8

Raising/Lowering the Saw Head

1.Lift the saw head using the handle on the far left side of the saw head.

2.To lower the saw head, press the green pushbutton on the right side of the control panel.

3.To adjust the feed rate, adjust the feed rate control valve knob on the top of the saw head (see figure 3).

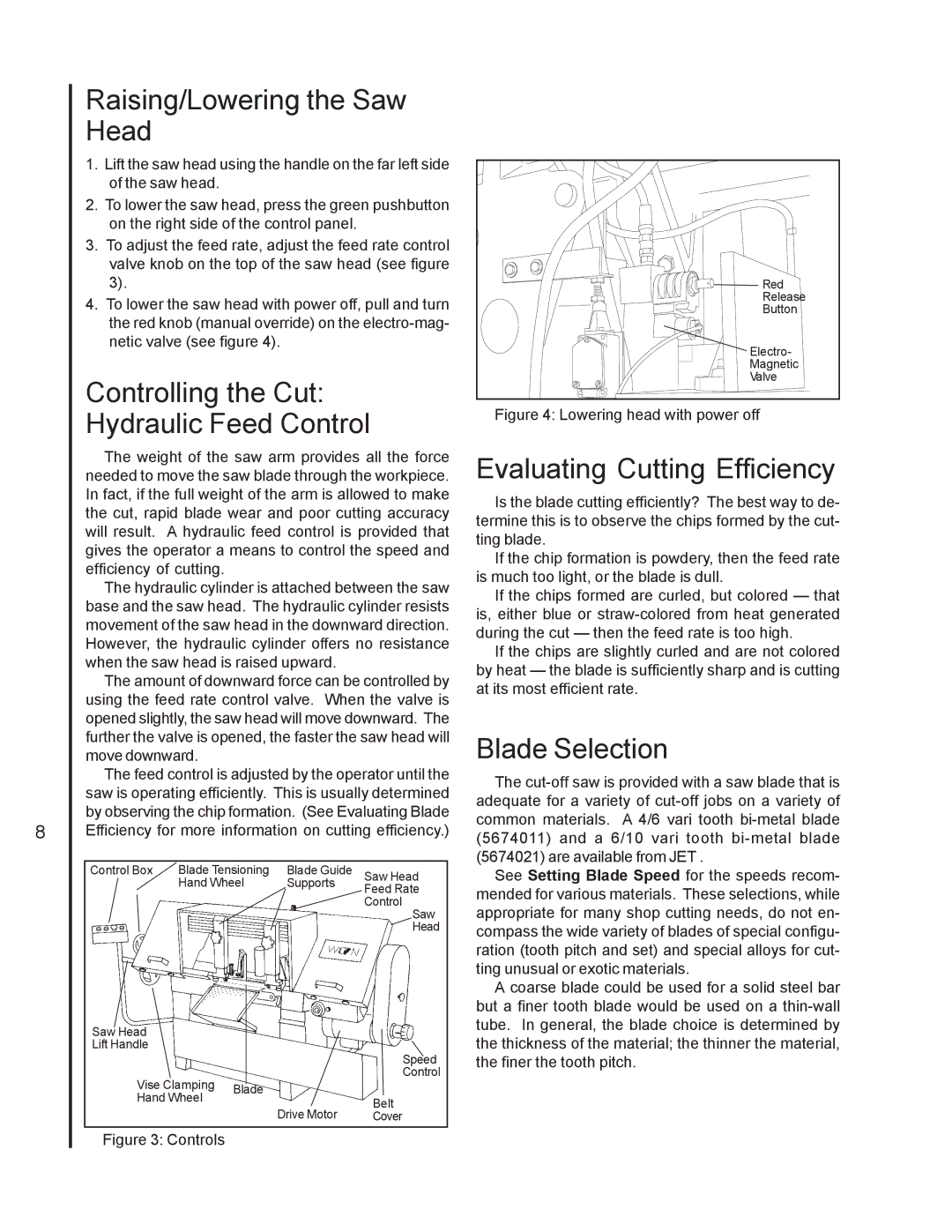

4.To lower the saw head with power off, pull and turn the red knob (manual override) on the

Controlling the Cut: Hydraulic Feed Control

The weight of the saw arm provides all the force needed to move the saw blade through the workpiece. In fact, if the full weight of the arm is allowed to make the cut, rapid blade wear and poor cutting accuracy will result. A hydraulic feed control is provided that gives the operator a means to control the speed and efficiency of cutting.

The hydraulic cylinder is attached between the saw base and the saw head. The hydraulic cylinder resists movement of the saw head in the downward direction. However, the hydraulic cylinder offers no resistance when the saw head is raised upward.

The amount of downward force can be controlled by using the feed rate control valve. When the valve is opened slightly, the saw head will move downward. The further the valve is opened, the faster the saw head will move downward.

The feed control is adjusted by the operator until the saw is operating efficiently. This is usually determined by observing the chip formation. (See Evaluating Blade Efficiency for more information on cutting efficiency.)

Control Box Blade Tensioning Blade Guide Saw Head

Hand Wheel Supports Feed Rate

Control

Saw

Head

Saw Head

Lift Handle

|

| Speed | |

Vise Clamping |

| Control | |

Blade |

| ||

Hand Wheel | Belt | ||

| |||

| Drive Motor | ||

| Cover |

Figure 3: Controls

Red |

Release |

Button |

Electro- |

Magnetic |

Valve |

Figure 4: Lowering head with power off

Evaluating Cutting Efficiency

Is the blade cutting efficiently? The best way to de- termine this is to observe the chips formed by the cut- ting blade.

If the chip formation is powdery, then the feed rate is much too light, or the blade is dull.

If the chips formed are curled, but colored — that is, either blue or

If the chips are slightly curled and are not colored by heat — the blade is sufficiently sharp and is cutting at its most efficient rate.

Blade Selection

The

See Setting Blade Speed for the speeds recom- mended for various materials. These selections, while appropriate for many shop cutting needs, do not en- compass the wide variety of blades of special configu- ration (tooth pitch and set) and special alloys for cut- ting unusual or exotic materials.

A coarse blade could be used for a solid steel bar but a finer tooth blade would be used on a