All machine adjustments & maintenance shall only be done after the machine’s power switch has been put in the “OFF” position & the power supply cord completely disconnected.

•Make sure that the extension cord length is properly sized for the motor used on this saw. See the chart in Section 2 of this document.

•Single phase

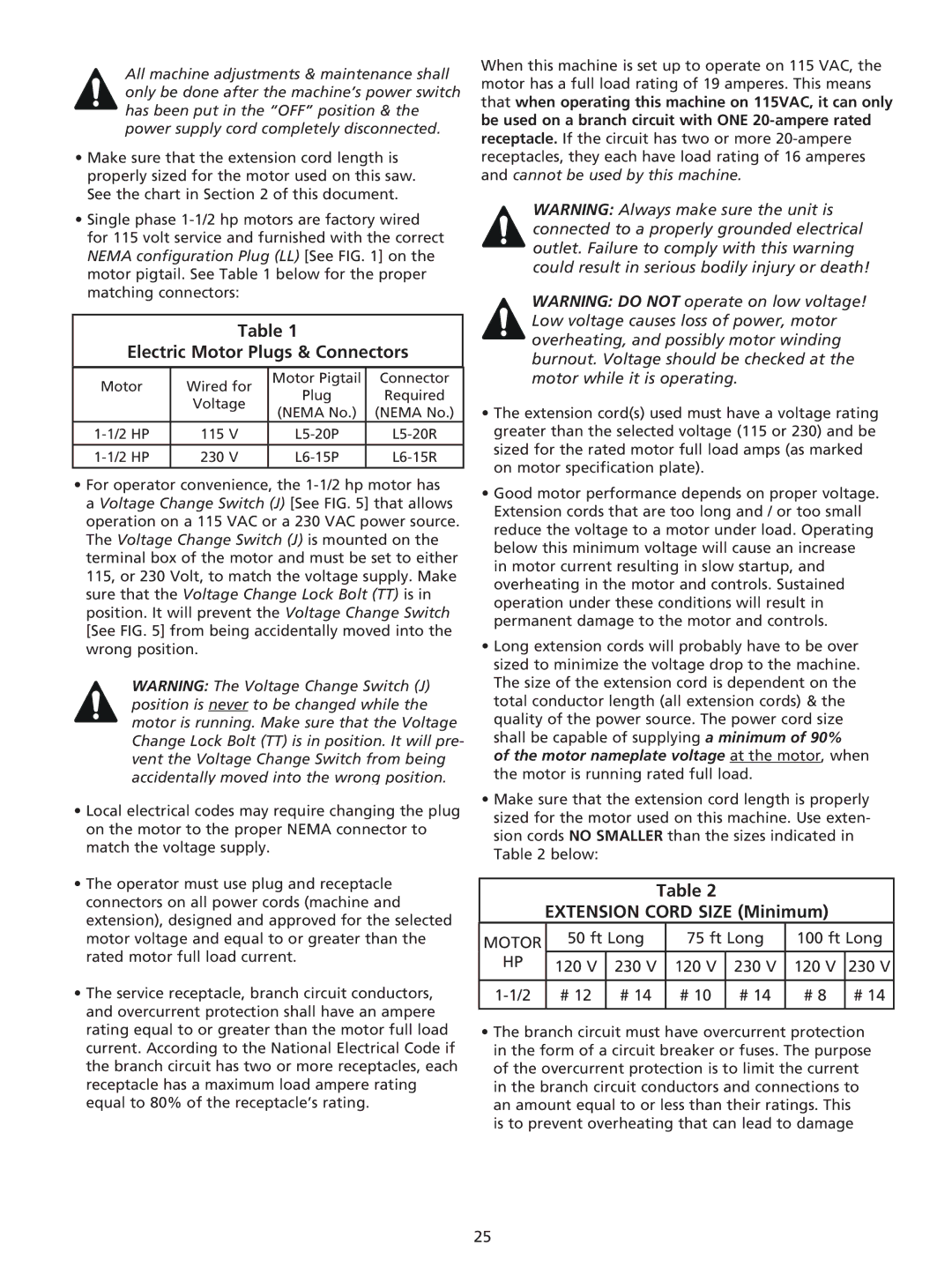

Table 1

Electric Motor Plugs & Connectors

Motor | Wired for | Motor Pigtail | Connector | |

Plug | Required | |||

| Voltage | |||

| (NEMA No.) | (NEMA No.) | ||

|

| |||

115 V | ||||

230 V |

•For operator convenience, the

WARNING: The Voltage Change Switch (J) position is never to be changed while the motor is running. Make sure that the Voltage Change Lock Bolt (TT) is in position. It will pre- vent the Voltage Change Switch from being accidentally moved into the wrong position.

•Local electrical codes may require changing the plug on the motor to the proper NEMA connector to match the voltage supply.

•The operator must use plug and receptacle connectors on all power cords (machine and extension), designed and approved for the selected motor voltage and equal to or greater than the rated motor full load current.

•The service receptacle, branch circuit conductors, and overcurrent protection shall have an ampere rating equal to or greater than the motor full load current. According to the National Electrical Code if the branch circuit has two or more receptacles, each receptacle has a maximum load ampere rating equal to 80% of the receptacle’s rating.

When this machine is set up to operate on 115 VAC, the motor has a full load rating of 19 amperes. This means that when operating this machine on 115VAC, it can only be used on a branch circuit with ONE

WARNING: Always make sure the unit is connected to a properly grounded electrical outlet. Failure to comply with this warning could result in serious bodily injury or death!

WARNING: DO NOT operate on low voltage! Low voltage causes loss of power, motor overheating, and possibly motor winding burnout. Voltage should be checked at the motor while it is operating.

•The extension cord(s) used must have a voltage rating greater than the selected voltage (115 or 230) and be sized for the rated motor full load amps (as marked on motor specification plate).

•Good motor performance depends on proper voltage. Extension cords that are too long and / or too small reduce the voltage to a motor under load. Operating below this minimum voltage will cause an increase in motor current resulting in slow startup, and overheating in the motor and controls. Sustained operation under these conditions will result in permanent damage to the motor and controls.

•Long extension cords will probably have to be over sized to minimize the voltage drop to the machine. The size of the extension cord is dependent on the total conductor length (all extension cords) & the quality of the power source. The power cord size shall be capable of supplying a minimum of 90% of the motor nameplate voltage at the motor, when the motor is running rated full load.

•Make sure that the extension cord length is properly sized for the motor used on this machine. Use exten- sion cords NO SMALLER than the sizes indicated in Table 2 below:

Table 2

EXTENSION CORD SIZE (Minimum)

MOTOR | 50 ft Long | 75 ft Long | 100 ft Long | |||

HP | 120 V | 230 V | 120 V | 230 V | 120 V | 230 V |

|

|

|

|

|

|

|

# 12 | # 14 | # 10 | # 14 | # 8 | # 14 | |

|

|

|

|

|

|

|

•The branch circuit must have overcurrent protection in the form of a circuit breaker or fuses. The purpose of the overcurrent protection is to limit the current in the branch circuit conductors and connections to an amount equal to or less than their ratings. This is to prevent overheating that can lead to damage

25