Spray Gun Terms (Cont.)

FLUID CONTROL KNOB – Used to con- trol the amount of paint being mixed with air.

PAINT TANK – An auxiliary pressurized paint reservoir that allows continuous spraying of large amounts of paint with- out stopping for refills as with a canister. It also allows using the spray gun at any angle or orientation.

General Safety

Information

CALIFORNIA PROPOSITION 65

You can create dust when you cut, sand, drill or grind materials such as wood,

paint, metal, concrete, cement, or other masonry. This dust often contains chemicals known to cause cancer, birth defects, or other reproductive harm. Wear protective gear.

This product or its power cord may con- tain chemicals known to the State of California to cause cancer and birth defects or other reproductive harm. Wash hands after handling.

This product or its power cord may con- tain chemicals known to the State of California to cause cancer and birth defects or other reproductive harm. Wash hands after handling.

GENERAL SAFETY INFORMATION

1. Read all manuals included with this product carefully.

MANUEL

Be thoroughly familiar with the controls and the proper use of the equipment.

2.Follow all local electrical and safety codes as well as in the United States, the National Electrical Codes (NEC) and Occupational Safety and Health Act (OSHA).

Use a face mask/respirator and protective clothing when spraying. Always spray in a

well ventilated area to prevent health and fire hazards. Refer to Material Safety Data Sheets (MSDS) of spray material for details.

Never spray closer than 25 feet to the compressor! If possible, locate compressor in separate

room. Never spray into the compressor, compressor controls or the motor.

3.Do not smoke or eat when spraying paint, insecticides, or other flam- mable substances.

Do not spray flammable materials in vicinity of open flame or near ignition sourc-

es. Motors, electrical equipment and controls can cause electrical arcs that will ignite a flammable gas or vapor. Never store flammable liquids or gases in the vicinity of the compressor.

4.When spraying and cleaning, always follow the instructions and safety precautions provided by the material manufacturer (Refer to MSDS).

Do not spray

acids, corrosive materials, toxic chemi- cals, fertilizers or pesticides. Using these materials could result in death or serious injury.

5.Keep visitors away and NEVER allow children or pets in the work area.

Never aim or

spray at yourself or anyone else or seri- ous injury could occur.

6.Always work in a clean environment. To avoid injury and damage to the workpiece, do not aim the spray gun at any dust or debris.

Do not use pressure that

exceeds the operating pressure

exceeds the operating pressure

of any of the parts (hoses, fit-

of any of the parts (hoses, fit-

tings, etc.) in the painting system.

Keep hose away

from sharp objects. Bursting air hoses may cause injury. Examine air hoses regularly and replace if damaged.

7.Always use a pressure regulator on the air supply to the spray gun.

Failure to install

appropriate water/oil removal equip- ment may result in damage to machin- ery or workpiece.

Preparation

1.Thoroughly mix the paint in accor- dance with the manufacturer’s instructions, adding thinner where necessary. Most materials will spray readily if thinned properly. Strain material through cheese cloth or a paint strainer. Test the consistency of the material by making a few strokes on a cardboard target. If material still appears too thick, add a small amount of thinner. THIN WITH CARE!!

2.Fill the canister about 3/4 full and start the air compressor.

3.Set up a piece of cardboard or other scrap material to use as a target and adjust for best spray pattern.

