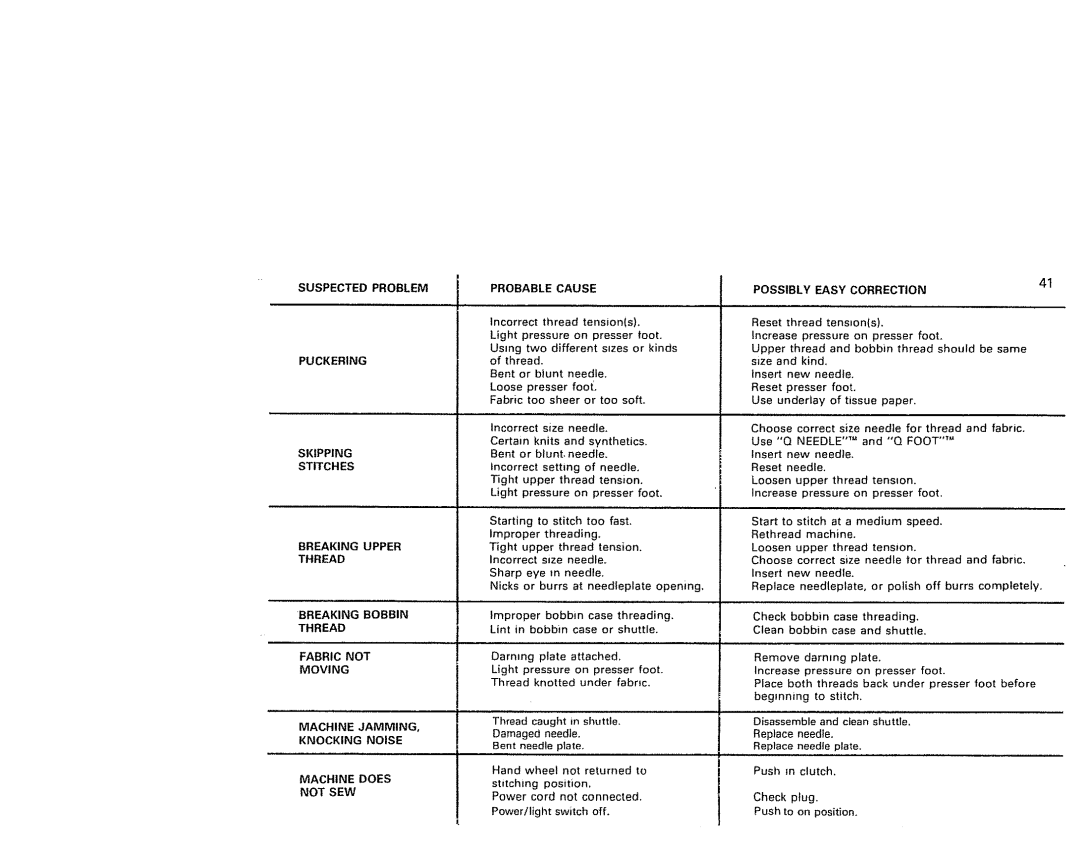

SUSPECTED PROBLEM

PUCKERING

SKIPPING

STITCHES

BREAKING UPPER THREAD

BREAKING BOBBIN

THREAD

FABRIC NOT

MOVING

MACHINE JAMMING,

KNOCKING NOISE

MACHINE DOES

NOT SEW

PROBABLE CAUSE

Incorrect thread tension{s),

Light pressure on presser foot. Using two different sizes or kinds of thread.

Sent or blunt needle. Loose presser foot_.

Fabric too sheer or too soft.

Incorrect size needle.

Certain knits and synthetics.

Bent or blunt, needle.

incorrect setting of needle, Tight upper thread tension, Light pressure on presser foot.

Starting to stitch too fast.

Improper threading.

Tight upper thread tension.

Incorrect size needle.

Sharp eye m needle.

Nicks or burrs at needepiate opening,

Improper bobbin case threading.

!Lint in bobbin case or shuttle.

J Darning plate attached.

t Light pressure on presser foot. Thread knotted under fabric,

i

Thread caught in shuttle.

Damaged needle.

Bent needle plate.

Hand wheel not returned to

stitching position,

Power cord not connected, Power!light switch off.

POSSIBLY EASY CORRECTION | 41 |

|

Reset thread tension(s),

Increase pressure on presser foot.

Upper thread and bobbin thread should be same size and kind.

Insert new needle. Reset presser foot.

Use underlay of tissue paper.

Choose correct size needle for thread and fabric. Use "Q NEEDLE .... and "Q FOOT "T"

insert new needle. Reset needle.

Loosen upper thread tension.

Increase pressure on presser foot.

Start to stitch at a medium speed.

Rethread machine.

Loosen upper thread tension.

Choose correct size needle for thread and fabric, Insert new needle.

Replace needleplate, or polish off burrs completely.

Check bobbin case threading.

Clean bobbin case and shuttle.

Remove darning ptate.

Increase pressure on presser foot.

Place both threads back under presser foot before

beginning to stitch.

Disassemble and ctean shuttle,

Replace needle.

Replace needle plate,

Push m clutch,

Check plug.

Push to on position.