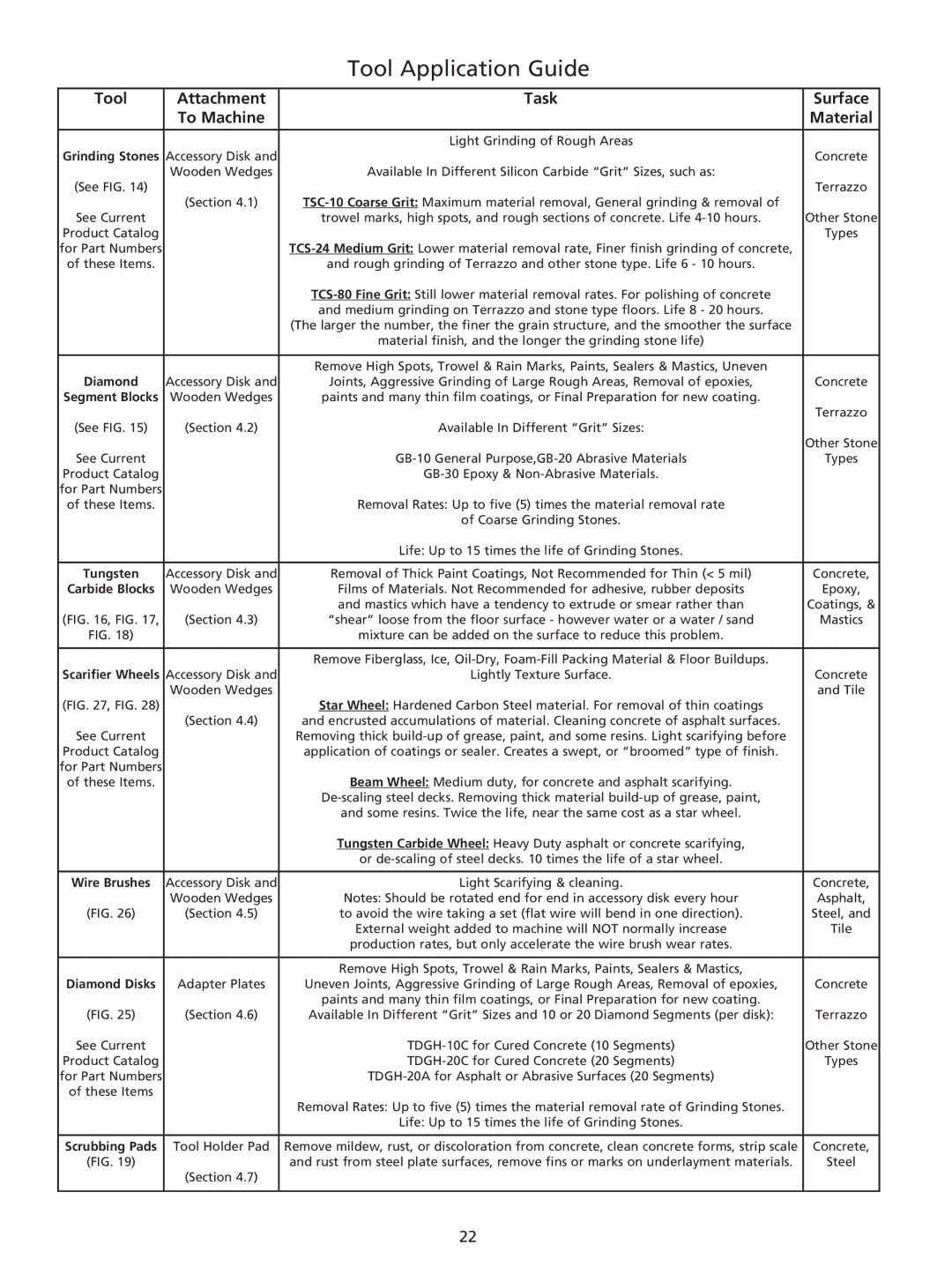

Tool Application Guide

Tool | Attachment | Task | Surface |

| To Machine |

| Material |

|

| Light Grinding of Rough Areas |

|

Grinding Stones | Accessory Disk and |

| Concrete |

| Wooden Wedges | Available In Different Silicon Carbide “Grit” Sizes, such as: |

