STEP lb. Cut 1 inch of insulation from the end of each insulated wire. Shape

the end of each wire into a "U" shaped hook.

STEP 2. Remove

STEP 4. Loosen or remove terminal block screws. Connect the neutral wire (white

or center) of direct wire cable under the center screw of the terminal block.

STEP 4a. Place the

of the wire over the terminal block screw.

The open side of the hook should face to the right. Squeeze hook end of wire together to form a loop.

| Terminalblockcover |

|

|

| ||

|

|

|

| |||

|

|

| STEP 5. Connect the other two wires | |||

|

|

| to outer terminal block screws using the | |||

|

|

| same method(s) described in STEP 4a. | |||

|

|

| Tighten all terminal block screws firmly. | |||

|

|

| STEP 6. "lqghten the strain relief screws. | |||

|

|

| STEP 7. Insert tab of terminal block | |||

|

|

| cover into slot of the dryer rear panel. | |||

|

|

| Secure cover with | |||

|

|

| If local codes do not permit the | |||

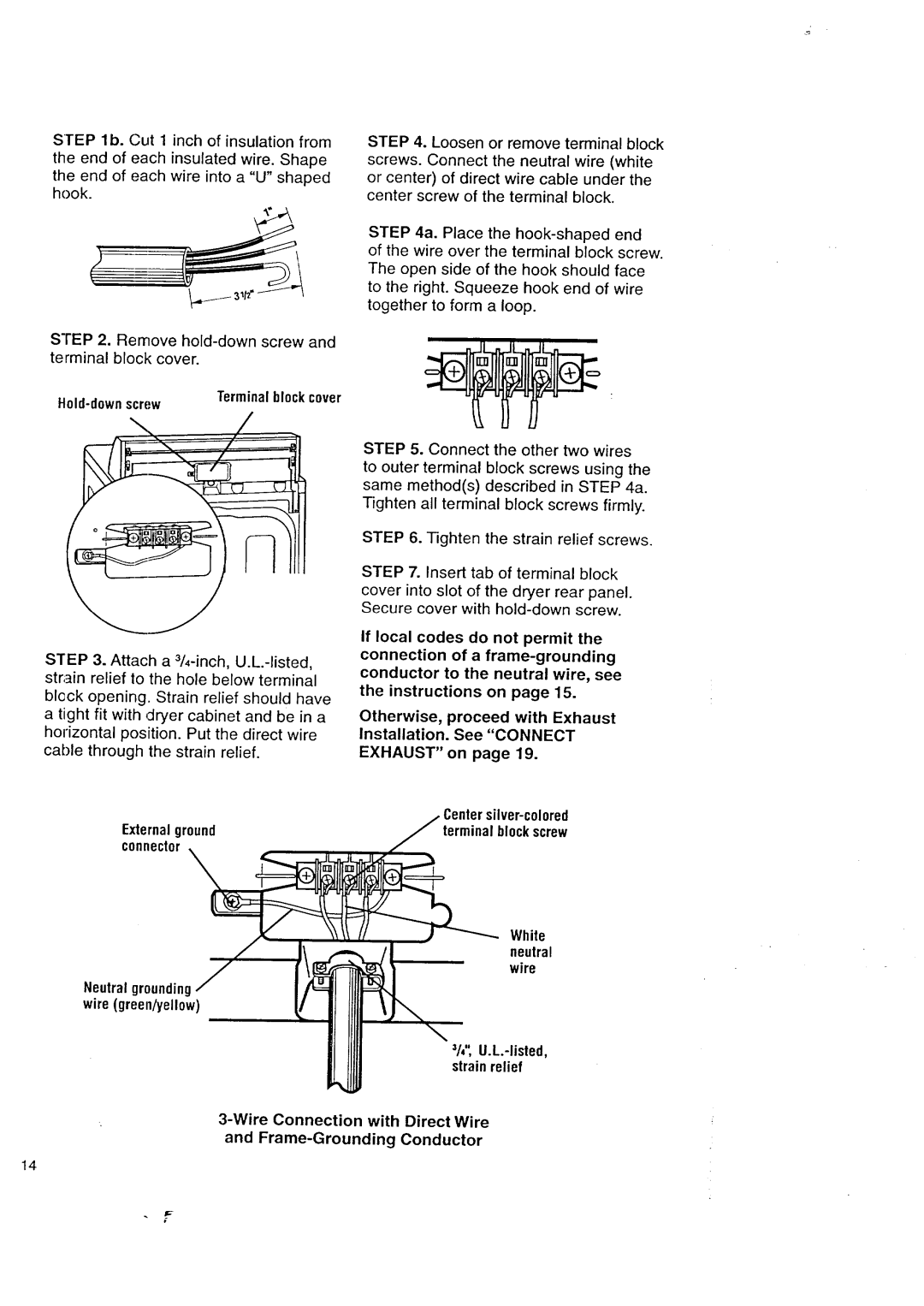

STEP 3. Attach a | connection of a | |||||

conductor to the neutral wire, see | ||||||

strain relief to the hole below terminal | ||||||

the instructions on page 15. | ||||||

block opening. Strain relief should have | ||||||

Otherwise, | proceed | with Exhaust | ||||

a tight fit with | dryer cabinet and be in a | |||||

horizontal position. Put the direct wire | Installation. | See "CONNECT | ||||

EXHAUST" | on page | 19. | ||||

cable through | the strain relief. | |||||

colored

Externalgroundterminal blockscrew

connector_

White neutral wire

Neutral grounding

wire (green/yell0w)

and

14