SECTION 4 – MAINTENANCE &TROUBLESHOOTING

4-1. Routine Maintenance

Y |

Disconnect power before maintaining.

.Maintain more often during severe conditions.

3 Months

Replace unreadable labels

Repair or replace cracked weld cable

Clean and tighten weld terminals

6 Months

Blow out or vacuum inside.

OR

Remove drive roll and carrier. Apply light coat of oil or grease to drive motor shaft.

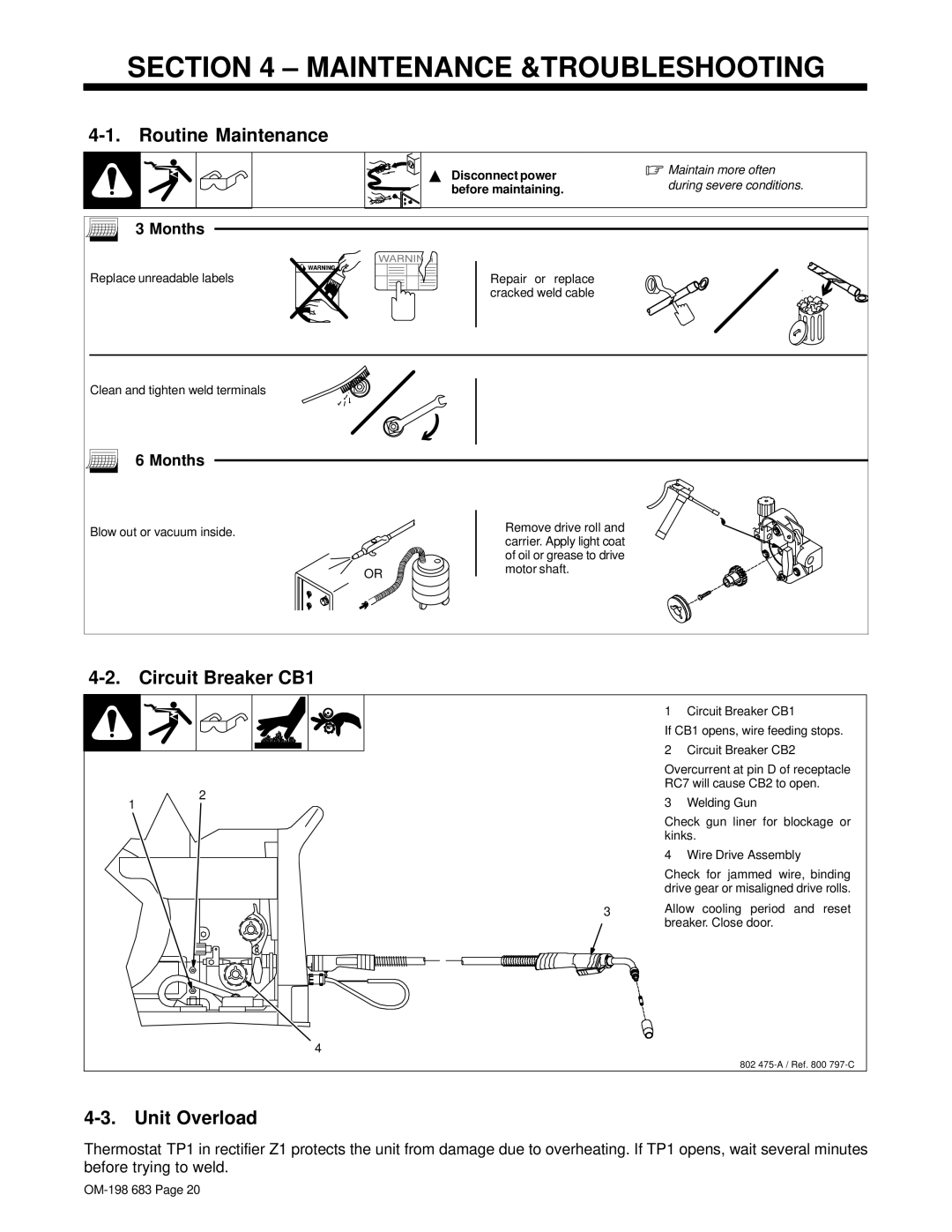

4-2. Circuit Breaker CB1

2

1

1 Circuit Breaker CB1

If CB1 opens, wire feeding stops.

2 Circuit Breaker CB2

Overcurrent at pin D of receptacle RC7 will cause CB2 to open.

3 Welding Gun

Check gun liner for blockage or kinks.

4 Wire Drive Assembly

Check for jammed wire, binding drive gear or misaligned drive rolls.

3Allow cooling period and reset breaker. Close door.

4

802

4-3. Unit Overload

Thermostat TP1 in rectifier Z1 protects the unit from damage due to overheating. If TP1 opens, wait several minutes before trying to weld.