.A complete Parts List is available at www.HobartWelders.com

1

2

3

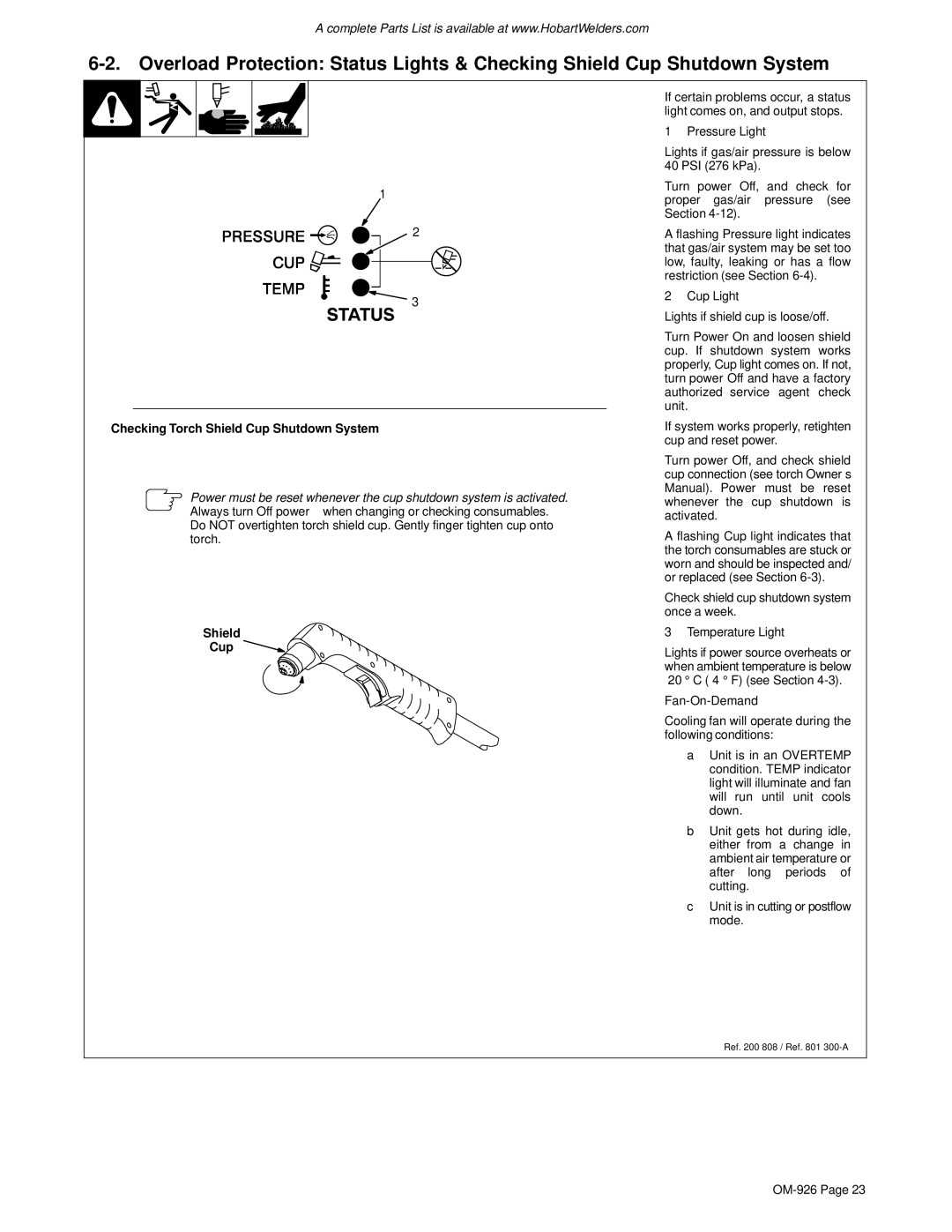

Checking Torch Shield Cup Shutdown System

Power must be reset whenever the cup shutdown system is activated.

Always turn Off power when changing or checking consumables. Do NOT overtighten torch shield cup. Gently finger tighten cup onto torch.

Shield

Cup

If certain problems occur, a status light comes on, and output stops.

1 Pressure Light

Lights if gas/air pressure is below 40 PSI (276 kPa).

Turn power Off, and check for proper gas/air pressure (see Section

A flashing Pressure light indicates that gas/air system may be set too low, faulty, leaking or has a flow restriction (see Section

2 Cup Light

Lights if shield cup is loose/off.

Turn Power On and loosen shield cup. If shutdown system works properly, Cup light comes on. If not, turn power Off and have a factory authorized service agent check unit.

If system works properly, retighten cup and reset power.

Turn power Off, and check shield cup connection (see torch Owner’s Manual). Power must be reset whenever the cup shutdown is activated.

A flashing Cup light indicates that the torch consumables are stuck or worn and should be inspected and/ or replaced (see Section

Check shield cup shutdown system once a week.

3 Temperature Light

Lights if power source overheats or when ambient temperature is below −20° C (−4° F) (see Section

Cooling fan will operate during the following conditions:

aUnit is in an OVERTEMP condition. TEMP indicator light will illuminate and fan will run until unit cools down.

bUnit gets hot during idle, either from a change in ambient air temperature or after long periods of cutting.

cUnit is in cutting or postflow mode.

Ref. 200 808 / Ref. 801