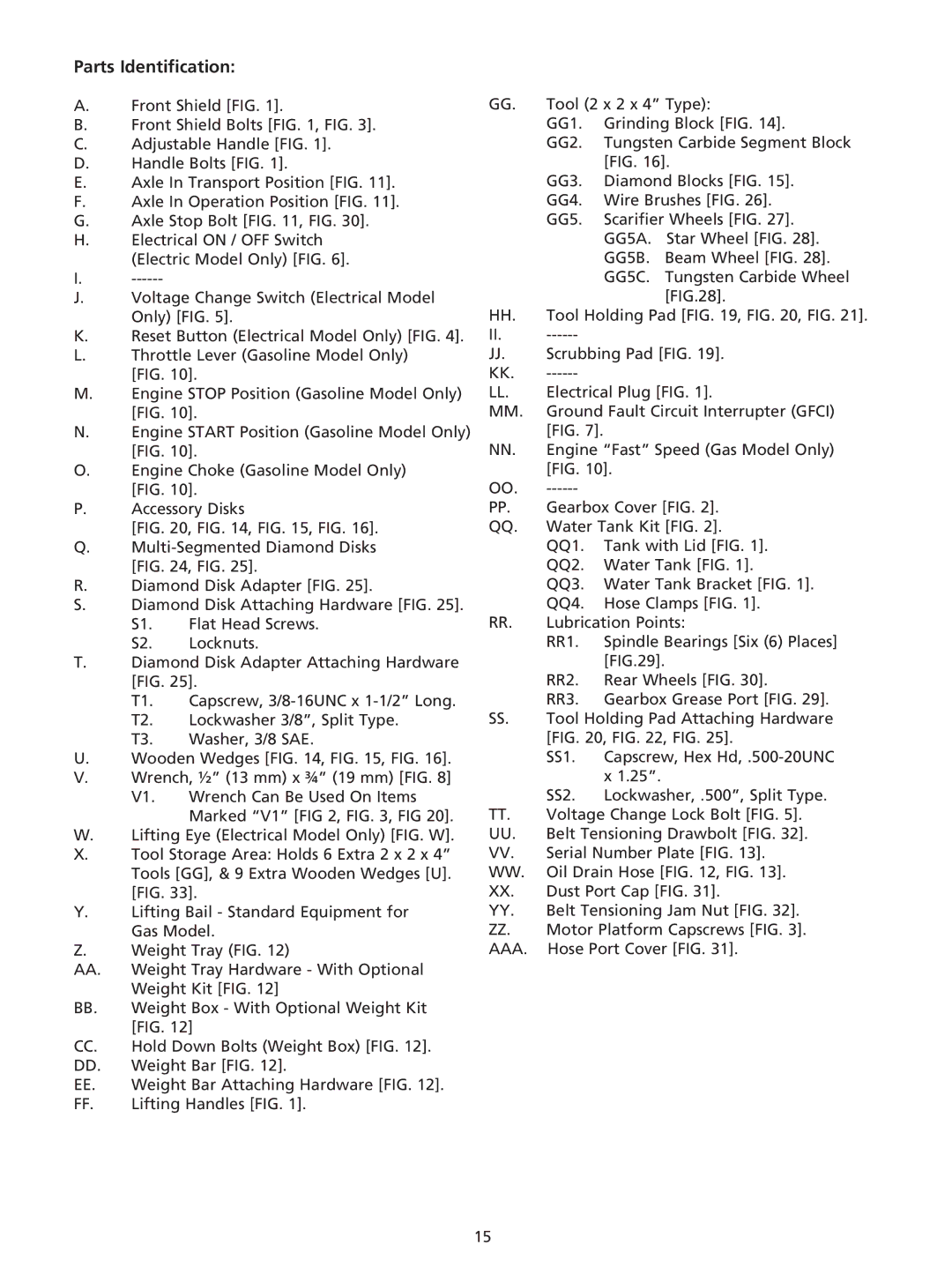

Parts Identification:

A.Front Shield [FIG. 1].

B.Front Shield Bolts [FIG. 1, FIG. 3].

C.Adjustable Handle [FIG. 1].

D.Handle Bolts [FIG. 1].

E.Axle In Transport Position [FIG. 11].

