MAINTENANCE

CLEANING THE SPARK ARRESTING SILENCER

The silencer is equipped with a spark arrester screen. A faulty spark arrester screen may create a fire hazard. Through normal use the screen becomes dirty and should be inspected weekly and cleaned as required. Always keep the silencer and spark arrester on your saw in good condition.

![]() WARNING

WARNING

Silencer surfaces are very hot during and after operation of the chainsaw. Keep all body parts away from the silencer. Serious burns may occur if contact is made with the silencer.

1.Allow the silencer to cool.

2.The spark arrester screen is retained by the deflector. Remove the nuts and screen retainer to access the spark arrester screen.

3.Replace the spark arrester screen if it is cracked or otherwise deteriorated.

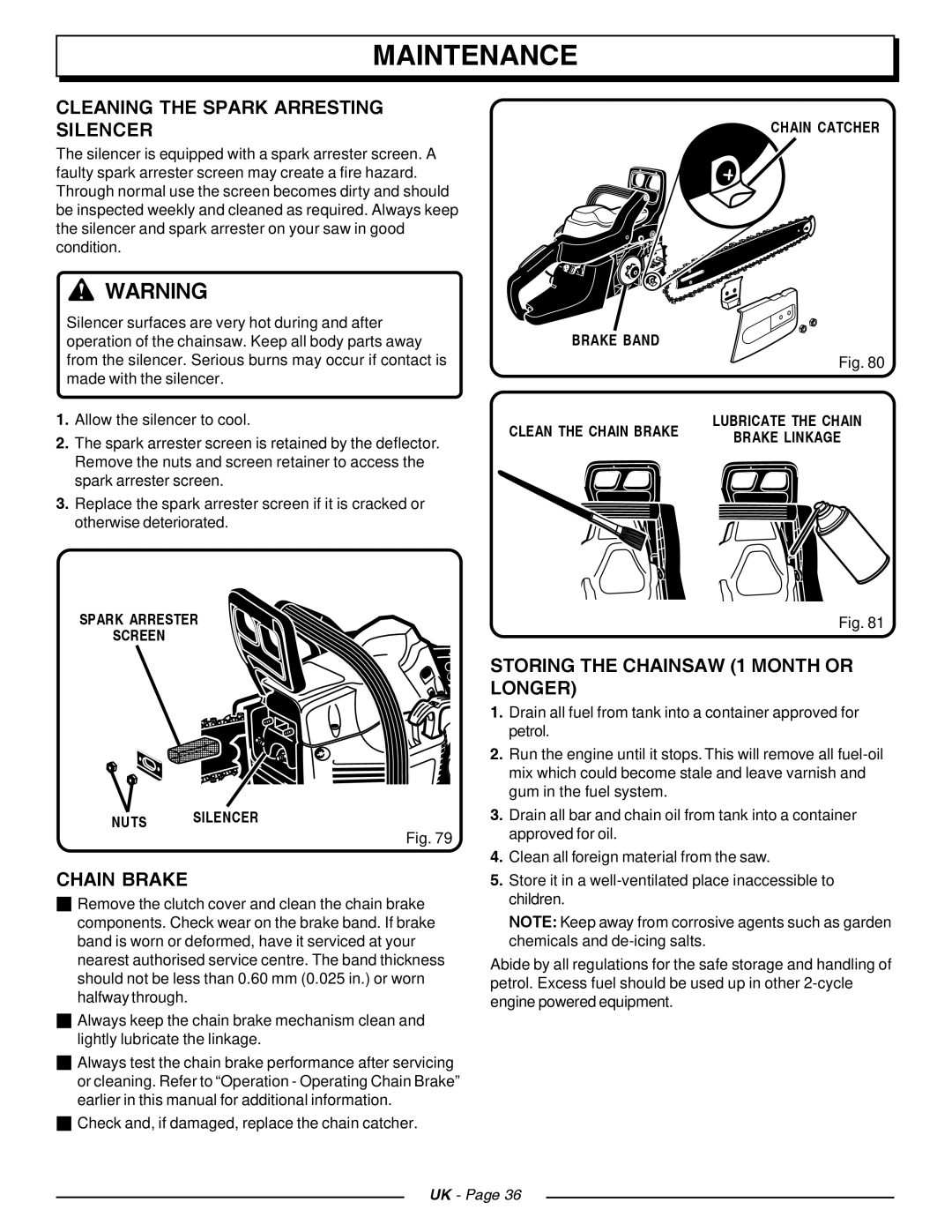

CHAIN CATCHER

BRAKE BAND

Fig. 80

CLEAN THE CHAIN BRAKE | LUBRICATE THE CHAIN | |

BRAKE LINKAGE | ||

|

SPARK ARRESTER

SCREEN

NUTS SILENCER

Fig. 79

CHAIN BRAKE

Remove the clutch cover and clean the chain brake components. Check wear on the brake band. If brake band is worn or deformed, have it serviced at your nearest authorised service centre. The band thickness should not be less than 0.60 mm (0.025 in.) or worn halfway through.

Always keep the chain brake mechanism clean and lightly lubricate the linkage.

Always test the chain brake performance after servicing or cleaning. Refer to “Operation - Operating Chain Brake” earlier in this manual for additional information.

Check and, if damaged, replace the chain catcher.

Fig. 81

STORING THE CHAINSAW (1 MONTH OR LONGER)

1.Drain all fuel from tank into a container approved for petrol.

2.Run the engine until it stops. This will remove all

3.Drain all bar and chain oil from tank into a container approved for oil.

4.Clean all foreign material from the saw.

5.Store it in a

NOTE: Keep away from corrosive agents such as garden chemicals and

Abide by all regulations for the safe storage and handling of petrol. Excess fuel should be used up in other

UK - Page 36