Woodstove F 400 specifications

The Jotul F 400 is a leading model in the Jotul line of woodstoves, renowned for its combination of efficiency, aesthetics, and robust craftsmanship. As one of the company's most popular models, it seamlessly blends functionality with timeless design, making it an ideal choice for both contemporary and traditional spaces.One of the primary features of the Jotul F 400 is its impressive heating capacity. With an ability to heat spaces of up to 2,000 square feet, this woodstove is perfect for larger rooms or open floor plans. Its firebox can accommodate logs up to 20 inches in length, allowing for longer burn times and fewer refuels. With an average efficiency rating of around 78%, the F 400 ensures that most of the wood's energy is converted into usable heat rather than lost up the chimney.

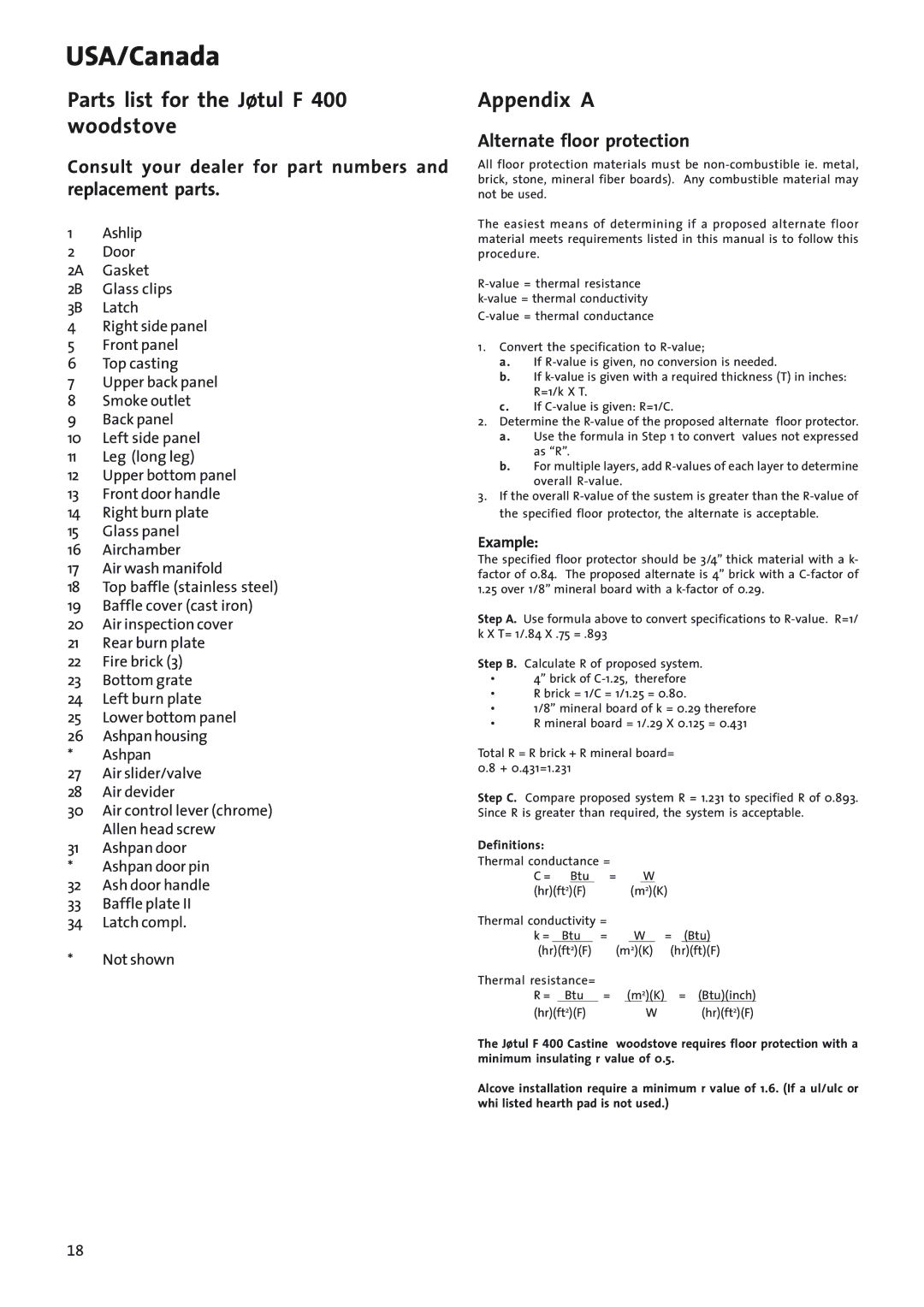

In terms of design, the Jotul F 400 showcases the classic Norwegian aesthetic that Jotul is known for. Its cast iron construction not only contributes to its durability but also aids in heat retention, ensuring that the stove continues to radiate warmth long after the fire has diminished. The intricate detailing and optional enamel finishes give it an elegant touch, making it a statement piece in any home.

The Jotul F 400 is equipped with advanced combustion technology that promotes a cleaner burn, resulting in reduced emissions. This feature is particularly important in today’s environmentally conscious market, as it aligns with stricter regulations on woodstove emissions. The stove features a secondary combustion system that helps to maximize fuel efficiency while minimizing smoke output, allowing users to enjoy the ambiance of a wood fire without excessive pollutants.

Another notable characteristic of the F 400 is its easy-to-use air control system. This allows users to easily adjust the airflow to the fire, optimizing it for lighting, burning, and maintaining desired temperatures. The large, self-cleaning glass door provides an unobstructed view of the flames, enhancing the ambiance of any room.

In summary, the Jotul F 400 woodstove is a blend of efficiency, beauty, and innovation. Its capacity to heat large spaces, coupled with advanced combustion technology and classic design, makes it one of the top choices for homeowners looking for a reliable and attractive heating solution. Whether for cozy evenings or efficient heating, the Jotul F 400 is sure to enhance any living space.