|

(See FIG. 14) |

|

| Terrazzo |

| (Section 4.1) |

| |

See Current |

| trowel marks, high spots, and rough sections of concrete. Life | Other Stone |

Product Catalog |

|

| Types |

for Part Numbers |

|

| |

of these Items. |

| and rough grinding of Terrazzo and other stone type. Life 6 - 10 hours. |

|

|

|

| |

|

| and medium grinding on Terrazzo and stone type floors. Life 8 - 20 hours. |

|

|

| (The larger the number, the finer the grain structure, and the smoother the surface |

|

|

| material finish, and the longer the grinding stone life) |

|

|

|

|

|

|

| Remove High Spots, Trowel & Rain Marks, Paints, Sealers & Mastics, Uneven |

|

Diamond | Accessory Disk and | Joints, Aggressive Grinding of Large Rough Areas, Removal of epoxies, | Concrete |

Segment Blocks | Wooden Wedges | paints and many thin film coatings, or Final Preparation for new coating. |

|

|

|

| Terrazzo |

(See FIG. 15) | (Section 4.2) | Available In Different “Grit” Sizes: |

|

|

|

| Other Stone |

See Current |

| Types | |

Product Catalog |

|

| |

for Part Numbers |

|

|

|

of these Items. |

| Removal Rates: Up to five (5) times the material removal rate |

|

|

| of Coarse Grinding Stones. |

|

|

| Life: Up to 15 times the life of Grinding Stones. |

|

|

|

|

|

Tungsten | Accessory Disk and | Removal of Thick Paint Coatings, Not Recommended for Thin (< 5 mil) | Concrete, |

Carbide Blocks | Wooden Wedges | Films of Materials. Not Recommended for adhesive, rubber deposits | Epoxy, |

|

| and mastics which have a tendency to extrude or smear rather than | Coatings, & |

(FIG. 16, FIG. 17, | (Section 4.3) | “shear” loose from the floor surface - however water or a water / sand | Mastics |

FIG. 18) |

| mixture can be added on the surface to reduce this problem. |

|

|

|

|

|

|

| Remove Fiberglass, Ice, |

|

Scarifier Wheels | Accessory Disk and | Lightly Texture Surface. | Concrete |

| Wooden Wedges |

| and Tile |

(FIG. 27, FIG. 28) |

| Star Wheel: Hardened Carbon Steel material. For removal of thin coatings |

|

| (Section 4.4) | and encrusted accumulations of material. Cleaning concrete of asphalt surfaces. |

|

See Current |

| Removing thick |

|

Product Catalog |

| application of coatings or sealer. Creates a swept, or “broomed” type of finish. |

|

for Part Numbers |

|

|

|

of these Items. |

| Beam Wheel: Medium duty, for concrete and asphalt scarifying. |

|

|

|

| |

|

| and some resins. Twice the life, near the same cost as a star wheel. |

|

|

| Tungsten Carbide Wheel: Heavy Duty asphalt or concrete scarifying, |

|

|

| or |

|

|

|

|

|

Wire Brushes | Accessory Disk and | Light Scarifying & cleaning. | Concrete, |

| Wooden Wedges | Notes: Should be rotated end for end in accessory disk every hour | Asphalt, |

(FIG. 26) | (Section 4.5) | to avoid the wire taking a set (flat wire will bend in one direction). | Steel, and |

|

| External weight added to machine will NOT normally increase | Tile |

|

| production rates, but only accelerate the wire brush wear rates. |

|

|

|

|

|

|

| Remove High Spots, Trowel & Rain Marks, Paints, Sealers & Mastics, |

|

Diamond Disks | Adapter Plates | Uneven Joints, Aggressive Grinding of Large Rough Areas, Removal of epoxies, | Concrete |

|

| paints and many thin film coatings, or Final Preparation for new coating. |

|

(FIG. 25) | (Section 4.6) | Available In Different “Grit” Sizes and 10 or 20 Diamond Segments (per disk): | Terrazzo |

See Current |

| Other Stone | |

Product Catalog |

| Types | |

for Part Numbers |

|

| |

of these Items |

|

|

|

|

| Removal Rates: Up to five (5) times the material removal rate of Grinding Stones. |

|

|

| Life: Up to 15 times the life of Grinding Stones. |

|

|

|

|

|

Scrubbing Pads | Tool Holder Pad | Remove mildew, rust, or discoloration from concrete, clean concrete forms, strip scale | Concrete, |

(FIG. 19) |

| and rust from steel plate surfaces, remove fins or marks on underlayment materials. | Steel |

| (Section 4.7) |

|

|

|

|

|

|

22