F.Axle In Operation Position [FIG. 11].

G.Axle Stop Bolt [FIG. 11, FIG. 30].

H.Electrical ON / OFF Switch (Electric Model Only) [FIG. 6].

I.

J.Voltage Change Switch (Electrical Model Only) [FIG. 5].

K.Reset Button (Electrical Model Only) [FIG. 4].

L.Throttle Lever (Gasoline Model Only) [FIG. 10].

M.Engine STOP Position (Gasoline Model Only) [FIG. 10].

N.Engine START Position (Gasoline Model Only) [FIG. 10].

O.Engine Choke (Gasoline Model Only) [FIG. 10].

P.Accessory Disks

[FIG. 20, FIG. 14, FIG. 15, FIG. 16].

Q.

R.Diamond Disk Adapter [FIG. 25].

S.Diamond Disk Attaching Hardware [FIG. 25].

S1. Flat Head Screws.

S2. Locknuts.

T.Diamond Disk Adapter Attaching Hardware [FIG. 25].

T1. Capscrew,

T2. Lockwasher 3/8”, Split Type.

T3. Washer, 3/8 SAE.

U.Wooden Wedges [FIG. 14, FIG. 15, FIG. 16].

V.Wrench, ½” (13 mm) x ¾” (19 mm) [FIG. 8] V1. Wrench Can Be Used On Items

Marked “V1” [FIG 2, FIG. 3, FIG 20].

W.Lifting Eye (Electrical Model Only) [FIG. W].

X.Tool Storage Area: Holds 6 Extra 2 x 2 x 4” Tools [GG], & 9 Extra Wooden Wedges [U]. [FIG. 33].

Y.Lifting Bail - Standard Equipment for Gas Model.

Z.Weight Tray (FIG. 12)

AA.Weight Tray Hardware - With Optional Weight Kit [FIG. 12]

BB.Weight Box - With Optional Weight Kit [FIG. 12]

CC.Hold Down Bolts (Weight Box) [FIG. 12].

DD.Weight Bar [FIG. 12].

EE.Weight Bar Attaching Hardware [FIG. 12].

FF.Lifting Handles [FIG. 1].

GG.Tool (2 x 2 x 4” Type):

GG1. Grinding Block [FIG. 14].

GG2. Tungsten Carbide Segment Block [FIG. 16].

GG3. Diamond Blocks [FIG. 15]. GG4. Wire Brushes [FIG. 26]. GG5. Scarifier Wheels [FIG. 27].

GG5A. Star Wheel [FIG. 28]. GG5B. Beam Wheel [FIG. 28]. GG5C. Tungsten Carbide Wheel

[FIG.28].

HH.Tool Holding Pad [FIG. 19, FIG. 20, FIG. 21].

II.

JJ.Scrubbing Pad [FIG. 19].

KK.

LL.Electrical Plug [FIG. 1].

MM.Ground Fault Circuit Interrupter (GFCI) [FIG. 7].

NN.Engine “Fast” Speed (Gas Model Only) [FIG. 10].

OO.

PP.Gearbox Cover [FIG. 2].

QQ.Water Tank Kit [FIG. 2]. QQ1. Tank with Lid [FIG. 1]. QQ2. Water Tank [FIG. 1].

QQ3. Water Tank Bracket [FIG. 1]. QQ4. Hose Clamps [FIG. 1].

RR.Lubrication Points:

RR1. Spindle Bearings [Six (6) Places] [FIG.29].

RR2. Rear Wheels [FIG. 30].

RR3. Gearbox Grease Port [FIG. 29].

SS.Tool Holding Pad Attaching Hardware [FIG. 20, FIG. 22, FIG. 25].

SS1. Capscrew, Hex

x1.25”.

SS2. Lockwasher, .500”, Split Type.

TT.Voltage Change Lock Bolt [FIG. 5].

UU.Belt Tensioning Drawbolt [FIG. 32].

VV.Serial Number Plate [FIG. 13].

WW.Oil Drain Hose [FIG. 12, FIG. 13].

XX.Dust Port Cap [FIG. 31].

YY.Belt Tensioning Jam Nut [FIG. 32].

ZZ.Motor Platform Capscrews [FIG. 3].

AAA.Hose Port Cover [FIG. 31].

15