MAINTENANCE

Lubricating the bar tip sprocket

Lubricate the bar tip sprocket each time you refuel. Use the special grease gun and a good quality bearing grease.

Needle bearing lubrication

The clutch drum has a needle bearing on the output shaft. This needle bearing must be lubricated regularly (once a week).

When lubricating, remove the clutch cover by loosening the bar nut. Lay the saw on its side with the clutch drum upwards.

Lubrication involves grease being squirted into the centre of the crankshaft using a grease gun.

Adjustment of the oil pump

The oil pump is adjustable. Adjustments are made by turning the screw with a screwdriver. Turning the screw

clockwise will increase the oil flow, turning it anticlockwise will reduce the oil flow.

The oil tank should become nearly empty by time fuel is used up. Be sure to refill the oil tank every time when refueling the saw.

! | WARNING! The engine must be stopped | |

when making adjustments. | ||

|

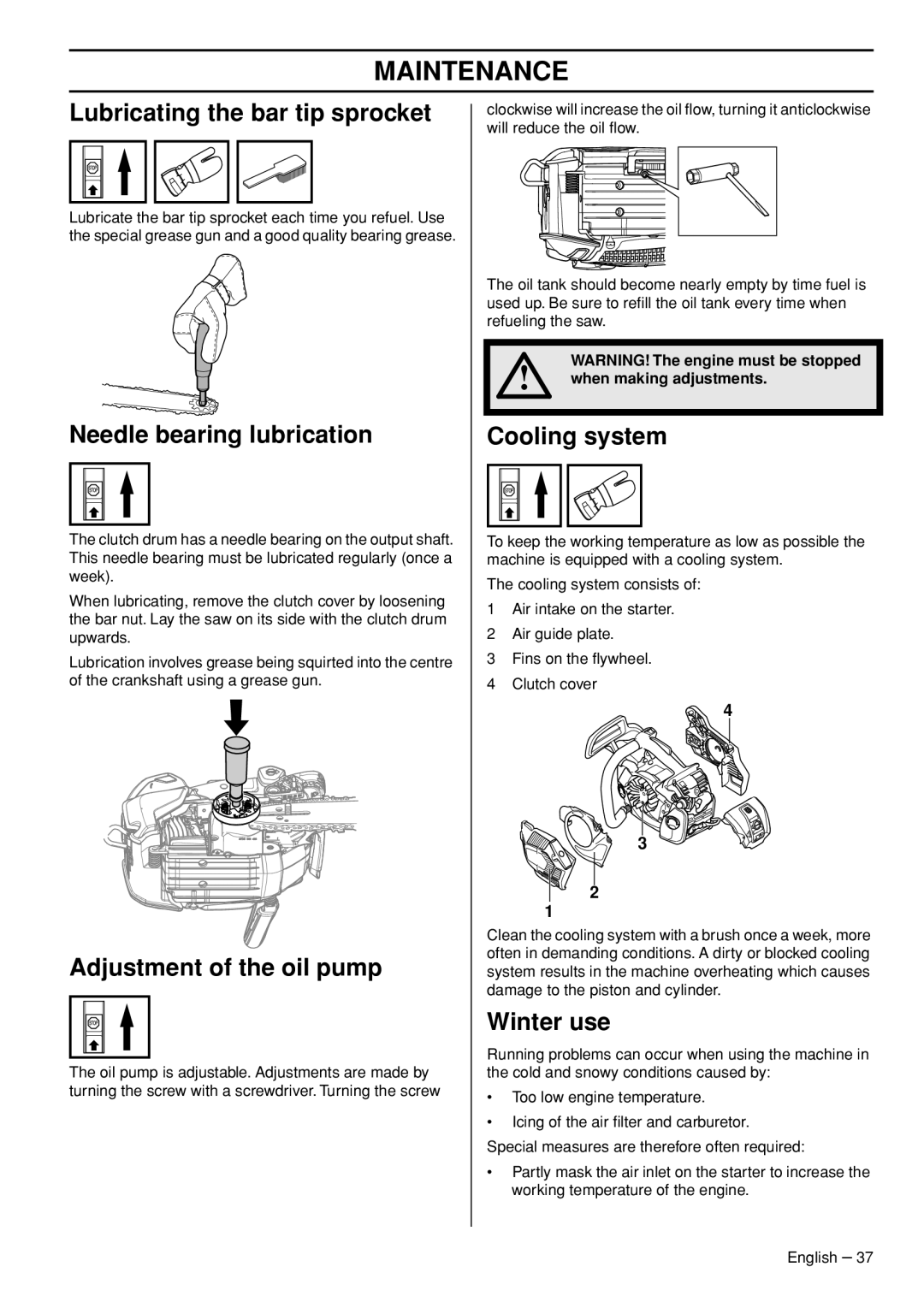

Cooling system

To keep the working temperature as low as possible the machine is equipped with a cooling system.

The cooling system consists of:

1Air intake on the starter.

2Air guide plate.

3Fins on the flywheel.

4Clutch cover

4

3

2

1

Clean the cooling system with a brush once a week, more often in demanding conditions. A dirty or blocked cooling system results in the machine overheating which causes damage to the piston and cylinder.

Winter use

Running problems can occur when using the machine in the cold and snowy conditions caused by:

•Too low engine temperature.

•Icing of the air filter and carburetor. Special measures are therefore often required:

•Partly mask the air inlet on the starter to increase the working temperature of the engine.

English – 37