MAINTENANCE

GEARBOX MAINTENANCE

Read this complete section before starting any repair. Many steps are dependent on each other.

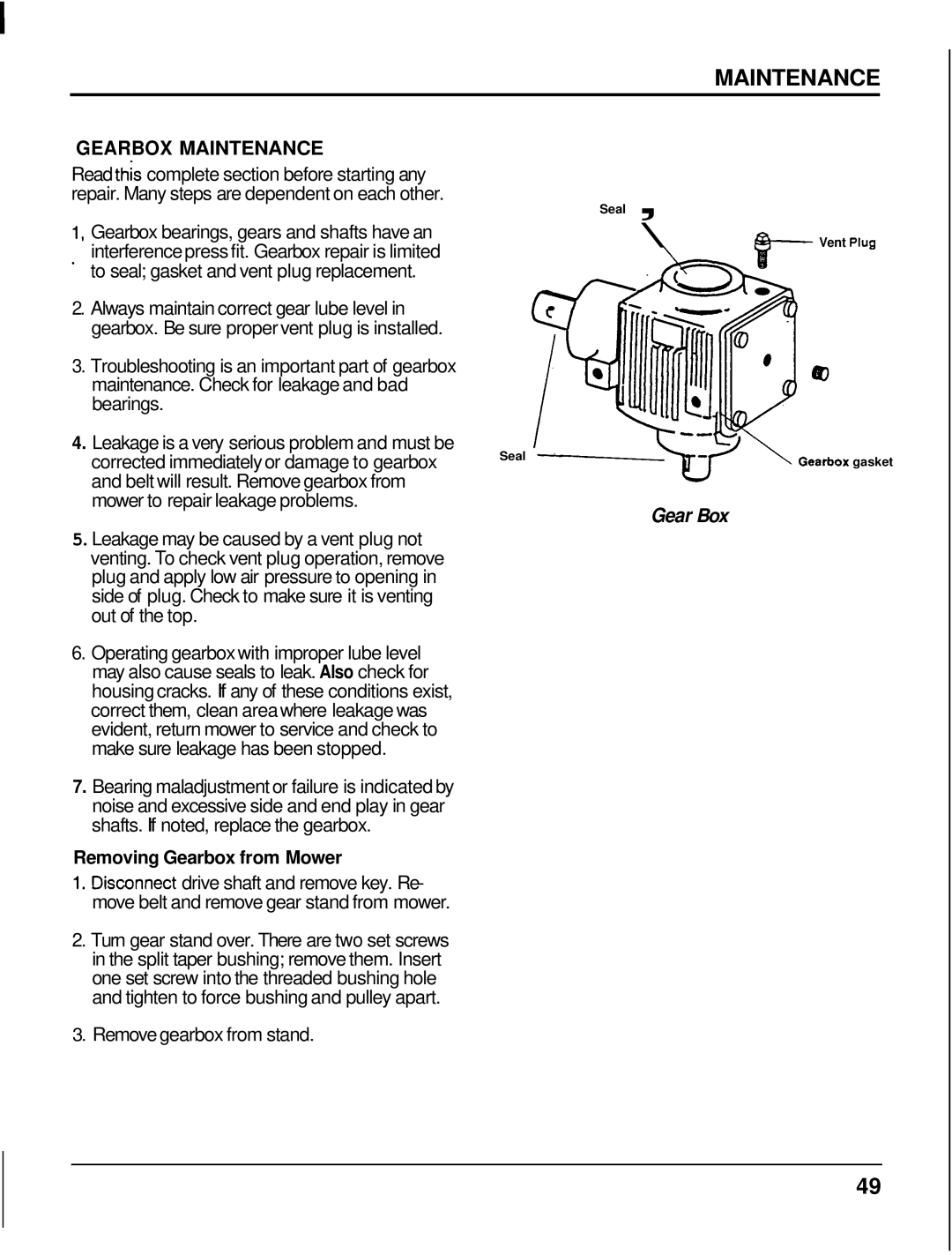

1, Gearbox bearings, gears and shafts have an interference press fit. Gearbox repair is limited to seal; gasket and vent plug replacement.

2.Always maintain correct gear lube level in gearbox. Be sure proper vent plug is installed.

3.Troubleshooting is an important part of gearbox maintenance. Check for leakage and bad bearings.

4.Leakage is a very serious problem and must be corrected immediately or damage to gearbox and belt will result. Remove gearbox from mower to repair leakage problems.

5.Leakage may be caused by a vent plug not venting. To check vent plug operation, remove plug and apply low air pressure to opening in side of plug. Check to make sure it is venting out of the top.

6.Operating gearbox with improper lube level may also cause seals to leak. Also check for housing cracks. If any of these conditions exist, correct them, clean area where leakage was evident, return mower to service and check to make sure leakage has been stopped.

7.Bearing maladjustment or failure is indicated by noise and excessive side and end play in gear shafts. If noted, replace the gearbox.

Removing Gearbox from Mower

1.Disconnect drive shaft and remove key. Re- move belt and remove gear stand from mower.

2.Turn gear stand over. There are two set screws in the split taper bushing; remove them. Insert one set screw into the threaded bushing hole and tighten to force bushing and pulley apart.

3.Remove gearbox from stand.

Seal ,

\ | &- Vent Plug |

Seal | u | gasket |

| ||

|

|

Gear Box

49