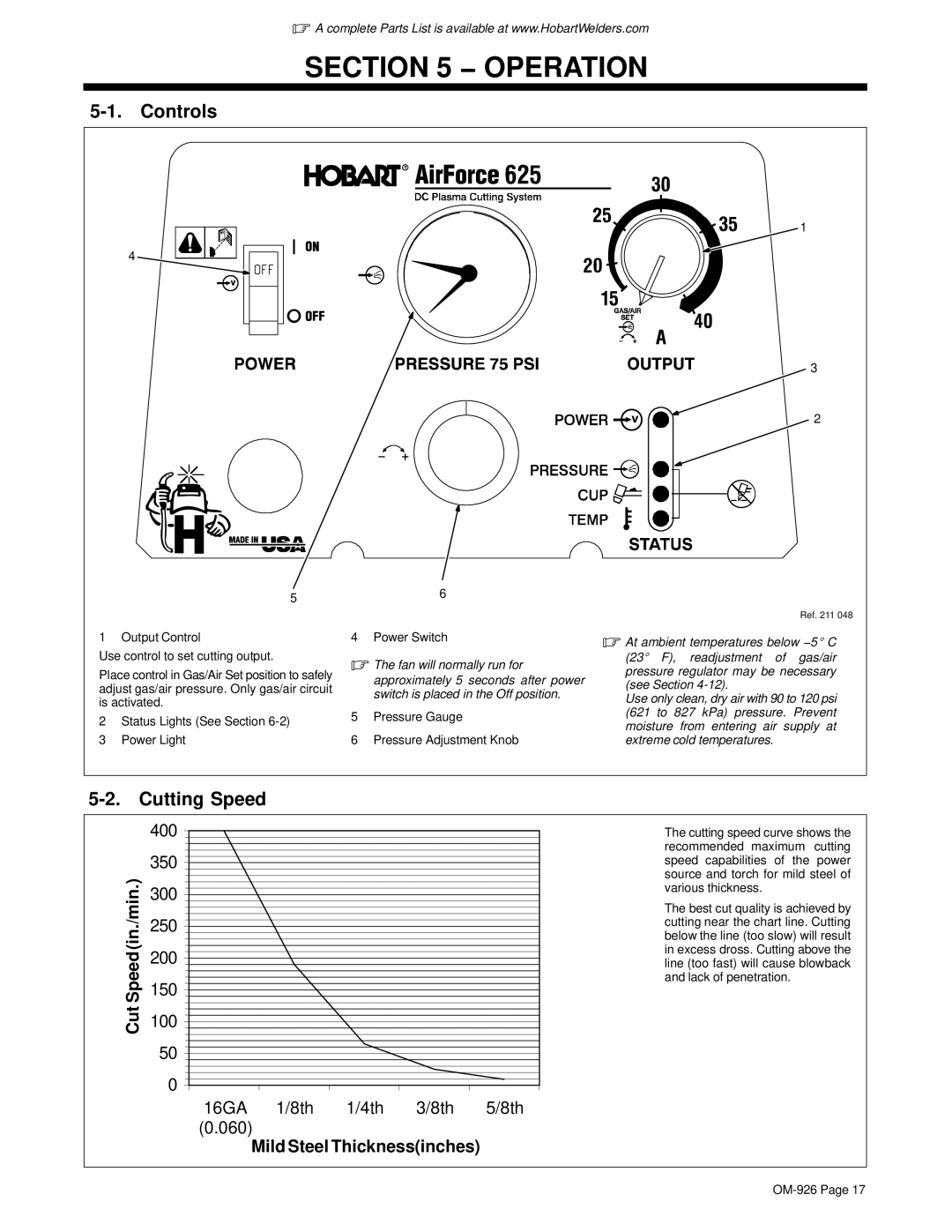

5-1. Controls

4

5

1 Output Control

Use control to set cutting output.

Place control in Gas/Air Set position to safely adjust gas/air pressure. Only gas/air circuit is activated.

2Status Lights (See Section

3Power Light

6

4 Power Switch

.The fan will normally run for approximately 5 seconds after power switch is placed in the Off position.

5Pressure Gauge

6Pressure Adjustment Knob

1

3

2

Ref. 211 048

.At ambient temperatures below −55 C (235 F), readjustment of gas/air pressure regulator may be necessary (see Section

Use only clean, dry air with 90 to 120 psi (621 to 827 kPa) pressure. Prevent moisture from entering air supply at extreme cold temperatures.

5-2. Cutting Speed

| 400 |

|

|

|

|

| 350 |

|

|

|

|

Speed(in./min.) | 300 |

|

|

|

|

250 |

|

|

|

| |

200 |

|

|

|

| |

150 |

|

|

|

| |

|

|

|

|

| |

Cut | 100 |

|

|

|

|

|

|

|

|

| |

| 50 |

|

|

|

|

| 0 |

|

|

|

|

| 16GA | 1/8th | 1/4th | 3/8th | 5/8th |

| (0.060) |

|

|

| |

|

| Mild Steel Thickness(inches) |

| ||

The cutting speed curve shows the recommended maximum cutting speed capabilities of the power source and torch for mild steel of various thickness.

The best cut quality is achieved by cutting near the chart line. Cutting below the line (too slow) will result in excess dross. Cutting above the line (too fast) will cause blowback and lack of penetration.