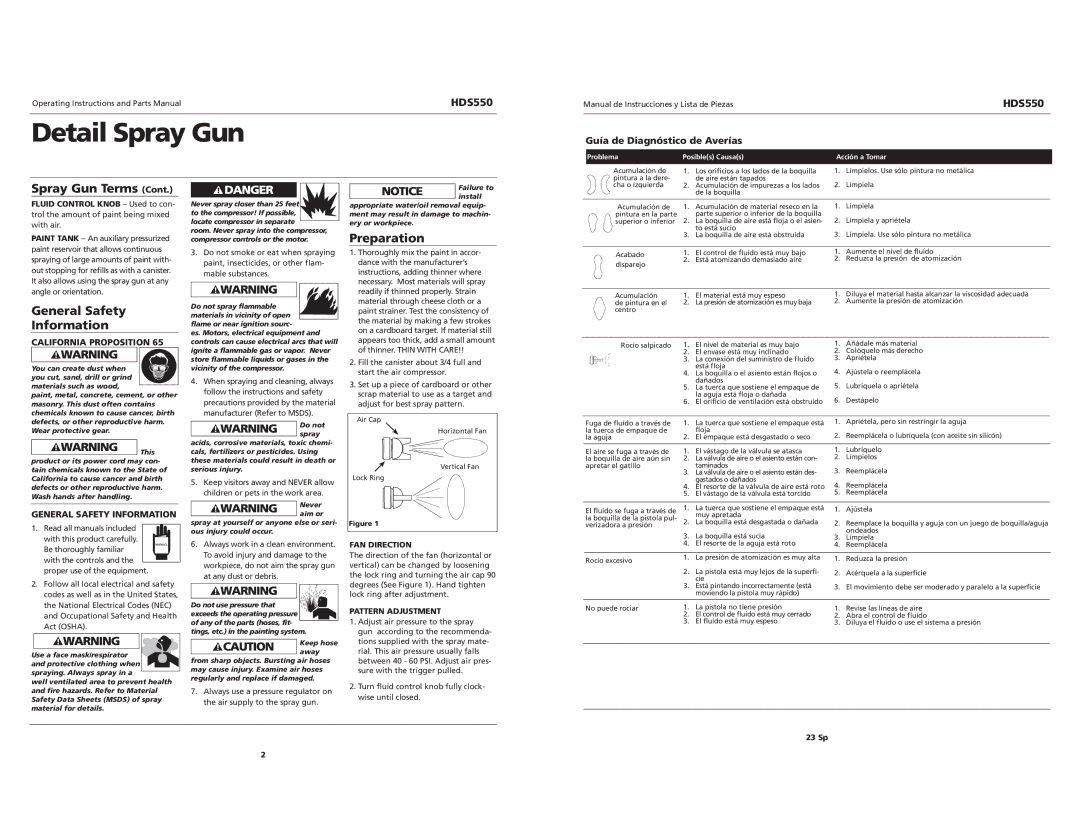

Air Cap

Horizontal Fan

Vertical Fan

Lock Ring

Figure 1

FAN DIRECTION

The direction of the fan (horizontal or vertical) can be changed by loosening the lock ring and turning the air cap 90 degrees (See Figure 1). Hand tighten lock ring after adjustment.

PATTERN ADJUSTMENT

1.Adjust air pressure to the spray gun according to the recommenda- tions supplied with the spray mate- rial. This air pressure usually falls between 40 - 60 PSI. Adjust air pres- sure with the trigger pulled.

2.Turn fluid control knob fully clock- wise until closed.

| | cha o izquierda | 2. | Acumulación de impurezas a los lados | 2. | Límpiela |

| | | | | | | | de la boquilla | | | |

| | | | | | | | | | |

| | | | | Acumulación de | 1. | Acumulación de material reseco en la | 1. | Límpiela |

| | | |

| | | | | pintura en la parte | | parte superior o inferior de la boquilla | 2. | Límpiela y apriétela |

| | | | | superior o inferior | 2. | La boquilla de aire está floja o el asien- |

| | | | | | | | to está sucio | 3. | Límpiela. Use sólo pintura no metálica |

| | | | | | | 3. | La boquilla de aire está obstruída |

| | | | | | | | | | | |

| | | | | | | | | | | |

| | | | | Acabado | 1. | El control de fluído está muy bajo | 1. | Aumente el nivel de fluído |

| | | | | 2. | Está atomizando demasiado aire | 2. | Reduzca la presión de atomización |

| | | | | disparejo |

| | | | | | | | | |

| | | | | | | | | | |

| | | | | | | | | | |

| | | | | Acumulación | 1. | El material está muy espeso | 1. | Diluya el material hasta alcanzar la viscosidad adecuada |

| | |

| | | | | de pintura en el | 2. | La presión de atomización es muy baja | 2. | Aumente la presión de atomización |

| | | | | centro | | | | | |

| | | | | | | | | | | |

| | | | | | | | | | | |

| | | | | | Rocío salpicado | 1. | El nivel de material es muy bajo | 1. | Añádale más material |

| | | | | |

| | | | | | | 2. | El envase está muy inclinado | 2. | Colóquelo más derecho |

| | | | | | | 3. | La conexión del suministro de fluído | 3. | Apriétela |

| | | | | | | | está floja | 4. | Ajústela o reemplácela |

| | | | | | | 4. | La boquilla o el asiento están flojos o |

| | | | | | | | dañados | 5. | Lubríquela o apriétela |

| | | | | | | |

| | | | | | | 5. | La tuerca que sostiene el empaque de |

| | | | | | | | la aguja está floja o dañada | 6. | Destápelo |

| | | | | | | 6. | El orificio de ventilación está obstruído |

| | | | | | | |

| | Fuga de fluído a través de | 1. | La tuerca que sostiene el empaque está | 1. | Apriétela, pero sin restringir la aguja |

| | la tuerca de empaque de | | floja | 2. | Reemplácela o lubríquela (con aceite sin silicón) |

| | la aguja | 2. | El empaque está desgastado o seco |

| | | | | | | |

| | El aire se fuga a través de | 1. | El vástago de la válvula se atasca | 1. | Lubríquelo |

| | la boquilla de aire aún sin | 2. | La válvula de aire o el asiento están con- | 2. | Límpielos |

| | apretar el gatillo | 3. | taminados | 3. | Reemplácela |

| | | | | | | La válvula de aire o el asiento están des- |

| | | | | | | | gastados o dañados | 4. | Reemplácela |

| | | | | | | 4. | El resorte de la válvula de aire está roto |

| | | | | | | 5. | El vástago de la válvula está torcido | 5. | Reemplácela |

| | | | | | |

| | El fluído se fuga a través de | 1. | La tuerca que sostiene el empaque está | 1. | Ajústela |

| | la boquilla de la pistola pul- | | muy apretada | | | |

| | 2. | La boquilla está desgastada o dañada | 2. | Reemplace la boquilla y aguja con un juego de boquilla/aguja |

| | verizadora a presión |

| | | | | | | 3. | La boquilla está sucia | | ondeados |

| | | | | | | 3. | Límpiela |

| | | | | | | 4. | El resorte de la aguja está roto | 4. | Reemplácela |

| | | | | | |

| | Rocío excesivo | 1. | La presión de atomización es muy alta | 1. | Reduzca la presión |

| | | | | | | 2. | La pistola está muy lejos de la superfi- | 2. | Acérquela a la superficie |

| | | | | | | | cie | | | |

3.Está pintando incorrectamente (está 3. El movimiento debe ser moderado y paralelo a la superficie moviendo la pistola muy rápido)

No puede rociar | 1. | La pistola no tiene presión | 1. | Revise las líneas de aire |

| 2. | El control de fluído está muy cerrado | 2. | Abra el control de fluído |

| 3. | El fluído está muy espeso | 3. | Diluya el fluído o use el sistema a presión |

| | | | |

23 Sp