20

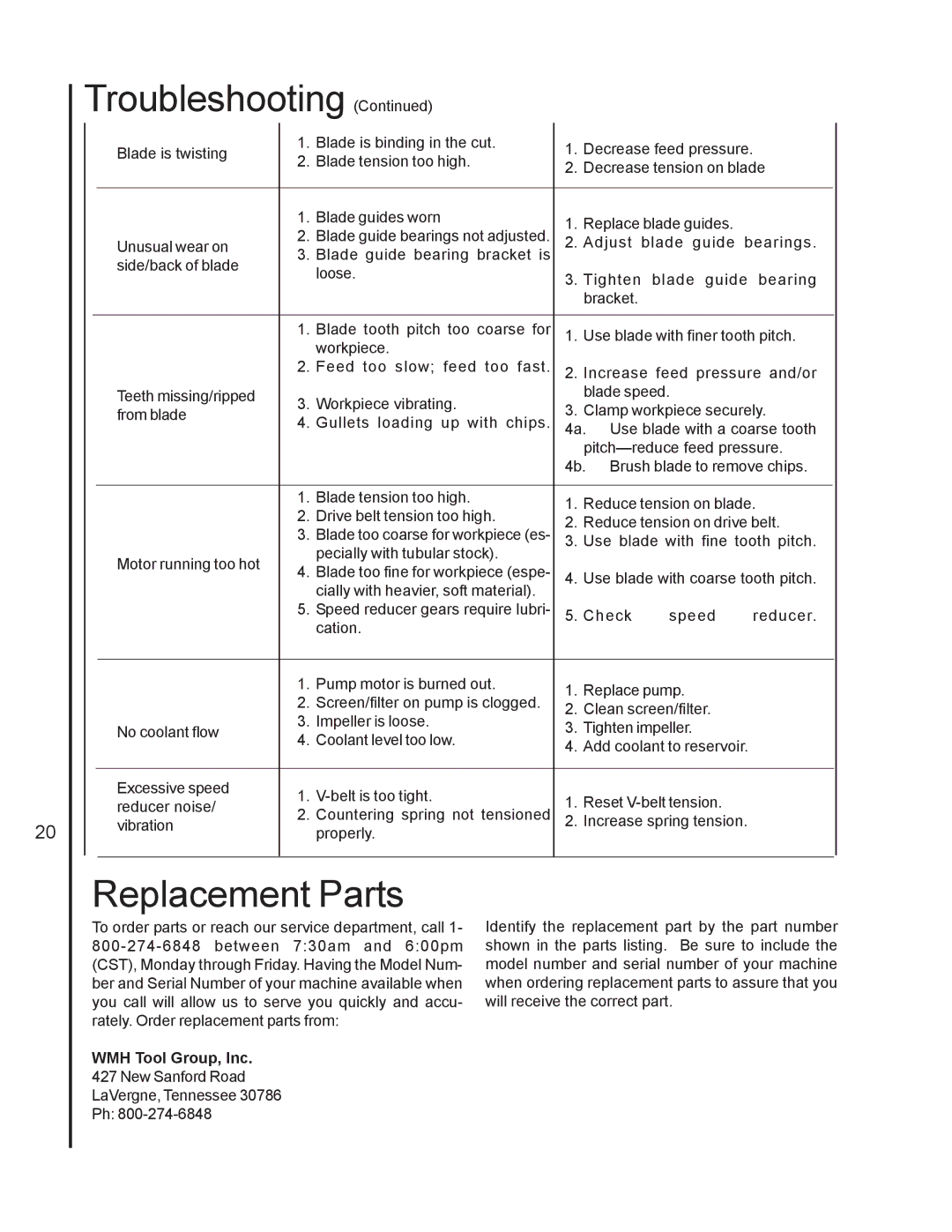

Troubleshooting (Continued)

|

| Blade is twisting | 1. | Blade is binding in the cut. | 1. | Decrease feed pressure. | ||

|

| 2. | Blade tension too high. | |||||

|

|

| 2. | Decrease tension on blade | ||||

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

| 1. | Blade guides worn | 1. | Replace blade guides. |

| |

|

|

| 2. Blade guide bearings not adjusted. |

| ||||

|

| Unusual wear on | 2. | Adjust | blade guide bearings. | |||

|

| side/back of blade | 3. | Blade guide bearing bracket is |

|

|

|

|

|

|

| loose. | 3. | Tighten | blade guide | bearing | |

|

|

|

| |||||

|

|

|

|

| ||||

|

|

|

|

|

| bracket. |

|

|

|

|

|

|

|

|

| ||

|

|

| 1. | Blade tooth pitch too coarse for | 1. | Use blade with finer tooth pitch. | ||

|

|

|

| workpiece. |

|

|

|

|

|

|

| 2. | Feed too slow; feed too fast. | 2. | Increase feed pressure and/or | ||

|

| Teeth missing/ripped | 3. | Workpiece vibrating. |

| blade speed. |

| |

|

| from blade | 3. | Clamp workpiece securely. | ||||

|

| 4. | Gullets loading up with chips. | |||||

|

|

| 4a. Use blade with a coarse tooth | |||||

|

|

|

|

|

| |||

|

|

|

|

| 4b. Brush blade to remove chips. | |||

|

|

|

|

|

|

|

|

|

|

|

| 1. | Blade tension too high. | 1. | Reduce tension on blade. | ||

|

|

| 2. | Drive belt tension too high. | ||||

|

|

| 2. | Reduce tension on drive belt. | ||||

|

|

| 3. | Blade too coarse for workpiece (es- | ||||

|

|

| 3. | Use blade with fine tooth pitch. | ||||

|

| Motor running too hot |

| pecially with tubular stock). |

|

|

|

|

|

| 4. | Blade too fine for workpiece (espe- | 4. | Use blade with coarse tooth pitch. | |||

|

|

| ||||||

|

|

|

| cially with heavier, soft material). |

|

|

|

|

|

|

| 5. | Speed reducer gears require lubri- | 5. | Check | speed | reducer. |

|

|

|

| cation. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1. | Pump motor is burned out. | 1. | Replace pump. |

| |

|

|

| 2. | Screen/filter on pump is clogged. |

| |||

|

|

| 2. | Clean screen/filter. |

| |||

|

|

| 3. | Impeller is loose. |

| |||

|

| No coolant flow | 3. | Tighten impeller. |

| |||

|

| 4. | Coolant level too low. |

| ||||

|

|

| 4. | Add coolant to reservoir. |

| |||

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

| Excessive speed | 1. | 1. | Reset |

| ||

|

| reducer noise/ |

| |||||

|

| 2. Countering spring not tensioned |

| |||||

|

| vibration | 2. | Increase spring tension. |

| |||

|

|

|

| properly. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Replacement Parts

To order parts or reach our service department, call 1-

WMH Tool Group, Inc.

427 New Sanford Road

LaVergne, Tennessee 30786

Ph:

Identify the replacement part by the part number shown in the parts listing. Be sure to include the model number and serial number of your machine when ordering replacement parts to assure that you will receive the correct part.