CARE AND OPERATION | FUEL |

REFUELING

To refuel the stove, open the bypass damper and move the primary air control to "HIGH." Let the fire "LIVEN UP" for about one minute. Open the fuel door about ½” (1 cm) and hold in this position about 30 seconds or until the stove is drafting well. Open the door and add wood. After refueling, reset the primary draft control to the desired po- sition, and close the bypass when the catalytic tempera- ture probe reaches operating temperatures of 600° F indi- cated on the temperature probe.

BYPASS DAMPER CONTROL

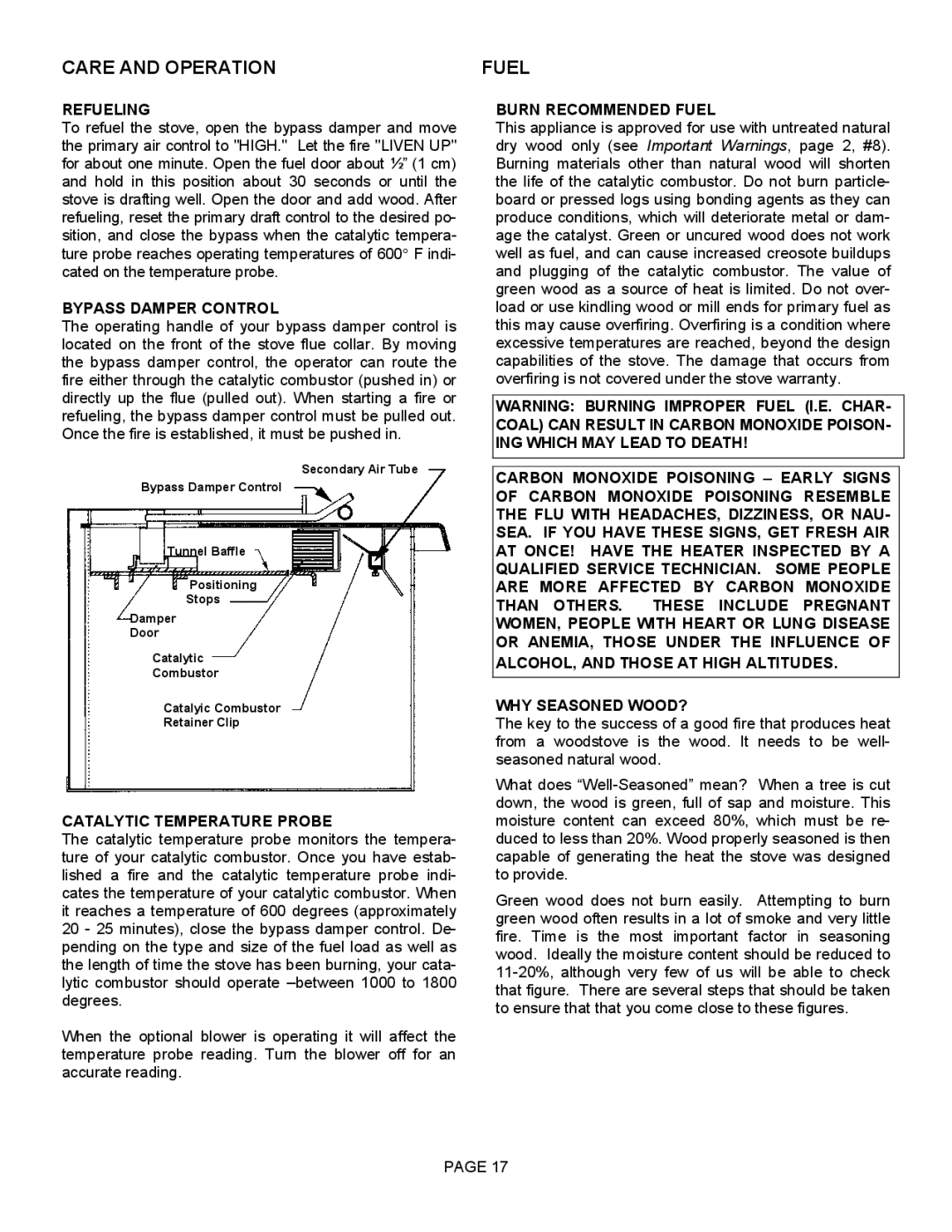

The operating handle of your bypass damper control is located on the front of the stove flue collar. By moving the bypass damper control, the operator can route the fire either through the catalytic combustor (pushed in) or directly up the flue (pulled out). When starting a fire or refueling, the bypass damper control must be pulled out. Once the fire is established, it must be pushed in.

Secondary Air Tube

Bypass Damper Control

Tunnel Baffle

Positioning

Stops

Damper

Door

Catalytic

Combustor

Catalyic Combustor

Retainer Clip

CATALYTIC TEMPERATURE PROBE

The catalytic temperature probe monitors the tempera- ture of your catalytic combustor. Once you have estab- lished a fire and the catalytic temperature probe indi- cates the temperature of your catalytic combustor. When it reaches a temperature of 600 degrees (approximately 20 - 25 minutes), close the bypass damper control. De- pending on the type and size of the fuel load as well as the length of time the stove has been burning, your cata- lytic combustor should operate

When the optional blower is operating it will affect the temperature probe reading. Turn the blower off for an accurate reading.

BURN RECOMMENDED FUEL

This appliance is approved for use with untreated natural dry wood only (see Important Warnings, page 2, #8). Burning materials other than natural wood will shorten the life of the catalytic combustor. Do not burn particle- board or pressed logs using bonding agents as they can produce conditions, which will deteriorate metal or dam- age the catalyst. Green or uncured wood does not work well as fuel, and can cause increased creosote buildups and plugging of the catalytic combustor. The value of green wood as a source of heat is limited. Do not over- load or use kindling wood or mill ends for primary fuel as this may cause overfiring. Overfiring is a condition where excessive temperatures are reached, beyond the design capabilities of the stove. The damage that occurs from overfiring is not covered under the stove warranty.

WARNING: BURNING IMPROPER FUEL (I.E. CHAR- COAL) CAN RESULT IN CARBON MONOXIDE POISON- ING WHICH MAY LEAD TO DEATH!

CARBON MONOXIDE POISONING – EARLY SIGNS OF CARBON MONOXIDE POISONING RESEMBLE THE FLU WITH HEADACHES, DIZZINESS, OR NAU- SEA. IF YOU HAVE THESE SIGNS, GET FRESH AIR AT ONCE! HAVE THE HEATER INSPECTED BY A QUALIFIED SERVICE TECHNICIAN. SOME PEOPLE ARE MORE AFFECTED BY CARBON MONOXIDE THAN OTHERS. THESE INCLUDE PREGNANT WOMEN, PEOPLE WITH HEART OR LUNG DISEASE OR ANEMIA, THOSE UNDER THE INFLUENCE OF

ALCOHOL, AND THOSE AT HIGH ALTITUDES.

WHY SEASONED WOOD?

The key to the success of a good fire that produces heat from a woodstove is the wood. It needs to be well- seasoned natural wood.

What does

Green wood does not burn easily. Attempting to burn green wood often results in a lot of smoke and very little fire. Time is the most important factor in seasoning wood. Ideally the moisture content should be reduced to

PAGE 17